Aluminum foil as well as manufacturing method and application thereof

A manufacturing method and technology of aluminum foil, applied in the direction of metal rolling, can solve the problems of aluminum foil that is not suitable for flexible packaging and its preparation, and achieve the effect of improving surface cleanliness and improving forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

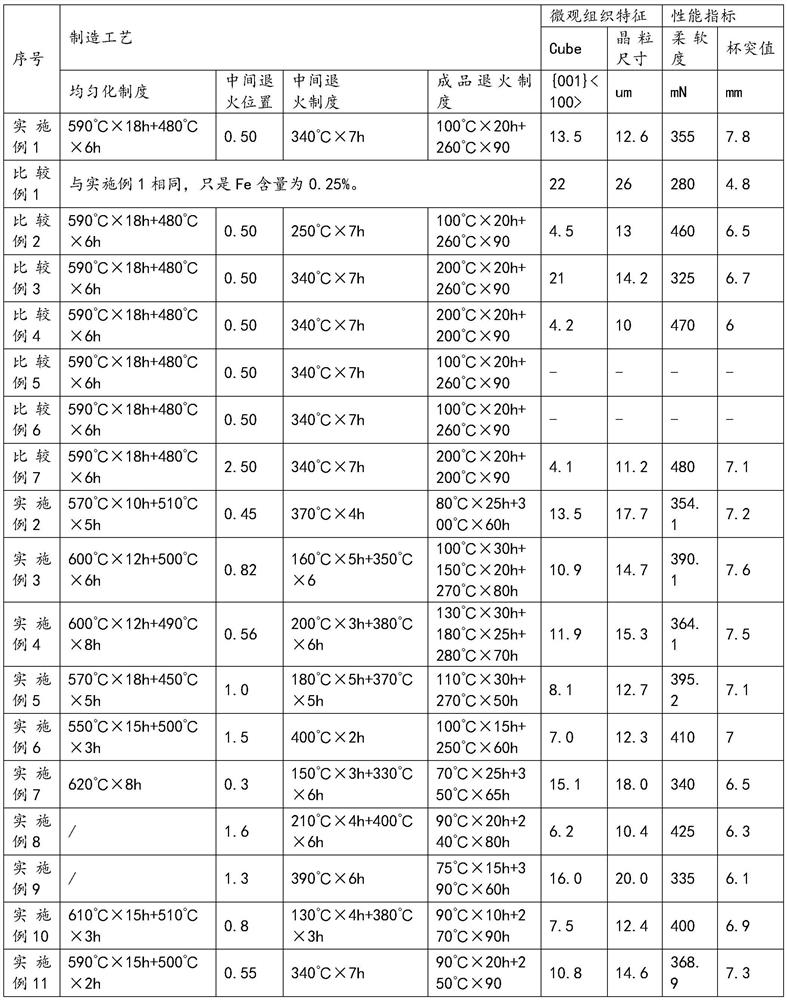

Examples

Embodiment approach

[0056] According to one embodiment of the present invention, the manufacturing method of the aluminum foil includes the following steps:

[0057] Intermediate annealing step: performing intermediate annealing on the aluminum foil blank to obtain an annealed aluminum foil blank,

[0058] rolling step: rolling the annealed aluminum foil blank to obtain aluminum foil (also called semi-finished aluminum foil), and

[0059] Finished annealing step: performing finished annealing on the semi-finished aluminum foil to obtain aluminum foil (also called finished aluminum foil).

[0060] According to an embodiment of the present invention, in the manufacturing method of the aluminum foil, from the perspective of realizing the best technical effect of the present invention, the thickness of the aluminum foil blank is preferably 0.1-2.0 mm, more preferably 0.3-1.0 mm.

[0061] According to one embodiment of the present invention, in the manufacturing method of the aluminum foil, the inter...

Embodiment 1

[0093] A packaging aluminum foil, the aluminum foil is made of the following components by mass percentage:

[0094] Si is 0.048%, Fe is 1.24%, Cu is 0.014%, Mn is 0.011%, Mg is 0.005%, Zn is 0.012%, Cr is 0.0007%, Ti is 0.01%, V is 0.0014%, and the balance is Al and not Avoid impurities.

[0095] The manufacturing method of described aluminum foil comprises the following steps:

[0096] 1) Semi-continuous ingot homogenization treatment

[0097] Sawing the two ends and the remaining four sides of the semi-continuously cast rectangular ingot of the material, the sawing amount of the end and the side is 30mm and 15mm respectively, and then homogenize and keep warm in a heating furnace at 590°C After 18 hours, it was incubated at 480°C for 6 hours.

[0098] 2) Hot rolling

[0099] Under the lubrication of aqueous emulsion with a pH value of 7.5 and a temperature of 45-50°C, use a 1+1 train with a roll surface roughness of 0.63-1.25μm to roll the ingot at a temperature of 500°...

Embodiment 2

[0130] A packaging aluminum foil, which is made of the following components by mass percentage:

[0131] Si is 0.079%, Fe is 1.05%, Cu is 0.049%, Mn is 0.039%, Mg is 0.008%, Zn is 0.02%, Cr is 0.0016%, Ti is 0.007%, V is 0.0009%, and the rest is Al and not Avoid impurities.

[0132] The manufacturing method of described aluminum foil comprises the following steps:

[0133] 1) Semi-continuous ingot homogenization treatment

[0134] Sawing the two ends of the semi-continuous rectangular ingot made of the materials of the above components, the sawing amount is 30mm, and the other four sides are respectively two large faces and two small faces; Each small face is milled, and the cutting amount of each face is 15mm, and then the aluminum ingot is sent to a heating furnace at 570°C for homogenization treatment and kept for 10 hours, and then kept at 510°C for 5 hours.

[0135] 2) Hot rolling

[0136] Using work rolls with a surface roughness of 0.63-1.25 μm in 1+2 train hot roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com