Helicopter box body part welding positioning device with ventilation protection function

A welding positioning and helicopter technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient removal of box parts, affecting the quality of welds, and difficulty in maintaining the shape of the box, so as to improve the quality of welding forming and efficiency, ensuring the quality of welding forming, and avoiding the effect of poor synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

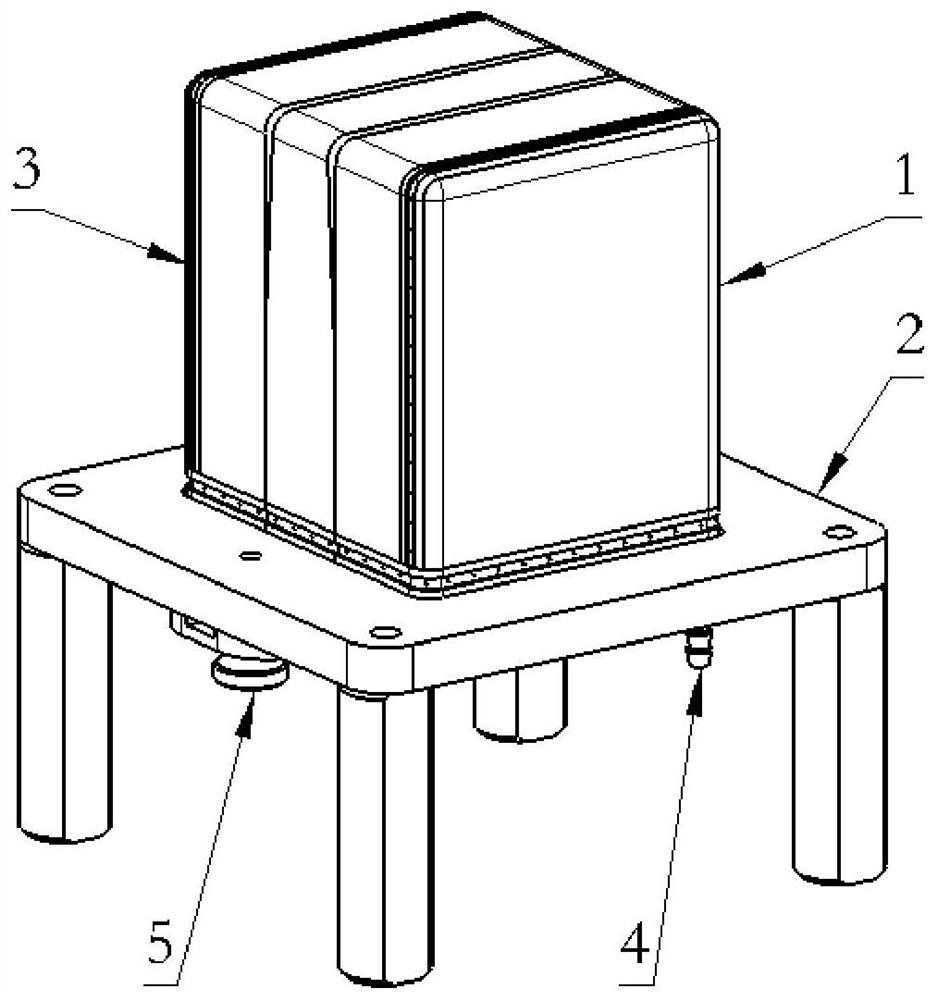

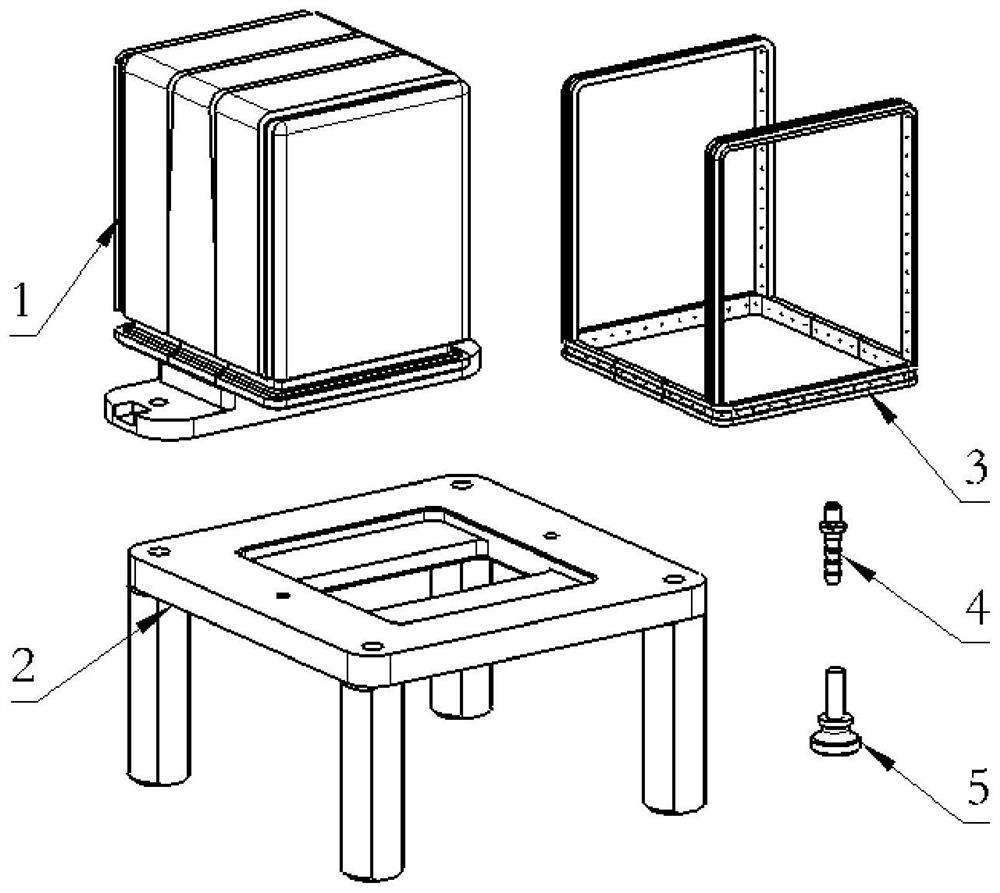

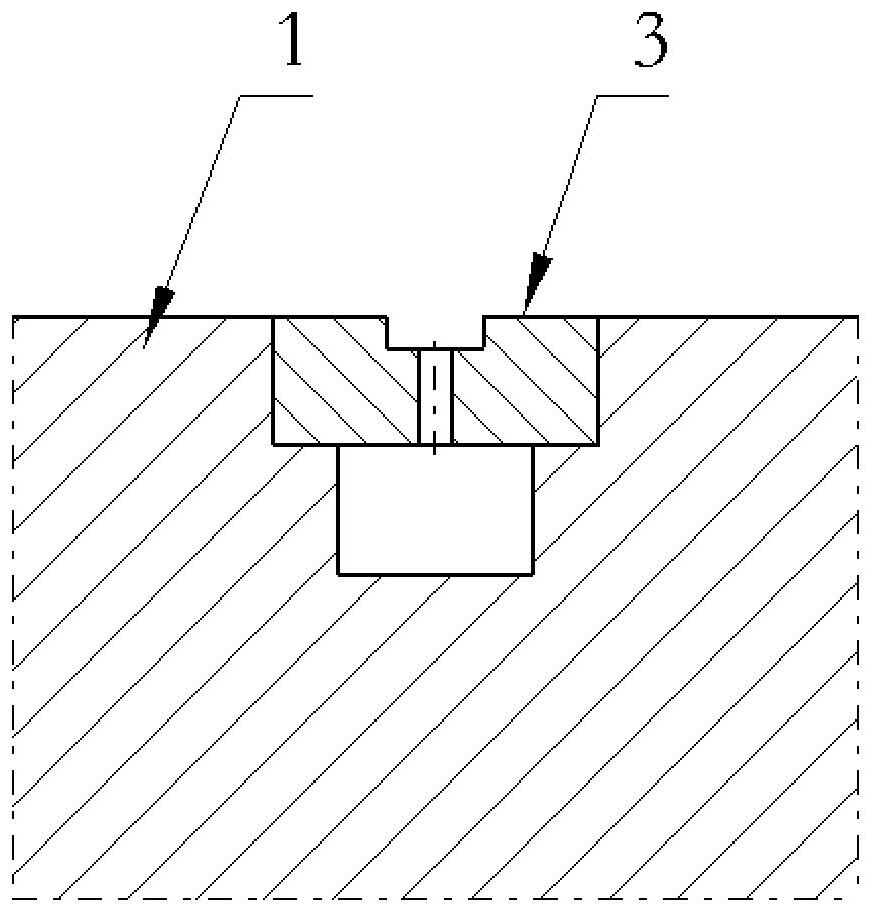

[0021] The present invention is described in detail below in conjunction with accompanying drawing of specification sheet; A kind of welding positioning device of helicopter box body part with ventilation protection is as follows: figure 1 , figure 2 and image 3 As shown, the device mainly includes a positioning core block 1, a positioning base plate 2, a copper pad 3, a connecting gas nozzle 4 and a connecting screw 5; the positioning core block 1 with a ventilating groove structure is used as the positioning main structure, and the positioning core block 1 is installed on The positioning base plate 2 is detachable; the positioning base plate 2 is equipped with a connecting gas nozzle 4 connected to the protective gas, and the protective gas can pass directly into the ventilation groove of the positioning core block 1; the ventilation groove on the positioning core block 1 is equipped with a copper pad 3, Ventilation holes are distributed on the copper pad 3 at a certain i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com