Portable tunnel blasting dust removal device

A dust removal device, a portable technology, applied in safety devices, dust prevention, use of liquid separation agent, etc., can solve the problems of low suction efficiency, unfavorable personnel operation, tunnel soaking, etc., and achieve good foaming effect and simple use , to avoid the effect of wasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

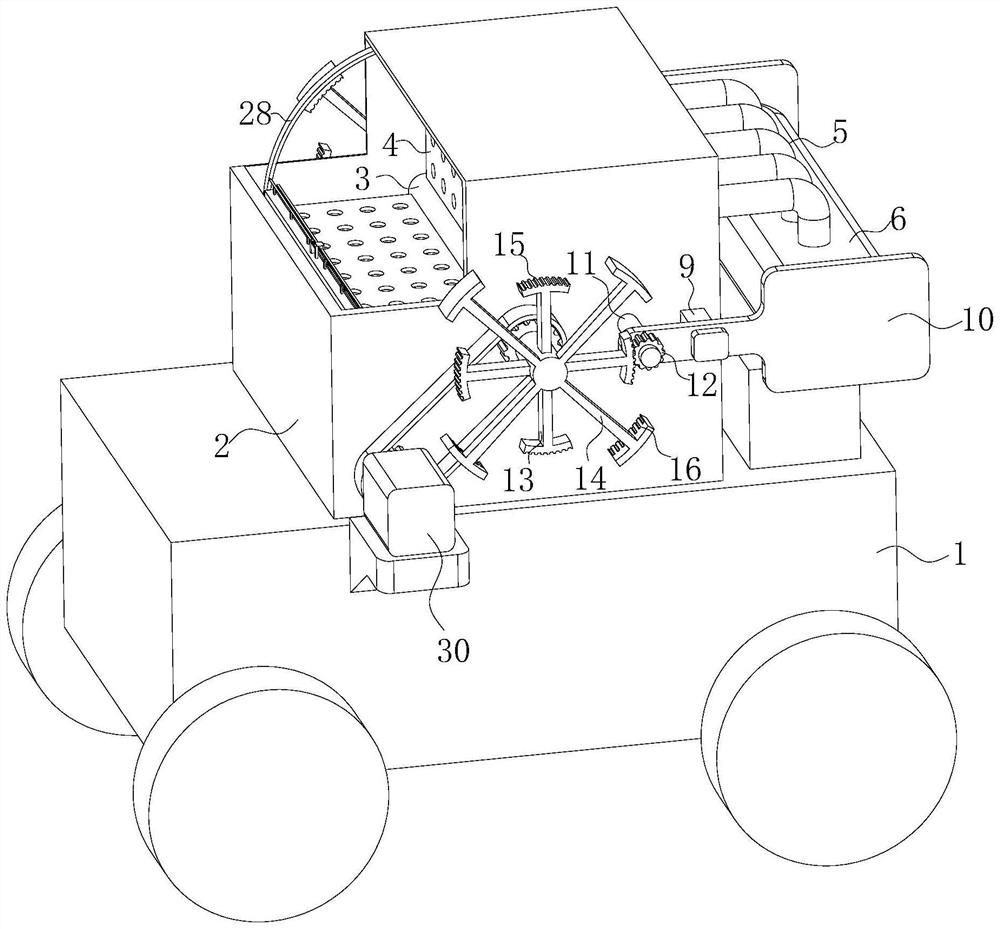

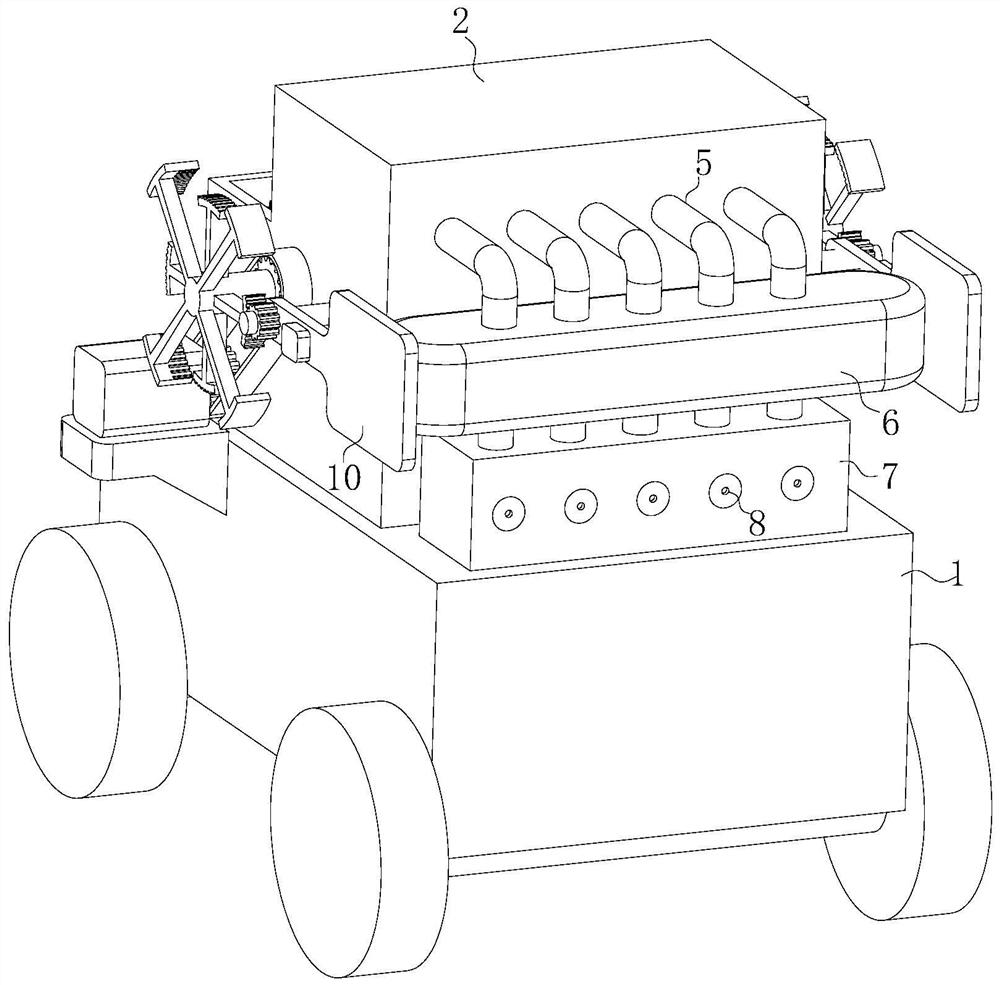

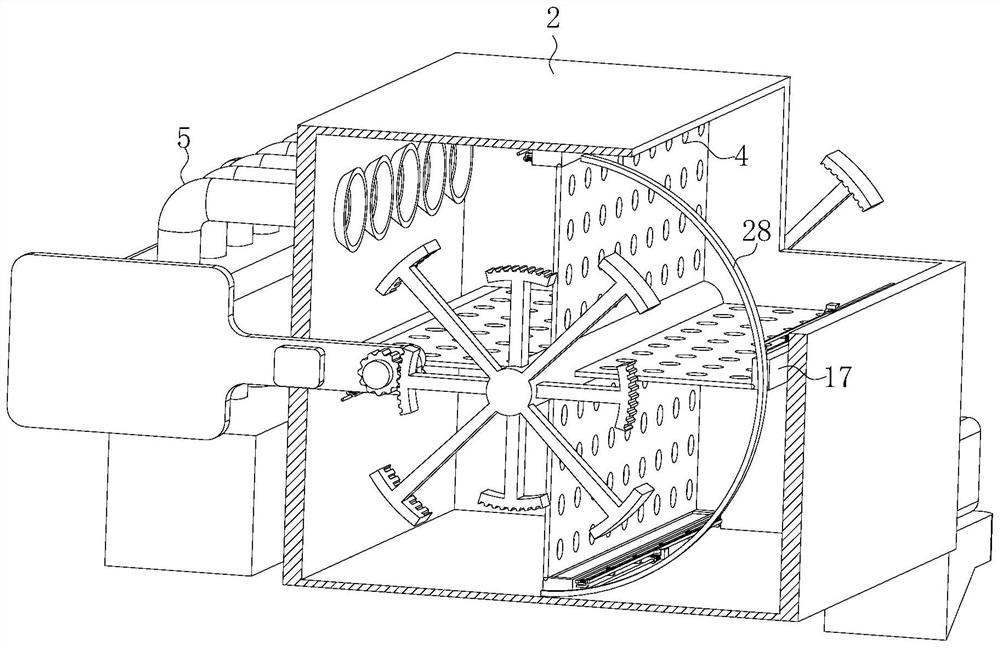

[0029] see Figure 1-8 , the present invention provides a technical solution: a portable tunnel blasting dust removal device, including a mobile base 1, the top of the mobile base 1 is fixedly connected with a discharge box 2, and the inner side of the discharge box 2 is connected with a dipping material for rotating and dipping Mechanism, the right side of the discharge box 2 is provided with a blowing mechanism that is used to agitate and blow air when the dipping mechanism rotates to a vertical state after dipping in the material, and the dipping mechanism cooperates with the blowing mechanism to perform stable blowing in the discharge box 2. bubble work;

[0030] The dipping mechanism includes a first rotating shaft 3, the first rotating shaft 3 is rotatably connected in the discharge box 2, and the outer surface of the first rotating shaft 3 is fixedly connected with a number of dipping net plates 4 distributed in a circle, and the net plates are used to discharge the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com