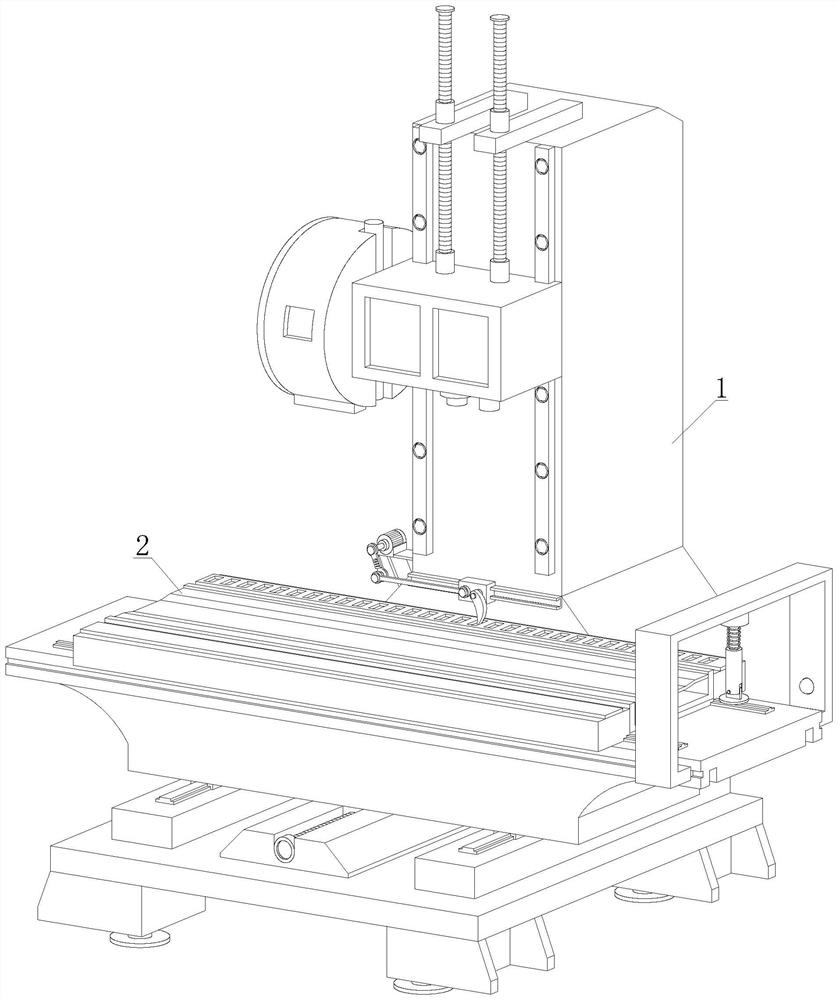

Progressive die stamping device and method for mounting surface of vertical column tool magazine of numerical control machine tool

A technology of numerical control machine tools and stamping devices, which is applied in the field of stamping devices, can solve problems such as poor use effects, and achieve the effect of easy adjustment and two-way adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

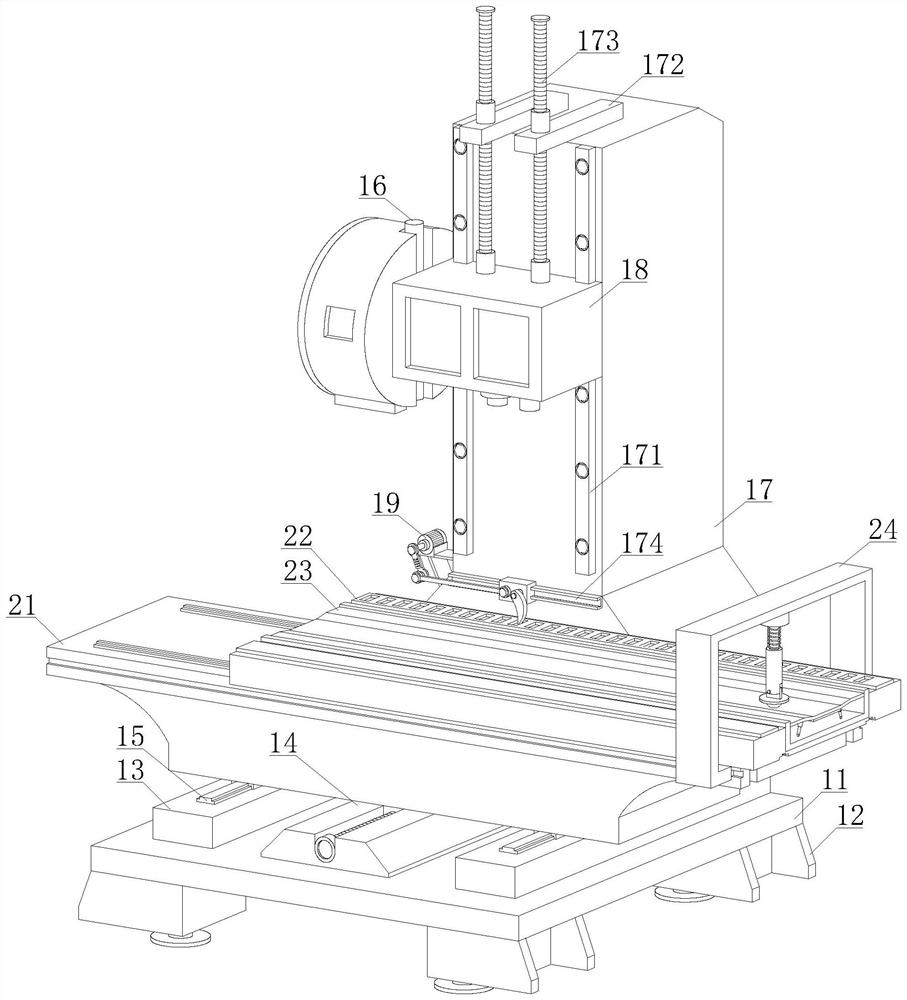

[0043] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for a continuous die stamping device on the mounting surface of a column tool magazine of a CNC machine tool, comprising the following steps:

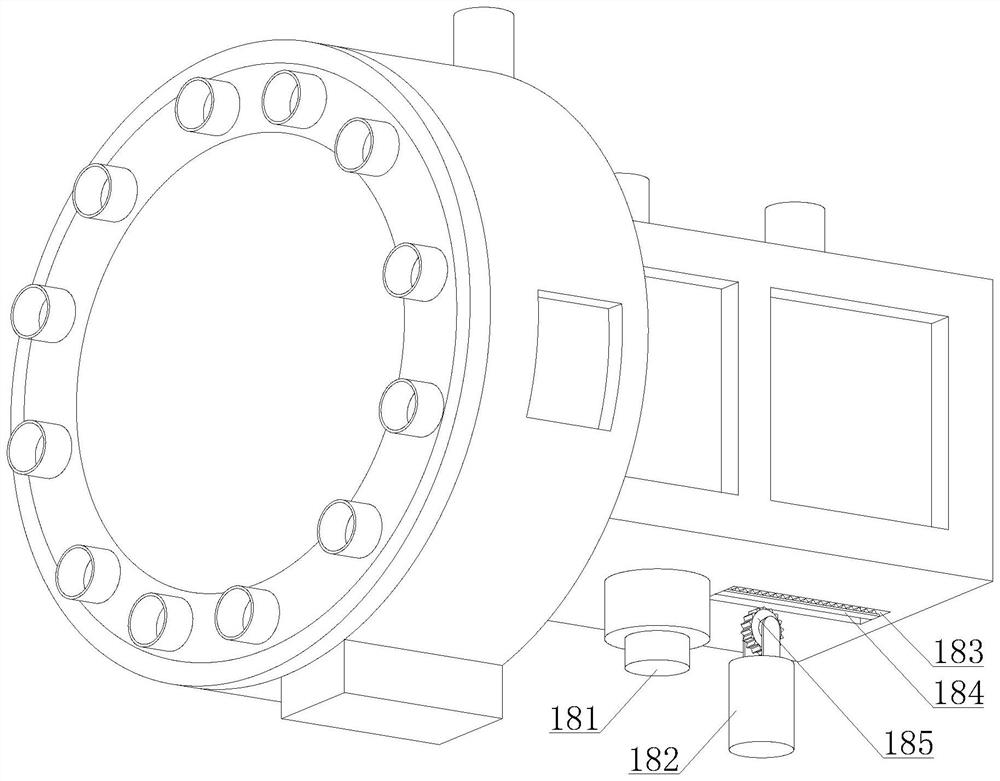

[0044] Step 1: The operator places the workpiece on the upper surface of the load-bearing plate 233, connects the second connecting rod 195 and the third connecting rod 197 with an appropriate length, starts the motor to make the third connecting rod 197 rotate, and the third connecting rod 197 rotates. The rotation of the rod 197 drives the displacement of the first connecting rod 194, and makes the movable part 191 reciprocate along the second slide rail 174. When the movable part 191 reciprocates, one end of the cam 193 is clamped in the slot 225 and pushes the stabilizing block 221 to make it uninterrupted to carry out the promotion work;

[0045] Step 2: Set the distance between the positioning...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap