Bilateral bidirectional slip form milling device

A sliding form and milling technology, which is applied in the field of double-sided two-way sliding form milling and planing devices, can solve the problems of inconvenient turning of the mold traction equipment of the sliding form machine, single function of the sliding form machine, and inconvenient supply of concrete, etc., to achieve improved groove milling The effect of planing construction efficiency, avoiding the inconvenience of turning around, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

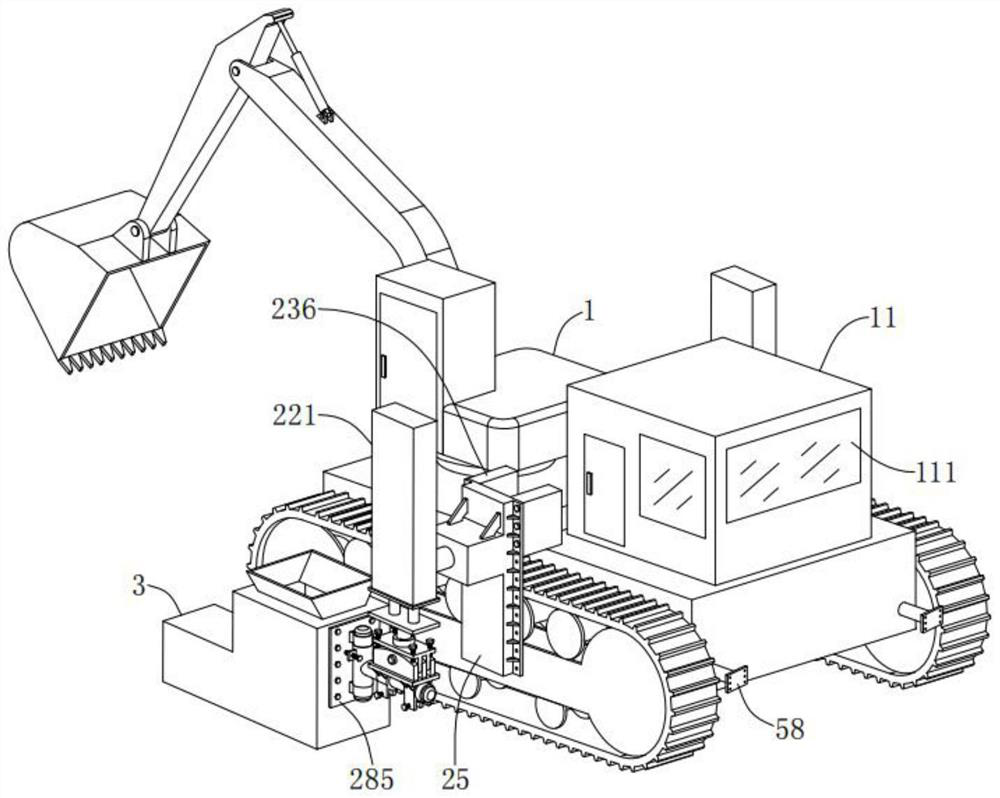

[0044] Such as Figure 1-Figure 10 As shown, a double-sided two-way sliding form milling device includes a traction device 1, a tractor and a slipform machine mold 3 or a milling machine 4 installed on the tractor. The upper end of the traction device 1 is provided with a slipform milling Operating room 11, slipform milling operating room 11 is located at the cab rear of traction equipment 1, it should be noted that traction equipment 1 of the present invention can be excavator, automobile or other self-propelled vehicle equipment, in this embodiment Adopt excavator, do not influence protection scope of the present invention. Specifically, transparent windows 111 are provided on the four side walls of the slipform milling operation room 11 in this embodiment, so that the operator can easily know the working status of the slipform machine mold 3 or the milling machine 4 for easy operation.

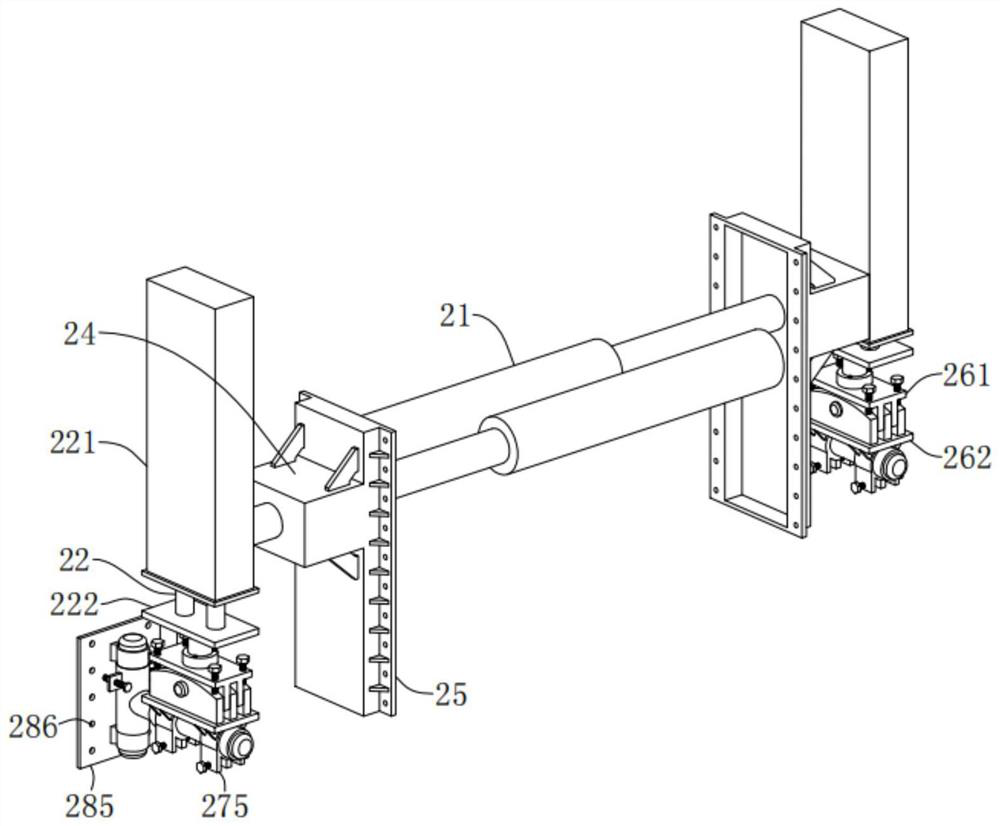

[0045] The tractor includes a horizontal hydraulic cylinder 21 for adjusting the dista...

Embodiment 2

[0056] As a further preferred implementation mode of the present invention, the same features of this embodiment and embodiment 1 will not be repeated, and the different features are:

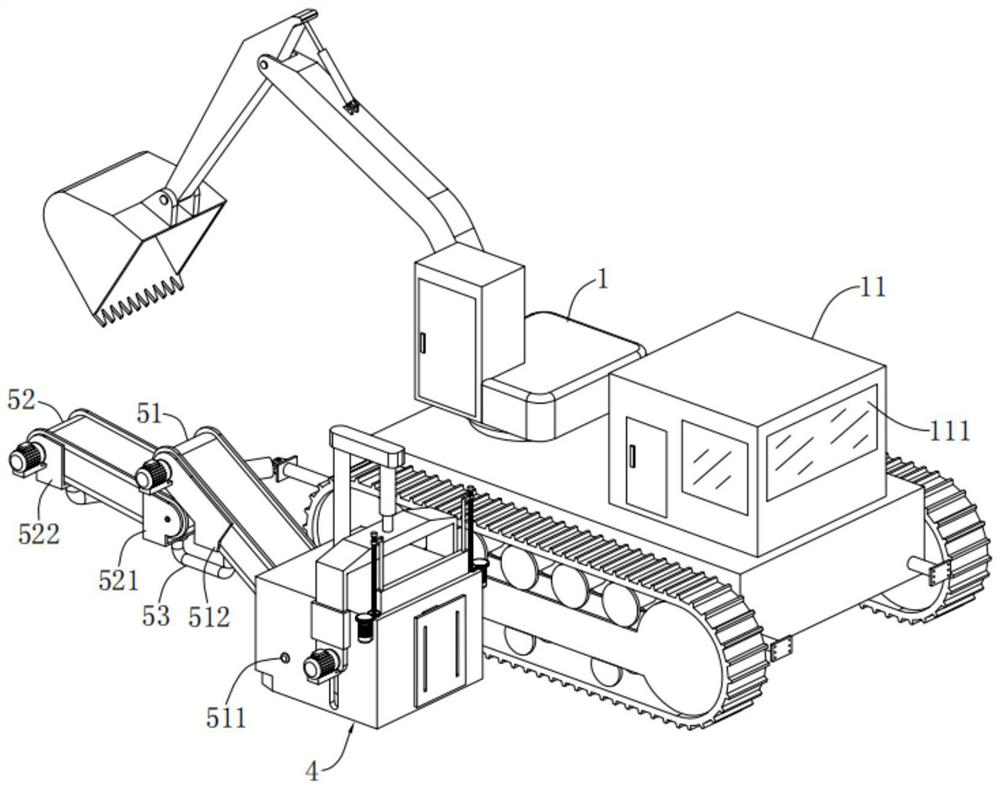

[0057] refer to figure 2 , Figure 8 , Figure 9 , the slipform milling device in this embodiment also includes an aggregate conveying device, the aggregate conveying device includes a first conveyor 51 and a second conveyor 52, and the driving motors of the first conveyor 51 and the second conveyor 52 are both Connected with the control module, the first conveyor 51 is arranged obliquely, its feeding end extends into the inside of the housing 41 of the milling machine 4 and is connected with the housing 41 through the first connecting shaft 511, and the feeding end of the second conveyor 52 Be positioned at the below of the discharge end of the first conveyor 51; The discharge end of the first conveyor 51 is provided with the first support 512, the loading end of the second conveyor 52 is p...

Embodiment 3

[0059] As a further preferred embodiment of the present invention, the same features of this embodiment and embodiment 2 will not be repeated, and the different features are:

[0060] refer to Figure 8-Figure 9 In this embodiment, a height-adjustable retaining plate 44 is vertically arranged on the inner side of the housing 41 away from the end of the first conveyor 51 , and the width of the retaining plate 44 is slightly smaller than the length of the milling rotor 42 .

[0061] Specifically, the upper end of the soil retaining plate 44 in this embodiment penetrates the top of the housing 41 and is slidably fitted with it. Both sides are provided with a servo motor 442 for driving the screw 441 to rotate around the axis. The servo motor 442 is connected to the control module. The screw rod is provided with a sleeve 443 threaded with it, and a transverse connecting rod 444 is provided on the outside of the sleeve 443 , the transverse connecting rod 444 is fixed to the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com