Emulsified asphalt plant-mixed cold-recycled mixture and construction process thereof

A technology for cold recycling of mixtures and emulsified asphalt, applied in the directions of roads, sustainable waste treatment, solid waste management, etc., can solve the problems of insufficient disclosure, no disclosure of mixture composition, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

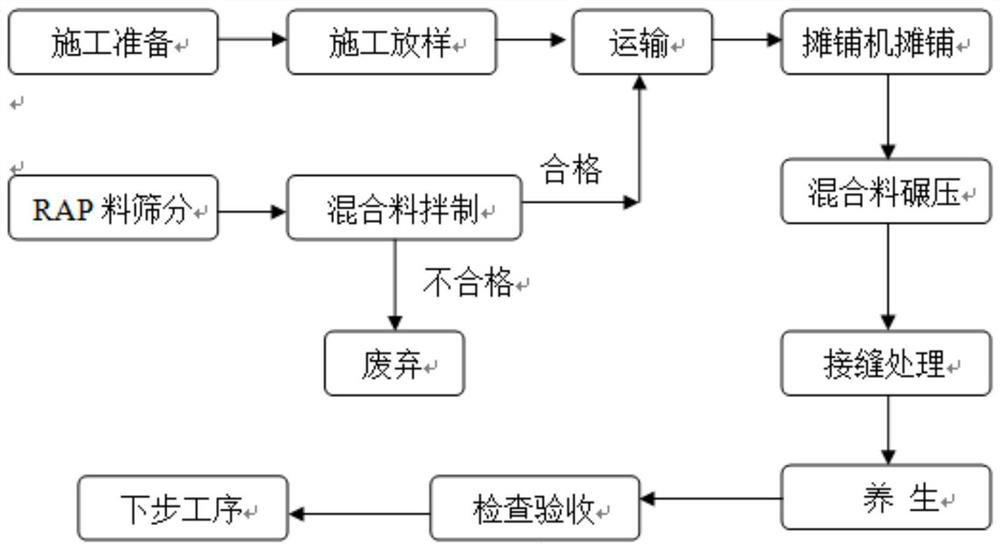

[0063] see figure 1 as well as Figure 6 Shown:

[0064] This embodiment provides an emulsified asphalt plant mixed cold recycled mixture and its construction process, the formula of which includes cold recycled mixture ore, emulsified asphalt and cement;

[0065] The cold recycled mixed material mineral material includes RAP mineral material, aggregates with a particle size of 10-30mm: and mineral powder;

[0066] Described RAP mineral material comprises the RAP mineral material that particle size is 0-5mm, the RAP mineral material that particle size is 5-10mm and the RAP mineral material that particle size is 10-30mm;

[0067] The RAP mineral material whose particle size is 0-5mm: the RAP mineral material with a particle size of 5-10mm: the RAP mineral material with a particle size of 10-30mm: the aggregate with a particle size of 10-30mm: mineral powder: cement: emulsified asphalt=( 28-33)%: (22-25)%: (32-37)%: (8-12)%: (1.8-2.2)%: (1.2-1.8)%: (2.6-3.8)%;

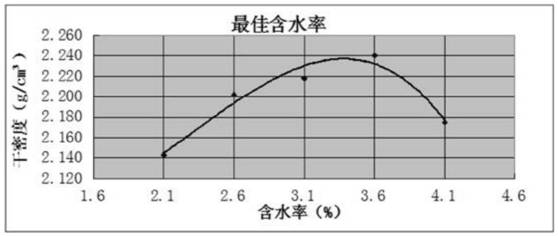

[0068] The p...

Embodiment 2

[0113] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that

[0114] The distribution ratio of the components in the cold recycled mixture is as follows: RAP mineral material with a particle size of 0-5 mm: RAP mineral material with a particle size of 5-10 mm: RAP mineral material with a particle size of 10-30 mm: a particle size of 10 mm -30mm aggregate: mineral powder == 30: 23: 35: 10: 2; cold recycled mixture mineral material: emulsified asphalt: cement = 100: 3.3: 1.5. Determine the best amount of emulsified asphalt and take 2.6%, 2.9%, 3.2%, 3.5%, 3.8% to make and secondary molding test pieces, and test the bulk density, void ratio, splitting strength and other indicators;

[0115] From attached Figure 9 It can be seen from the table test results that the amount of emulsified asphalt OEC1 corresponding to the maximum bulk density of the cold recycled mixture is 3.2%, and under the premise of satisfying the porosity of 9...

Embodiment 3

[0117] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that

[0118] After the construction of the emulsified asphalt factory-mixed cold recycled mixture layer is completed, the entire line will take 1-3km as an assessment section for acceptance. as attached Figure 4 As shown, check and accept according to the provisions in the table; to ensure the quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com