Wire cord fabric detection and calibration device and detection and calibration method

A technology for detecting and calibrating devices and steel cords, which is applied in the direction of material magnetic variables, etc., can solve problems such as different magnetic fields, different original outputs of array magnetic sensitive elements, and difficult detection of image defects, so as to improve accuracy and reliability, and effectively The effect of outstanding information and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

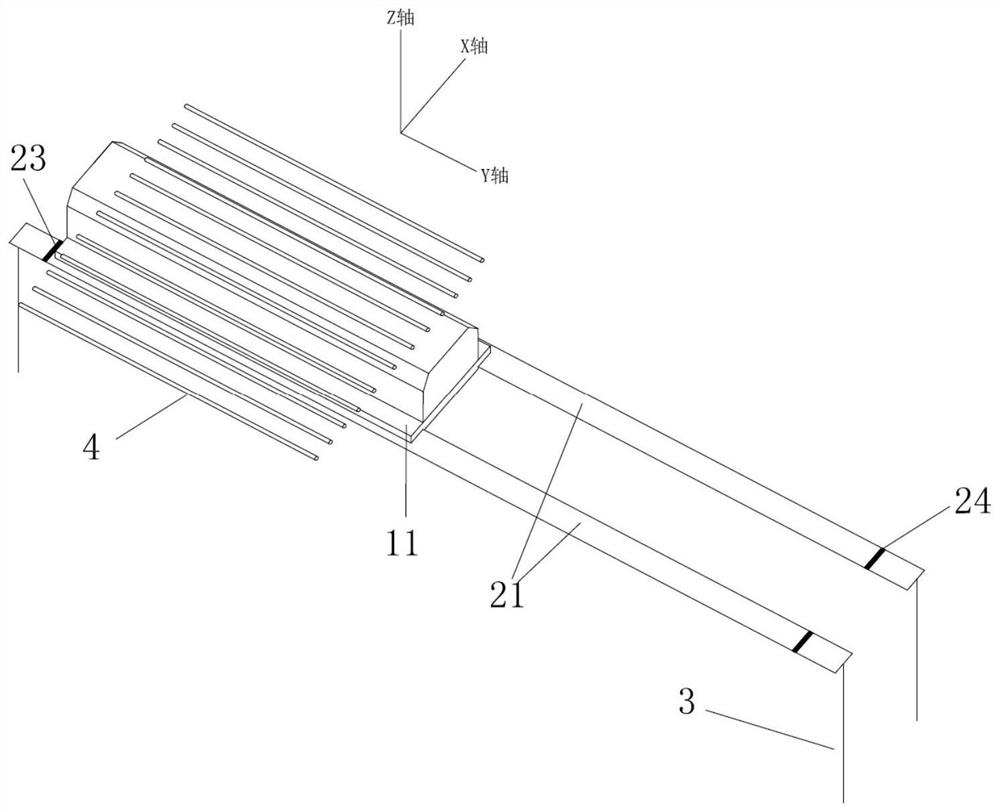

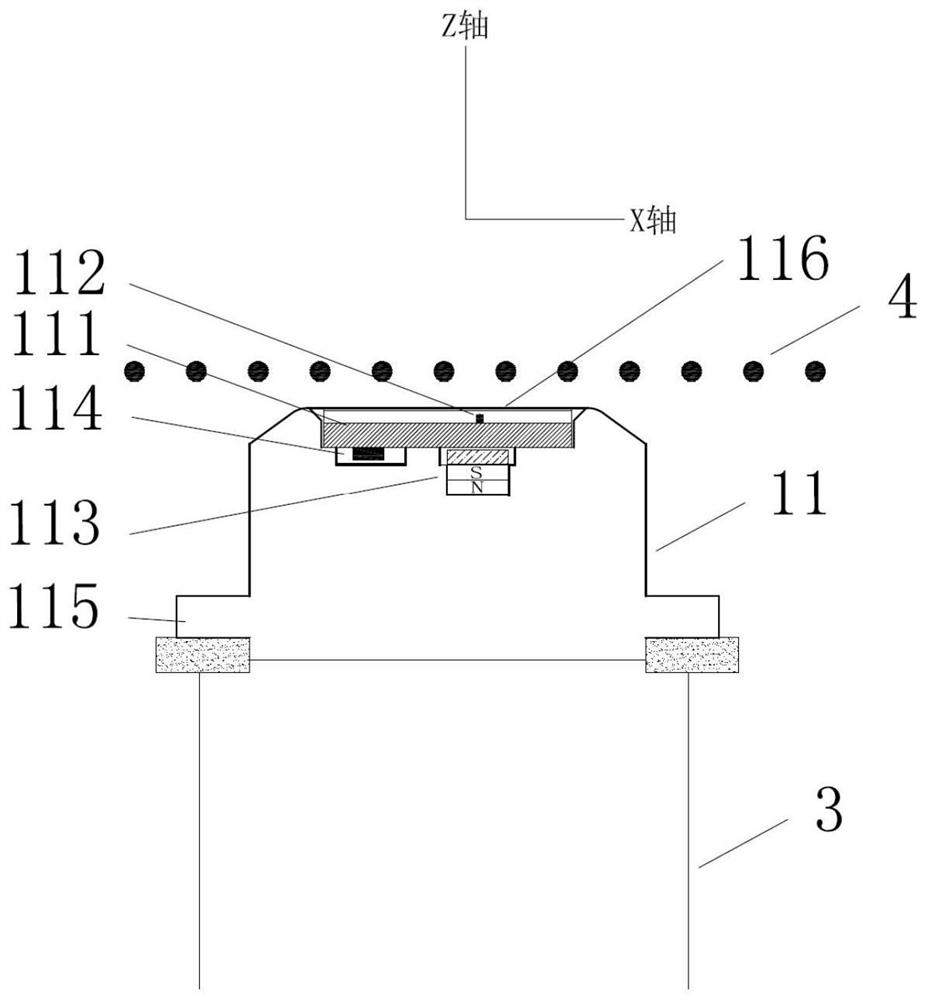

[0087] Such as Figure 4 , Figure 5 As shown, this embodiment provides a steel cord detection and calibration device, including a magnetic sensor module 11 , a first slide rail 21 , a sliding mechanism 6 , a receiving member 5 and a bracket 3 .

[0088] The magnetic sensor module 11 includes a substrate 111 made of PCB material. The substrate 111 is parallel to the width of the steel cord 4. On the surface of the substrate 111 facing the steel cord 4, 216 magnetic sensors are arranged at equal intervals of 0.5 mm along the Y axis. Component 112 forms an effective scanning width of 108 mm and obtains detection signals and calibration signals, both of which are magnetic field signals, specifically, voltage signals reflecting the magnitude of the magnetic field; the surface of the substrate 111 facing away from the side of the steel cord 4 A magnetic unit 113 facing away and a processing unit 114 are provided, the magnetic unit 113 facing away comprises a plurality of magnets a...

Embodiment 2

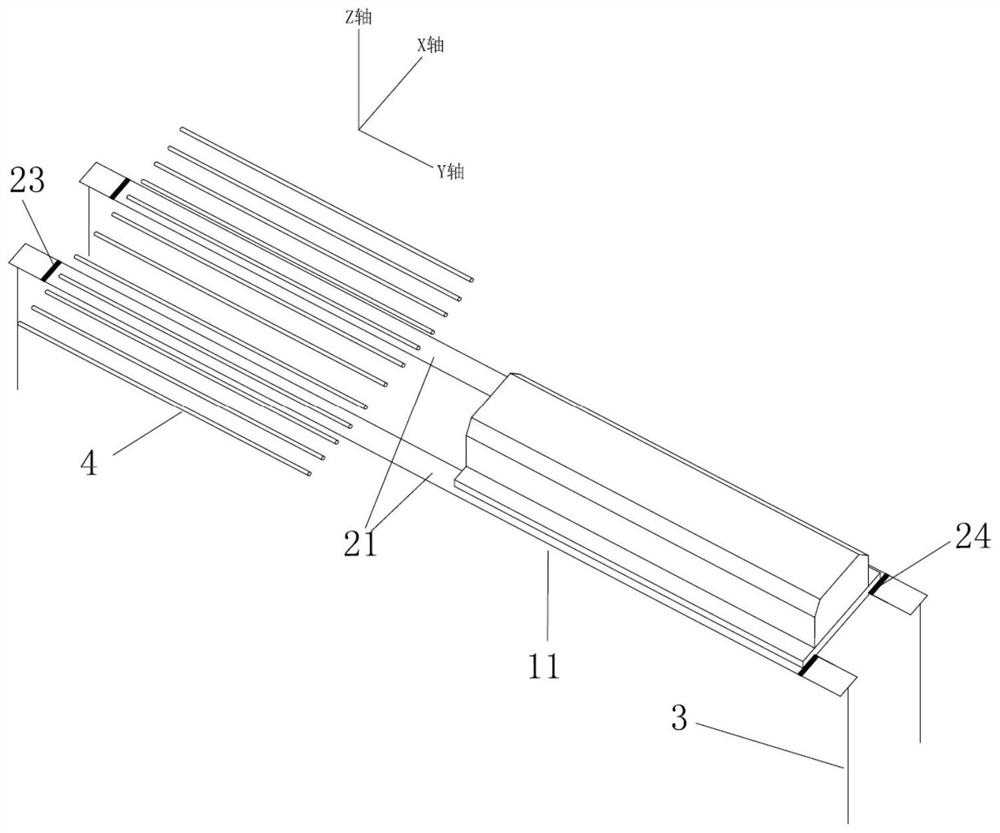

[0110] Embodiment 2 provides another embodiment of the steel cord detection and calibration device of the present application, Figure 6 It is a schematic diagram of the present embodiment in the detection state, Figure 7 It is a schematic diagram of this embodiment in a calibration state, Figure 8 It is a side view of this embodiment.

[0111] Such as Figure 6 to Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that a first opposing magnetic module 12 and a second slide rail 22 are added, and the first opposing magnetic module 12 is arranged on a side of the steel cord 4 facing away from the magnetic sensor module 11. side, including the first opposing magnetic unit 121 arranged along the Y-axis direction and the first opposing magnetic module frame 122 for inserting and fixing the first opposing magnetic unit 121, the first opposing magnetic module frame 122 Made of non-magnetic and non-magnetized materials; the second slide rail 22 is para...

Embodiment 3

[0114] Embodiment 3 provides another embodiment of the steel cord detection and calibration device of the present application, Figure 9 It is a schematic diagram of the present embodiment in the detection state, Figure 10 Schematic diagram of this implementation in calibration.

[0115] Such as Figure 9 , Figure 10 As shown, the difference between this embodiment and Embodiment 2 is that a second opposing magnetic module 13 is added. In this embodiment, the first opposing magnetic module 12 is positioned at the detection position, and the second opposing magnetic module 13 is positioned At the calibration position, it includes the second opposing magnetic unit arranged along the Y axis and the second opposing magnetic module frame for placing and fixing the second opposing magnetic unit. The second opposing magnetic module frame is made of non-magnetic The first magnetic unit and the second magnetic unit are both of strong magnetic structure and have the same magnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com