Drilling device for treatment of fire area and subsidence area of steeply inclined coal seam

A technology of drilling device and collapse area, which is applied to supporting devices, drilling equipment and methods, drilling equipment, etc., can solve the problems of dust disposal, damage to the environment, etc., and achieve the effect of simple structure, avoiding impact on the environment, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

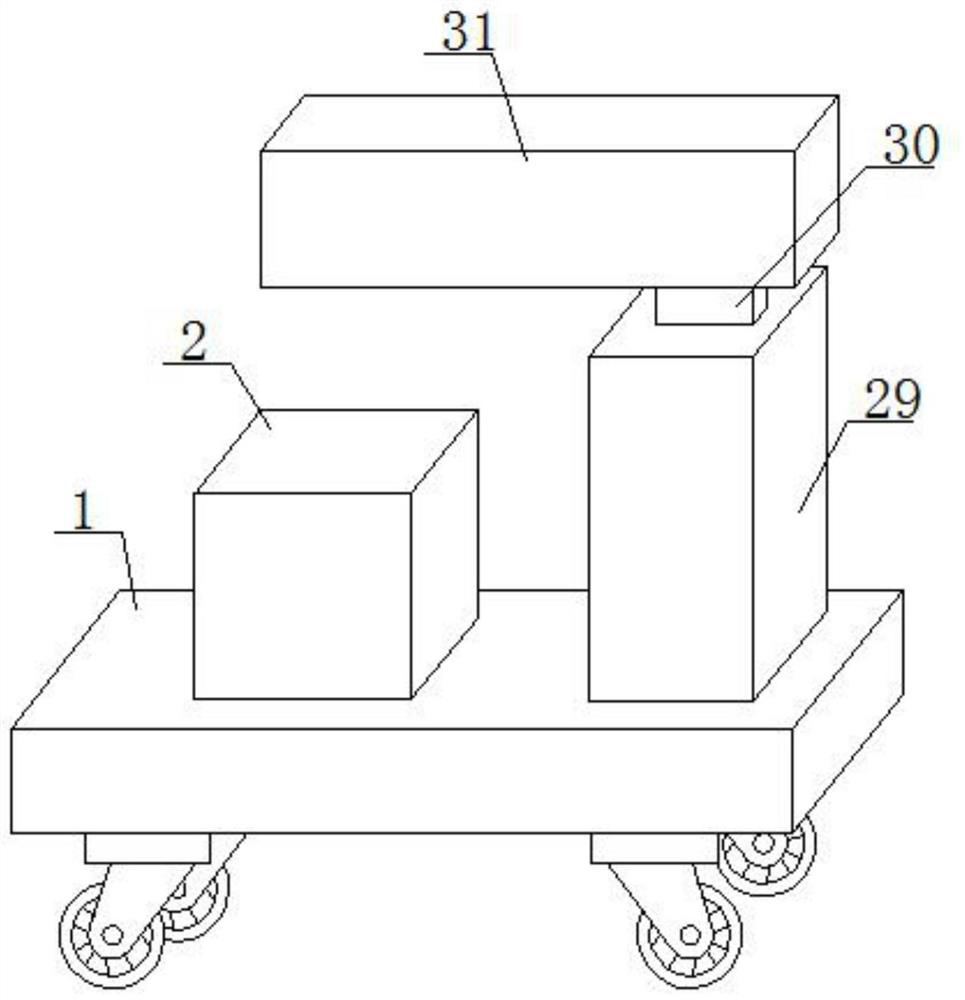

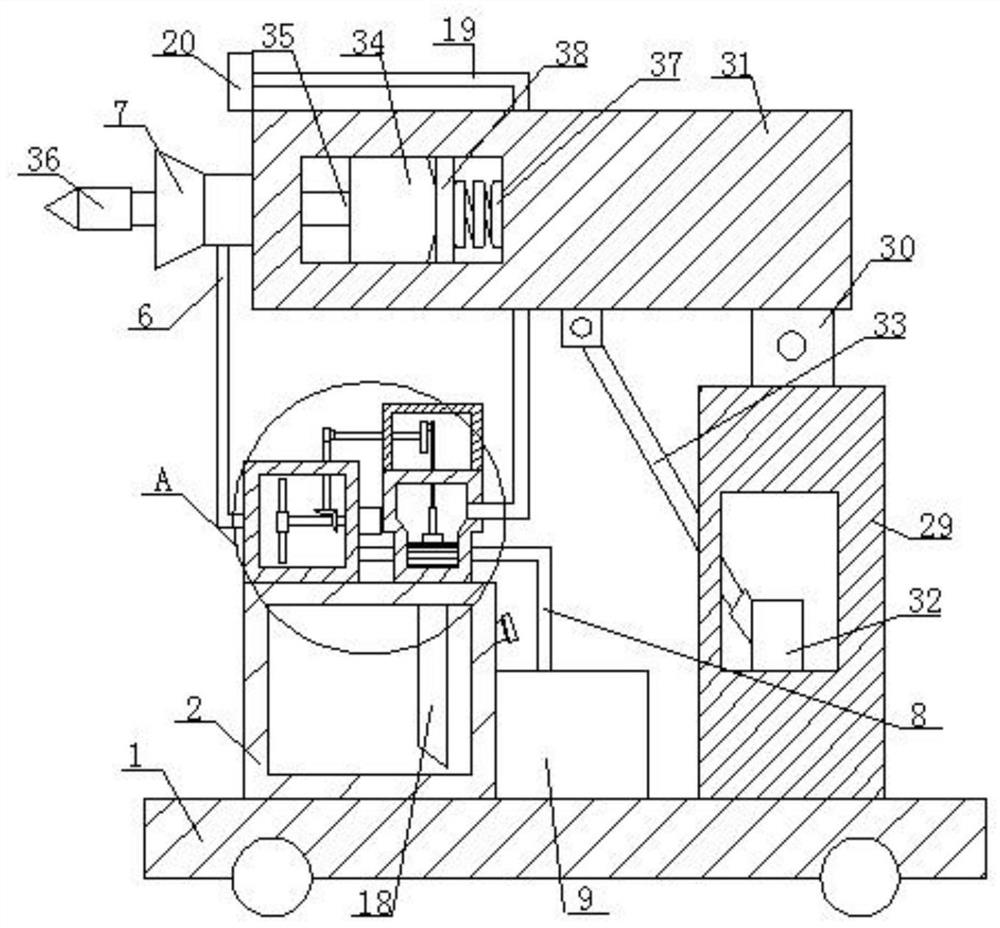

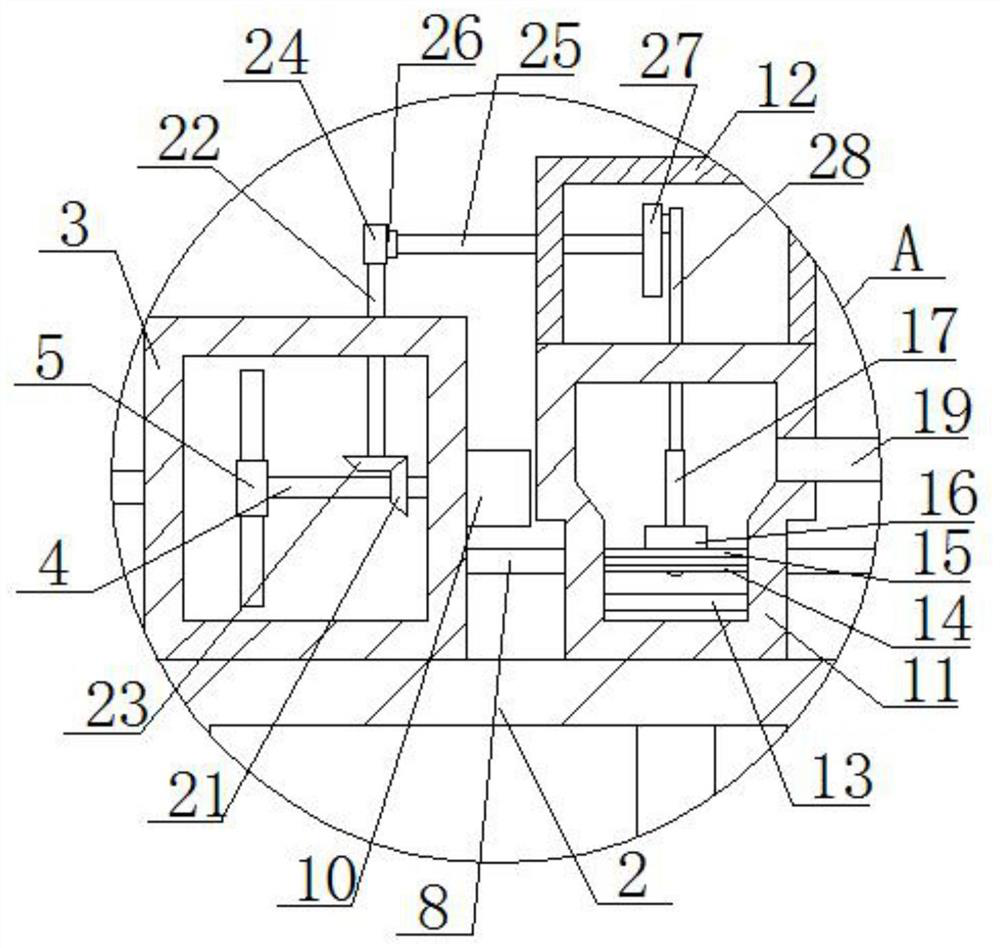

[0024] refer to Figure 1-5 , a drilling device for controlling the subsidence area of a sharply inclined coal seam fire zone, comprising a base 1, a water tank 2 is fixedly installed on the top of the base 1, a dust collection box 3 is fixedly installed on the top of the water tank 2, and a suction box 3 is installed inside the dust collection box 3. Dust mechanism, the dust collection mechanism includes the fan blade rotating rod 4 and the dust suction fan blade 5, the fan blade rotating rod 4 is connected with the dust collection box 3 in rotation, the dust suction fan blade 5 is fixedly connected with one end of the fan blade rotating rod 4, and the dust suction One side of the box 3 is connected with a dust suction pipe 6, one end of the dust suction pipe 6 is connected with a dust collection cover 7, the other side of the dust collection box 3 is connected with a dust collection pipe 8, and the top of the base 1 is fixedly installed with a collection box 9 , the collec...

Embodiment 2

[0032] refer to Figure 1-5 , a drilling device for controlling the subsidence area of a steeply inclined coal seam fire area, comprising a base 1, a water tank 2 is welded and installed on the top of the base 1, a dust collection box 3 is welded and installed on the top of the water tank 2, and a suction box 3 is installed inside the dust collection box 3 Dust mechanism, the dust collection mechanism includes the fan blade rotating rod 4 and the dust suction fan blade 5, the fan blade rotating rod 4 is connected to the dust collection box 3 in rotation, the dust suction fan blade 5 is welded to one end of the fan blade rotating rod 4, and the dust suction One side of the box 3 is connected with a dust suction pipe 6, one end of the dust suction pipe 6 is connected with a dust collection cover 7, the other side of the dust collection box 3 is connected with a dust collection pipe 8, and the top of the base 1 is welded with a collection box 9 , the collection box 9 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com