Pneumatic spiral spline grinding device

A helical spline and grinding device technology, which is applied in the direction of gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of unguaranteed coaxiality of the spline secondary axis, low efficiency, and inability to achieve manual grinding, etc., to achieve The effect of improving grinding precision and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

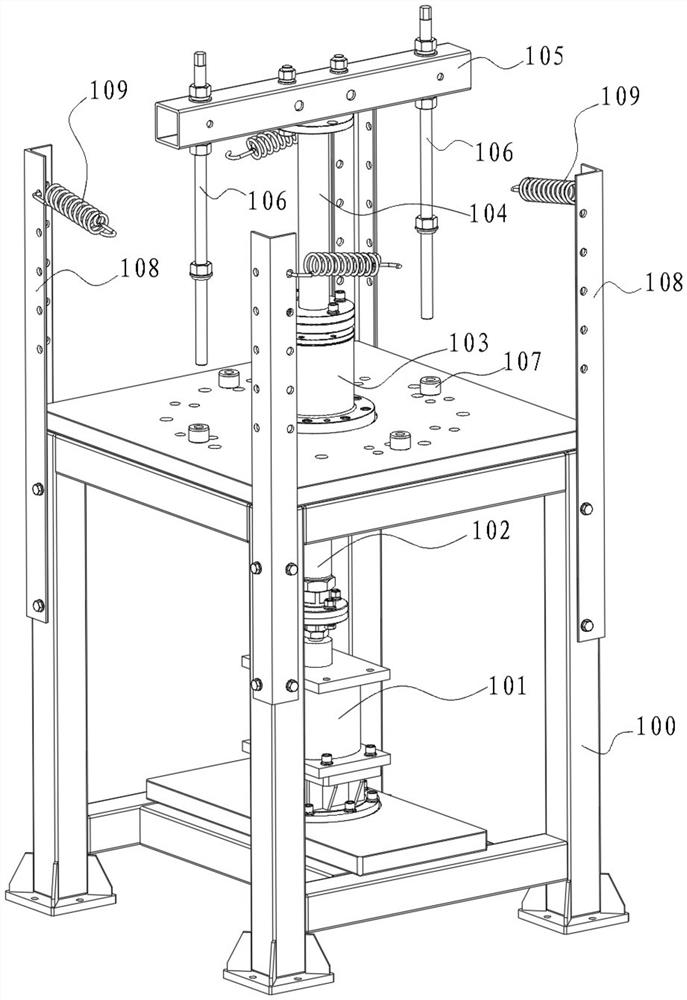

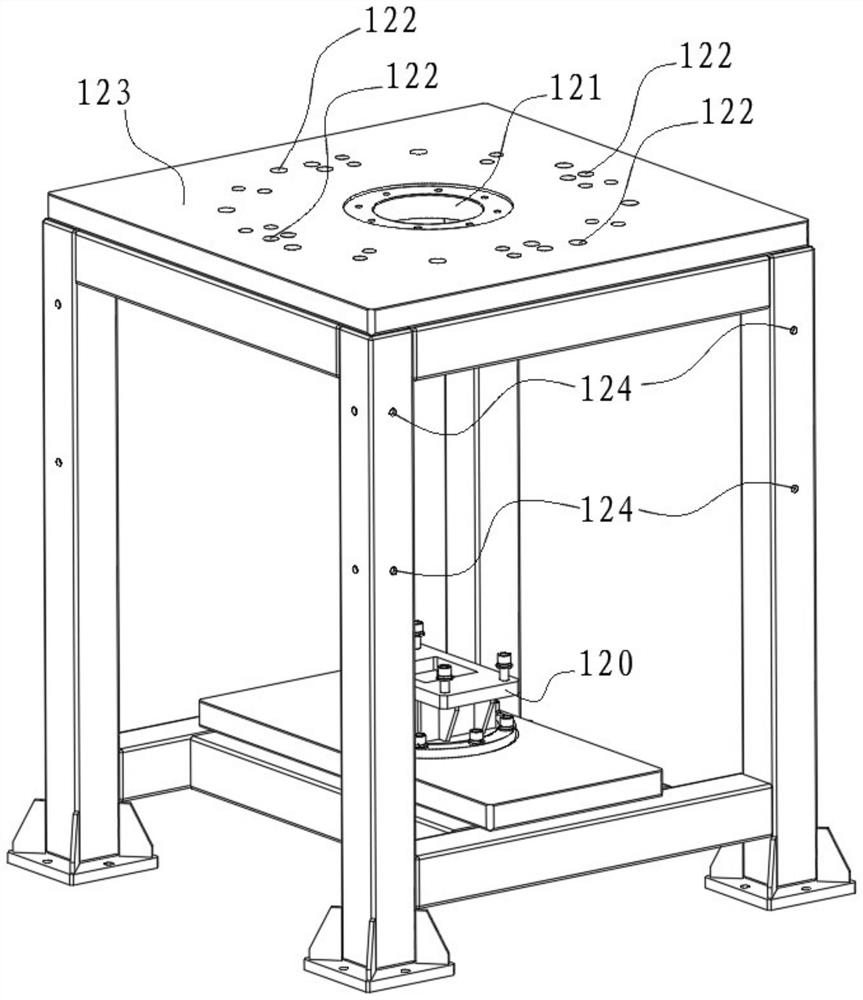

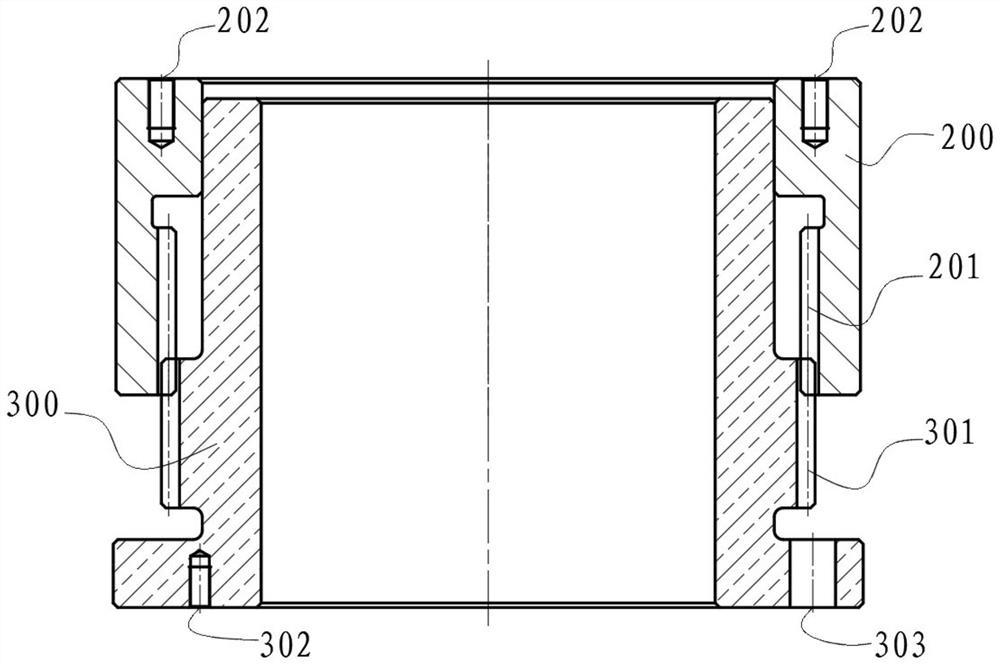

[0025] The pneumatic spiral spline grinding device is mainly composed of a grinding table 100, a cylinder 101, a guiding mechanism mandrel 102, a guiding mechanism outer casing 103, a connecting cylinder 104, a beam 105, and a connecting screw 106. Such as figure 1 , figure 2 As shown, the grinding table 100 is a welded structure, the cylinder base 120 is located at the lower part of the grinding table 100, and is connected with the cylinder body of the cylinder 101, and the piston rod of the cylinder 101 is connected with the mandrel 102 of the guiding mechanism. The mandrel 102 of the guiding mechanism is connected with the connecting cylinder 104, the upper end of the connecting cylinder 104 is connected with the crossbeam 105, the two ends of the crossbeam 105 are connected with the vertically placed connecting screw 106, and the connecting screw 106 is fixed on the crossbeam 105 by two nuts, the connecting screw 106 can be Connect with the workpiece to be ground. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com