Machining tool, turn-milling equipment and turn-milling method of aero-engine swirler

A technology of aero-engine and cyclone, which is applied in the direction of metal processing equipment, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve problems such as large jump of processing cyclone, prolong service life, improve processing quality, The effect of reducing the magnitude of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

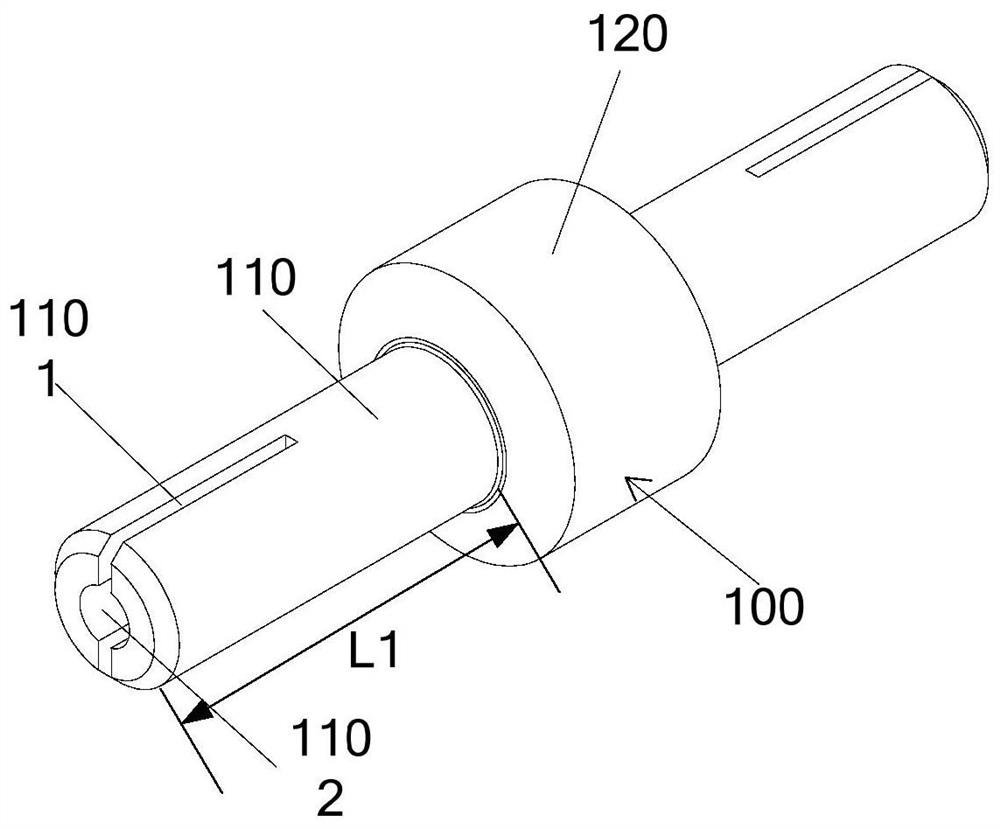

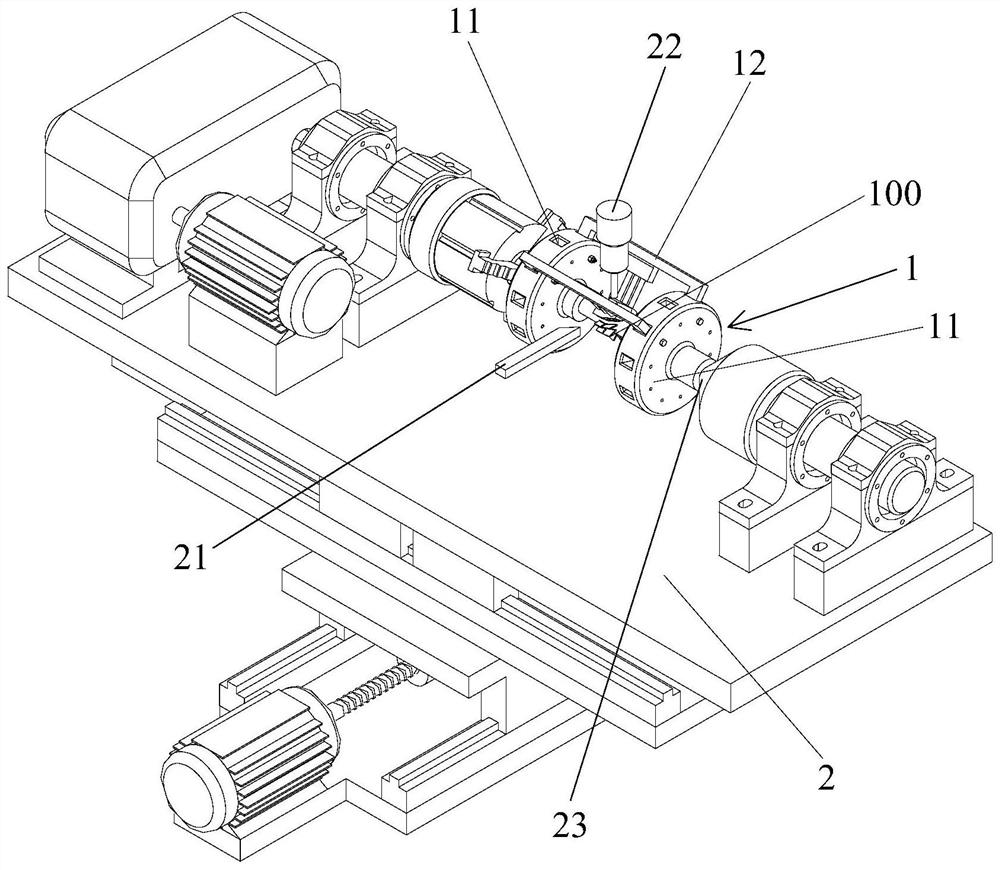

[0051] Such as image 3 , Figure 4 As shown, in order to solve the problem that the semi-finished product of the cyclone produces large jumps and vibrations during the milling process, the present invention provides a processing tool 1 for the cyclone of an aero-engine, which can hold the cyclone when processing the semi-finished product of the cyclone. The semi-finished cyclone, the processing tool 1 includes two flywheels 11 that can be fixedly connected to the two ends of the semi-finished cyclone 100 respectively, when the semi-finished cyclone 100 is processed, the semi-finished cyclone 100 and the two ends fixed on The two flywheels 11 form an integral part and are installed on the processing machine tool. The cyclone semi-finished product 100 and the two flywheels 11 can move and rotate synchronously under the drive of the processing machine tool. For example, the processing machine tool is a CNC machine tool 2 .

[0052] The invention sets two flywheels to clamp the ...

Embodiment approach 2

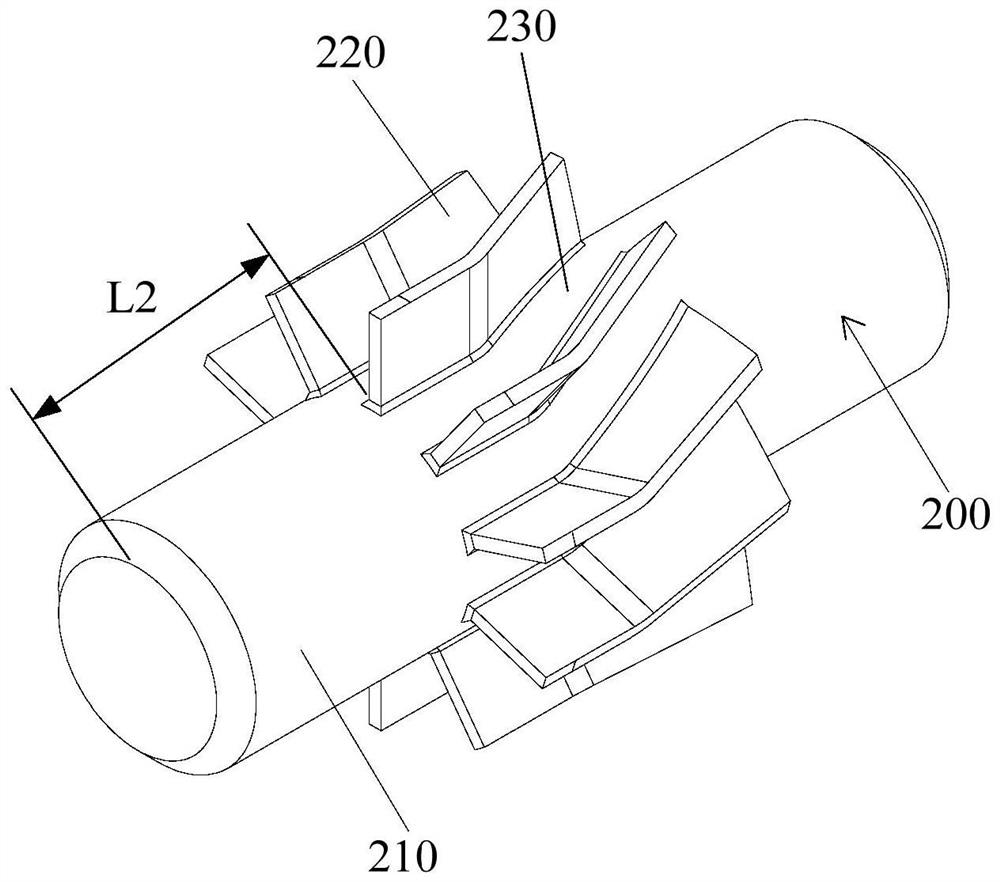

[0065] Such as image 3 As shown, the present invention also provides a turning and milling equipment of an aero-engine swirler, which is used to process the semi-finished swirler 100 into a finished swirler 200. The structures of the semi-finished swirler 100 and the finished swirler 200 are as follows As mentioned above, the turning and milling equipment includes a CNC machine tool 2 and a processing tool 1. The processing tool 1 in this embodiment has the same structure, working principle and beneficial effects as the first embodiment, so it will not be described in detail here; the CNC machine tool 2 has a lathe Knife 21, milling cutter 22, and two clamping ends 23 arranged at relative intervals, and two flywheels 11 are respectively fixedly connected to the two clamping ends 23, for example, the axle sleeve 111 of the flywheel 11 is detachably fixedly connected to the clamping ends 23 , in the state that the two ends of the first shaft part 110 of the semi-finished cyclon...

Embodiment approach 3

[0077] Such as Figure 13 As shown, the present invention also provides a turning-milling method of an aero-engine swirler, which adopts the turning-milling equipment of Embodiment 2 to process the swirler semi-finished product 100 into a swirler finished product 200, and the turning-milling method of the present invention includes the following step:

[0078] Step S10: Prepare the semi-finished cyclone 100. The specific preparation method of the semi-finished cyclone 100 is the prior art, so it will not be described in detail;

[0079] Step S20: Fixing the two ends of the first shaft part 110 of the cyclone semi-finished product 100 to the two flywheels 11 respectively;

[0080] Step S30: install the integral part composed of the semi-finished cyclone 100 and the two flywheels 11 between the two clamping ends 23 of the CNC machine tool 2;

[0081] Step S40: using the milling cutter 22 of the CNC machine tool 2 to mill a swirl groove 230 on the processing part 120 of the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com