Zoom lens structure capable of ensuring optical axis consistency

A zoom lens, consistent technology, applied in optics, optical components, installation, etc., can solve problems such as large errors, optical axis offset, and image quality degradation, and achieve the effects of reducing errors, improving precision, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

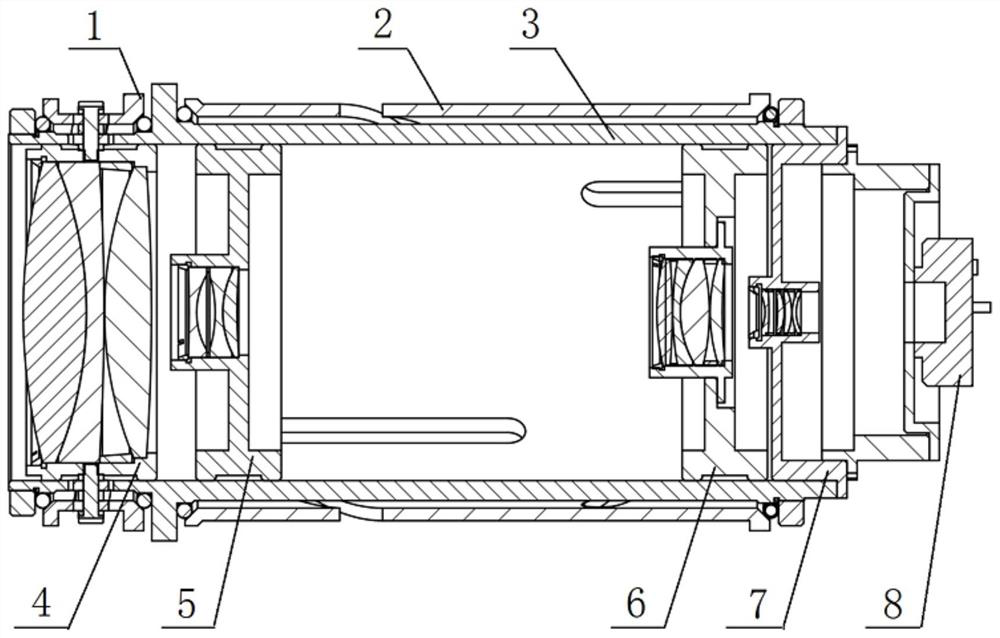

[0029] Such as figure 1 As shown, a zoom lens structure that ensures optical axis consistency includes a front cam 1, a rear cam 2, a lens barrel 3, a front group 4, a zoom group 5, a compensation group 6, and a rear group 7. The lens barrel 3 is slidably matched with the guide surfaces of the front group 4, the zoom group 5, the compensation group 6, and the rear group 7.

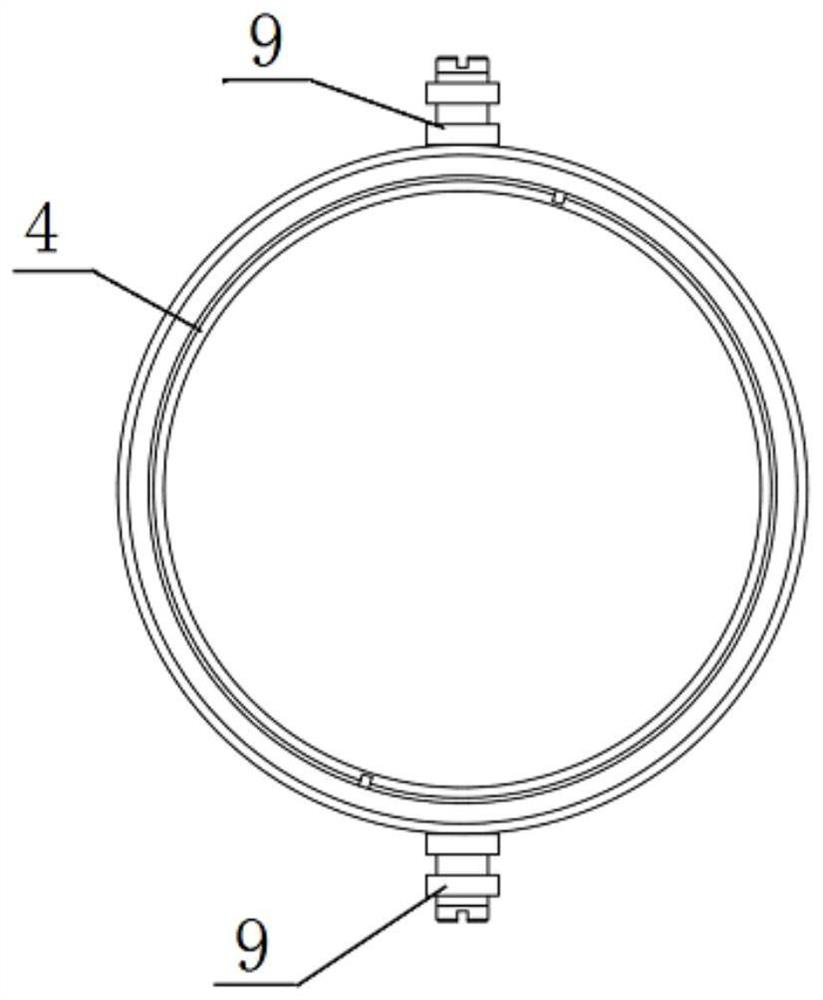

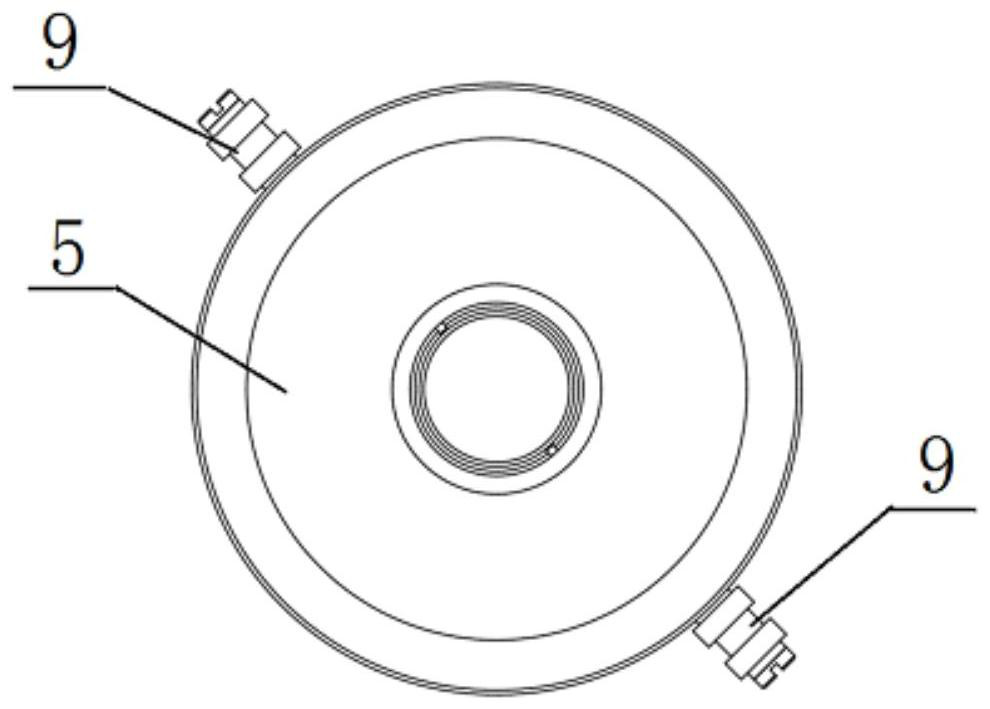

[0030] Such as figure 2 As shown, two guide nails 9 are fixed on the same diameter on the outer circumferential surface of the front group 4; the front group 4 is installed inside the lens barrel 3, and the front cam 1 is set outside the lens barrel 3; Figure 5 As shown, the front cam 1 has a set of focusing curve grooves for controlling the focus of the front group 4; the position of the lens barrel 3 corresponding to the focus curve grooves is also provided with a through guide g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com