In-plant logistics distribution method oriented to cost optimization

A logistics distribution and cost technology, applied in the field of logistics, can solve problems such as poor customer service experience, users' subjective payment order cannot reflect objective needs, and single commodity types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

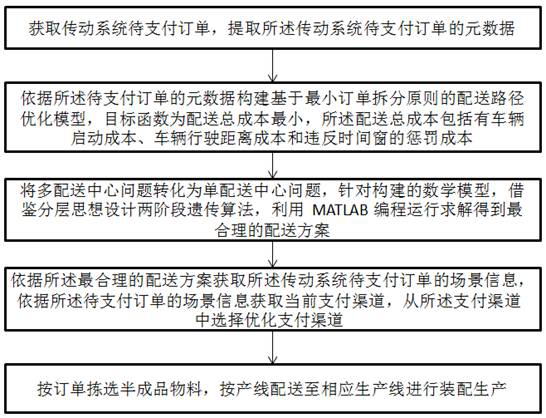

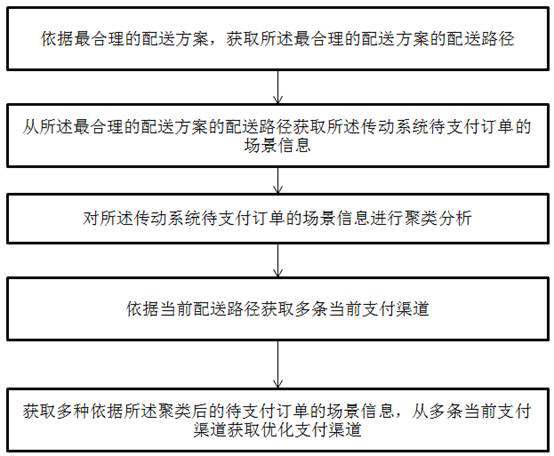

[0034] Illustrative embodiments of the present application include, but are not limited to, a method for cost-optimized in-plant logistics distribution.

[0035] It will be appreciated that, as used herein, the terms; module; unit; may refer to or include an Application Specific Integrated Circuit (ASIC), an electronic circuit, a processor (shared, dedicated, or group ) and / or memories, combinational logic circuits, and / or other suitable hardware components that provide the described functionality, or may be part of these hardware components.

[0036] It can be understood that, in each embodiment of the present application, the processor may be a microprocessor, a digital signal processor, a microcontroller, etc., and / or any combination thereof. According to another aspect, the processor may be a single-core processor, a multi-core processor, etc., and / or any combination thereof.

[0037] It can be understood that a cost-optimized in-factory logistics distribution method prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com