Method for regulating nitration substitution degree of nitrocellulose

A technology of nitrocellulose and nitrification, applied in instruments, analytical materials, measuring devices, etc., can solve problems such as uneven fluorescence background, reduce background noise, overcome high green fluorescence background and uneven fluorescence background, background noise low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of nitrocellulose with precisely adjusted degree of nitration:

[0033] (1) Preparation of nitrocellulose with a high degree of substitution:

[0034] A. Accurately measure 30-45 mL of fuming nitric acid and 50-80 mL of concentrated sulfuric acid, mix them and place them on a magnetic stirrer;

[0035] B. Accurately weigh 4 g of cellulose and add it to the mixture of fuming nitric acid and concentrated sulfuric acid, and react for 1 to 4 hours to make the nitration reaction as complete as possible and the degree of substitution as high as possible;

[0036] C. Inject the reaction solution into 2 L of ultrapure water, and add sodium carbonate while stirring until no carbon dioxide bubbles are produced;

[0037] D. Precipitate overnight, discard the supernatant, boil the precipitate with 2% sodium carbonate solution for 20 min, adjust the pH to neutral with hydrochloric acid, and centrifuge in a 50 mL centrifuge tube for 5 times, centrifuge the precipitate a...

Embodiment 2

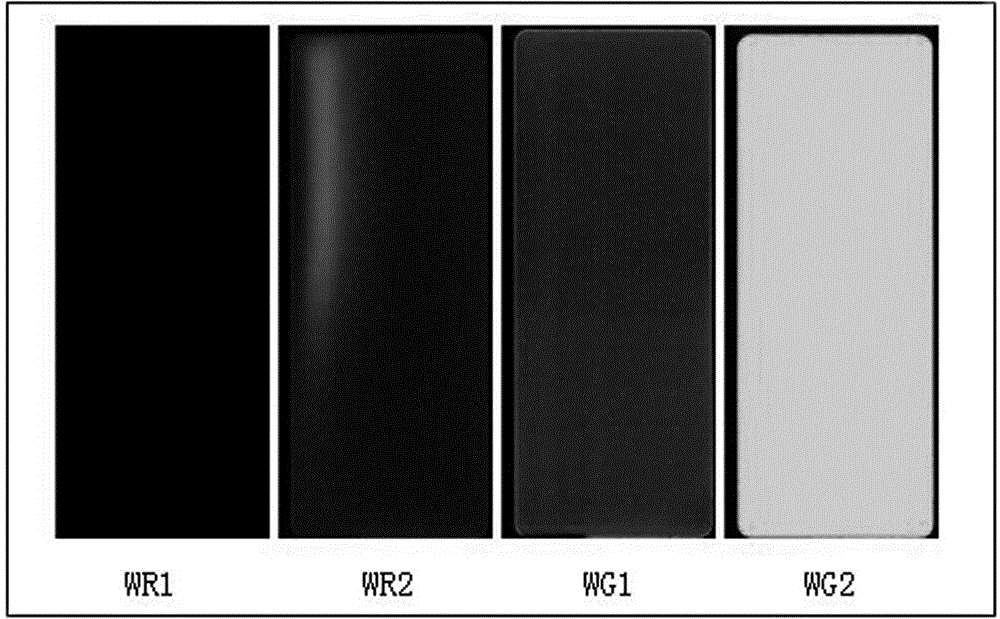

[0050] Comparison of background intensity and uniformity for red and green fluorescent channels:

[0051] (1) Use nitrocellulose obtained by accurately adjusting the degree of nitration to make a nitrocellulose substrate: weigh 0.2-1 g of nitrocellulose and dissolve it in 4-25 mL of acetone, then add 1-3 mL of isopropanol , 1 to 5 mL of methanol, and 0.1 to 0.5 mL of water were used to form a film-forming liquid, and the film-forming liquid was evenly coated on a glass slide with a film applicator to prepare the nitrocellulose substrate of the present invention.

[0052] (2) Take each of the substrate made by the present invention and the Whatman substrate, scan with an Axon GenePix 4200AL fluorescence scanner, and compare the substrate made by the present invention with the Whatman substrate to check the difference in background uniformity and background intensity . When scanning, the signal amplification uses the same setting. When displaying the visual effect of the backgro...

Embodiment 3

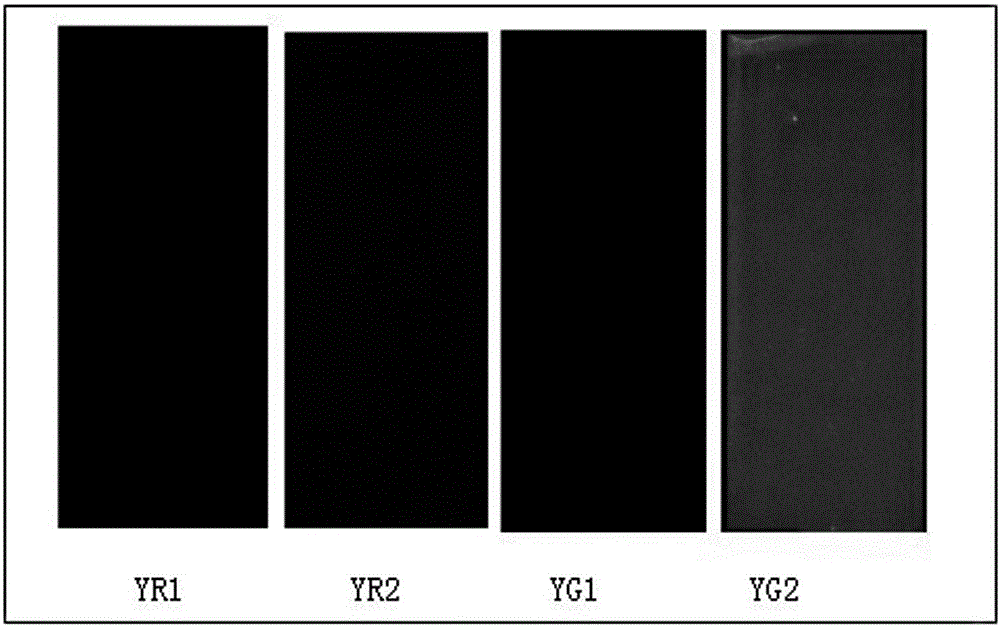

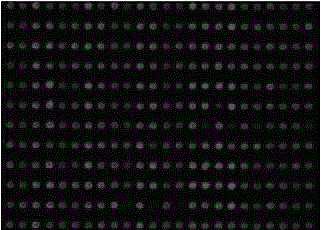

[0060] Comparison of background noise for red and green fluorescent channels:

[0061] (1) Use nitrocellulose obtained by accurately adjusting the degree of nitration to make a nitrocellulose substrate: weigh 0.2-1 g of nitrocellulose and dissolve it in 4-25 mL of acetone, then add 1-3 mL of isopropanol , 1 to 5 mL of methanol, and 0.1 to 0.5 mL of water were used to form a film-forming liquid, and the film-forming liquid was evenly coated on a glass slide with a film applicator to prepare the nitrocellulose substrate of the present invention.

[0062] (2) According to the method disclosed in the literature of Diagnostic markers of ovarian cancer by high-throughput antigen cloning and detection on arrays published by Chatterjee et al. in 2006, the antigen protein clone library was prepared, and two 384-well plates were prepared with this clone library, with a total of 768 antigenic protein marker samples. Use the ArrayJet Marathon (Arrayjet Ltd., Edinbough, Scottland) spottin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com