Laser splitting device for cutting optical glass

An optical glass and laser technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of scrapping optical glass rough embryos, waste of raw materials, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

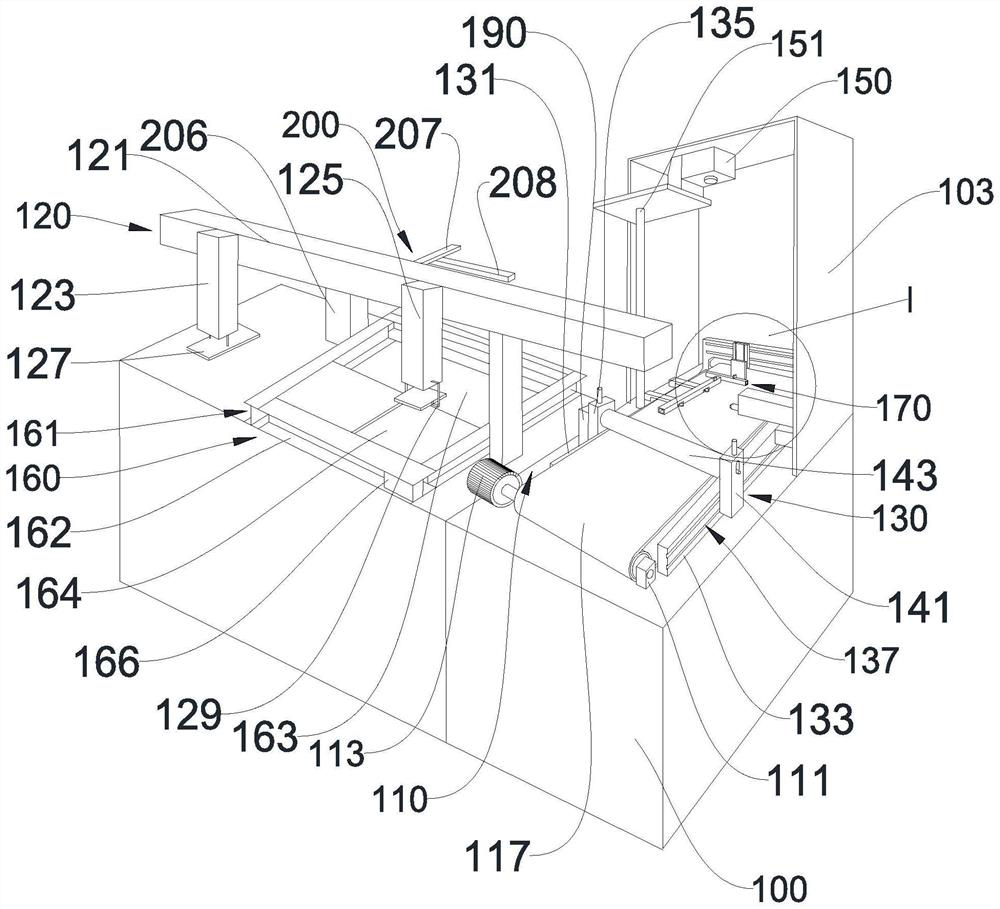

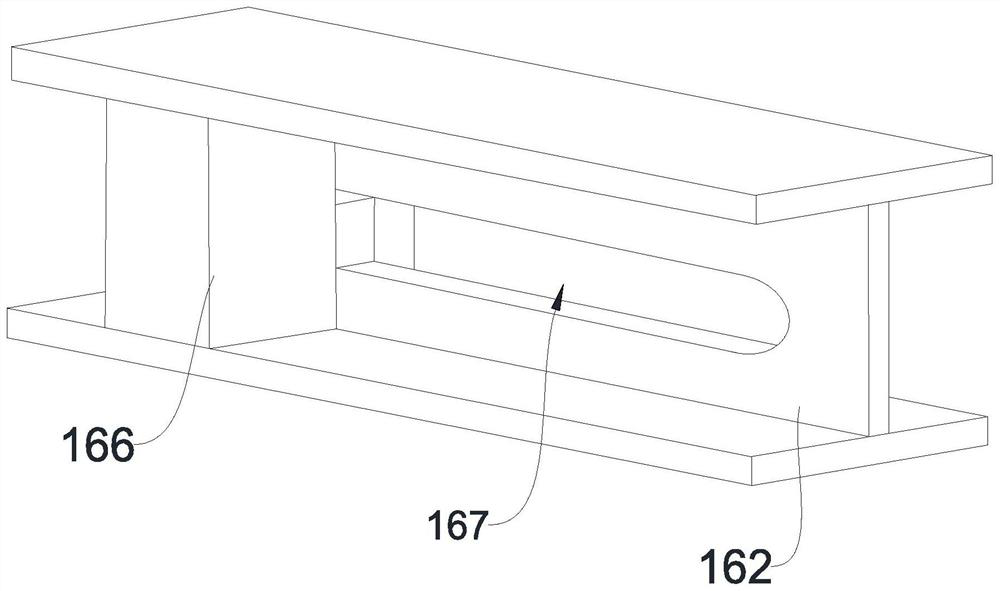

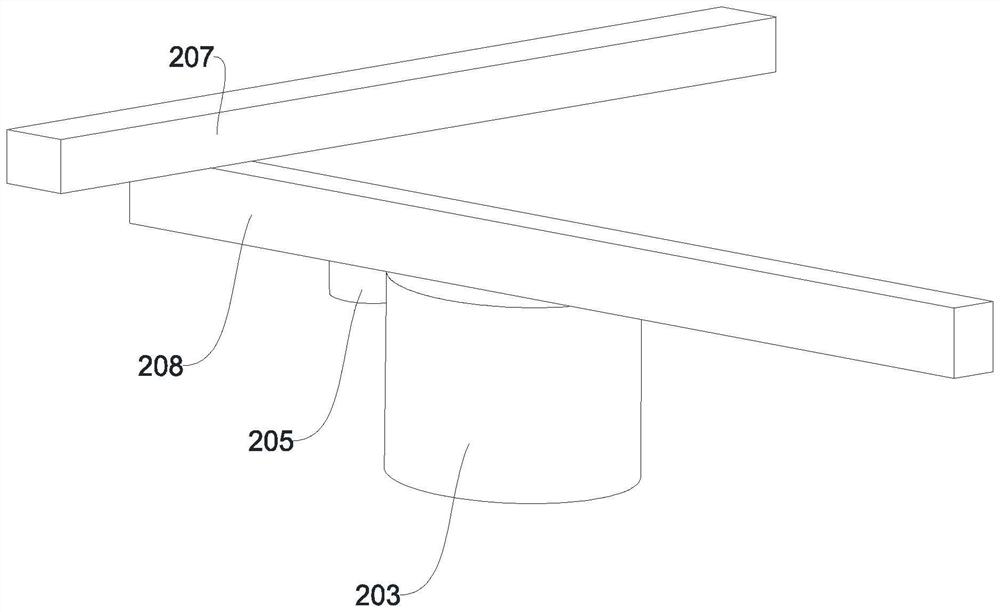

[0030] Please refer to figure 1 As shown, a laser splitting device for cutting optical glass includes a main body 100 and a control system. On the top surface of the main body 100, 120, a first conveying assembly 160, a cutting assembly 200, a second conveying assembly 110, Liquid feeding assembly 130 , secondary cutting heating assembly 150 and positioning assembly 170 . The feeding assembly 120, the first conveying assembly 160, the cutting assembly 200, the second conveying assembly 110, the liquid adding assembly 130, the secondary cutting heating assembly 150 and the positioning assembly 170 are all electrically connected to the control system, and the control system can The program automatically controls the feeding assembly 120 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com