Edible granular ice cream forming method integrating multi-layer segmentation technology and pressing technology

A molding method and ice cream technology, applied in applications, frozen desserts, food science, etc., can solve the problems of single product taste, not rich enough taste, uneven spraying of chocolate, etc., to achieve the effect of enhancing the feeding effect and enhancing the spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

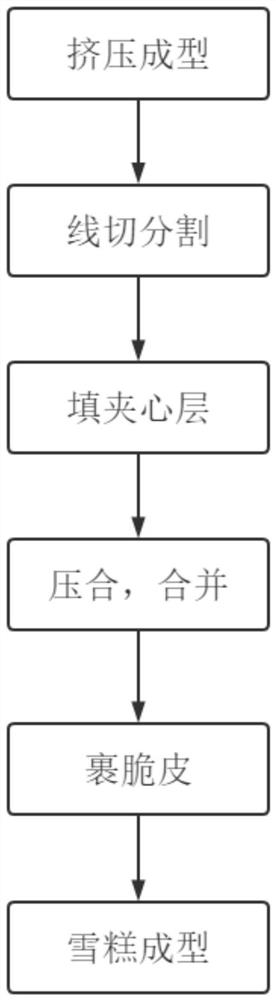

[0048] see Figure 7 , a method for forming edible granular ice cream with multi-layer segmentation technology and pressing technology, comprising the following steps:

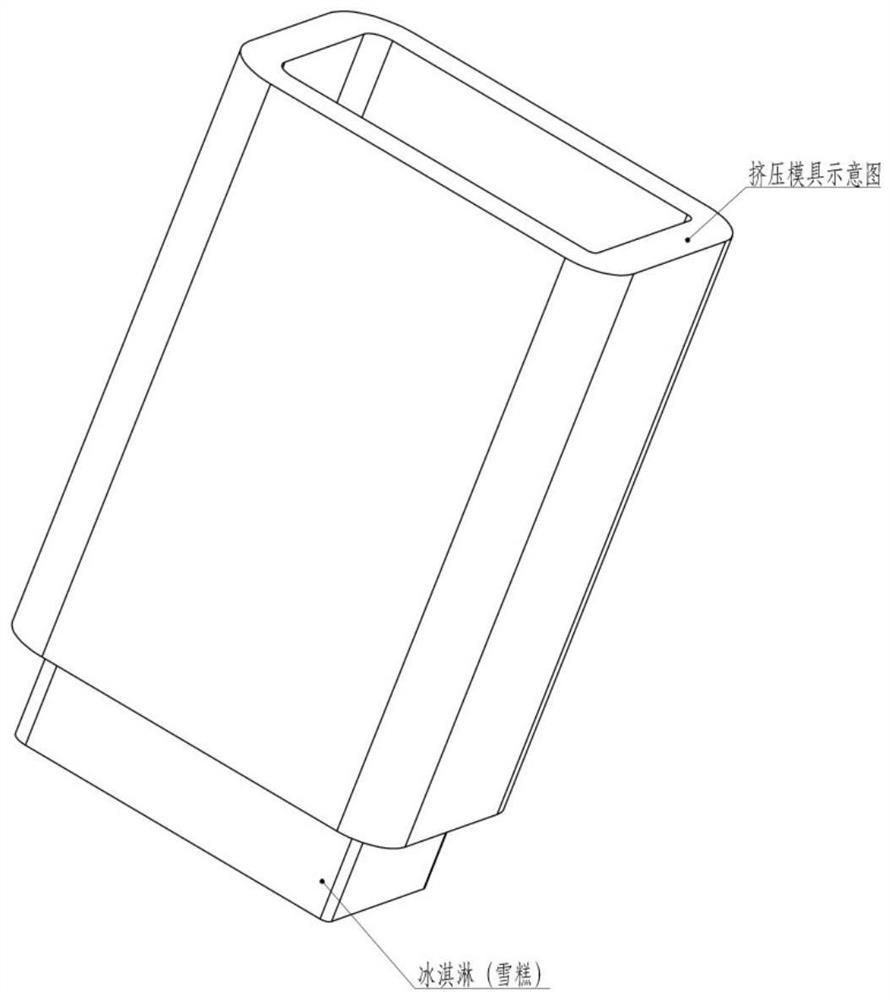

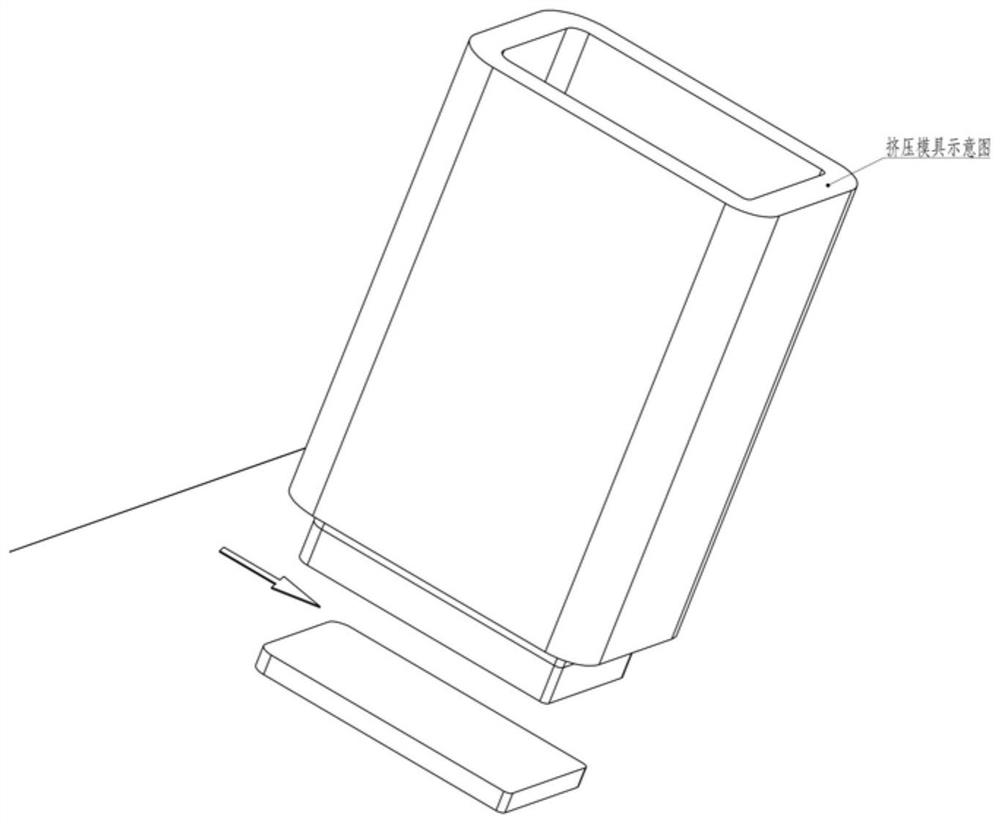

[0049] S1, first take the ice cream and the ice cream mold, and squeeze the ice cream into the ice cream mold to make it shape, then use a thinner linear object to cut the ice cream body on the ice cream mold along the cross section, and cut it into multiple pieces layer;

[0050] S2. Take the multi-layer cake body in S1, and add auxiliary particles such as granules to the cut surface of the cake body, and then spray chocolate on the cut surface by a spraying device to form a sandwich layer;

[0051] S3. Then press the layers together under the ultra-low temperature of liquid nitrogen, so that the chocolate and particle layers are evenly distributed. After the pressing is completed, put the pressed edible particle ice cream into the crispy pulp for wrapping. To obtain the finished product of edible granule i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com