Digital design method of automobile rear windshield glass hot press molding die

A rear windshield and hot-press forming technology, which is applied in glass forming, glass tempering, glass reshaping, etc., can solve the problems of difficult mold development and molding process optimization, long cycle time, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

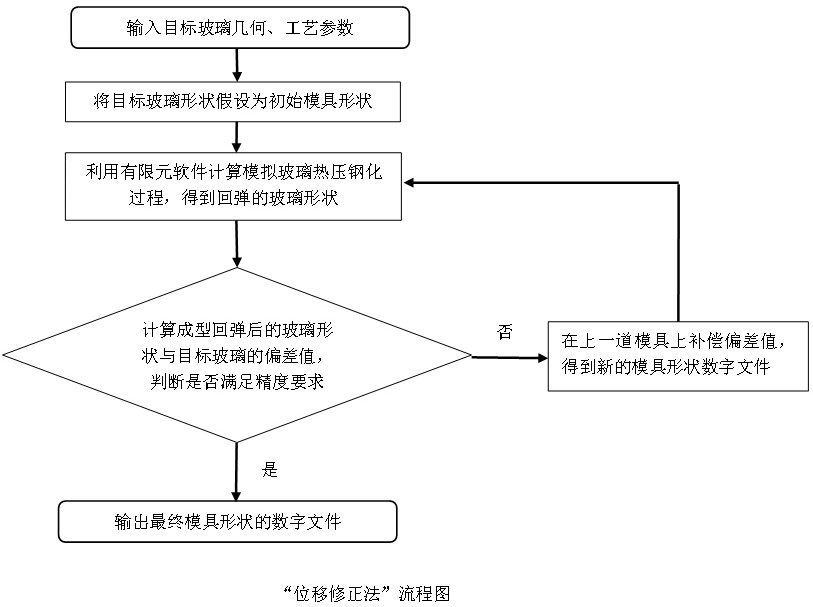

[0038] The present invention will be further described below with reference to the accompanying drawings and embodiments.

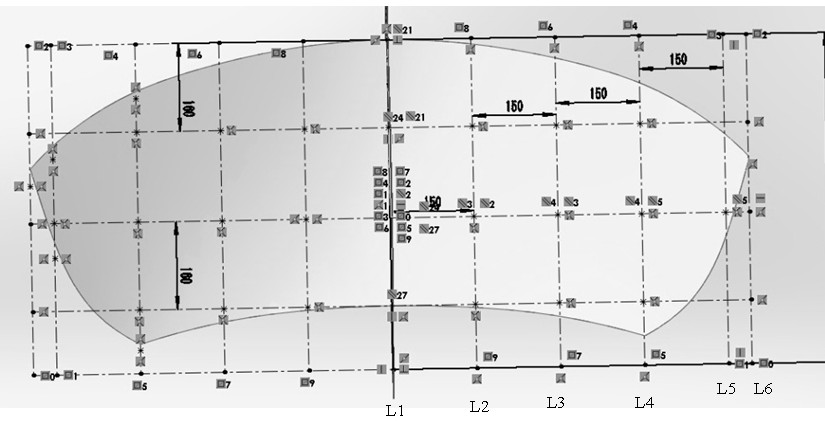

[0039] This embodiment takes the digital design of the mold for the rear windshield of a certain type of automobile as an example, including the following steps:

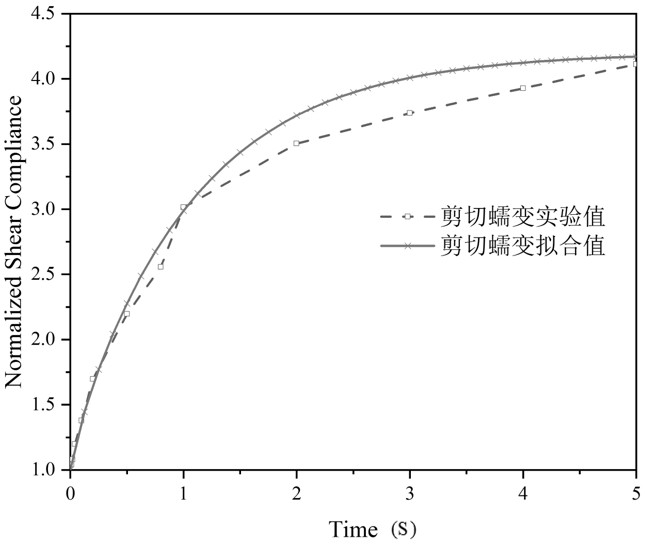

[0040] Considering the viscoelastic properties of the glass material, its three-dimensional transient viscoelastic constitutive equation under large strain is deduced, and its integral form is

[0041]

[0042] where e is the shear modulus, ε is the bulk strain, τ is the reduced time from the non-equilibrium state to the equilibrium state, G is the shear modulus, K is the bulk modulus, t is the real time, I is a unit tensor.

[0043] G(t) and K(t) in the above formula are replaced by Prony series, we get

[0044]

[0045]

[0046] In the formula, G(∞), G i is the shear modulus of the Maxwell element, K(∞), K i is the bulk modulus of the Maxwell element, τ i G Corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com