Suction type anesthesia machine for general anesthesia

A general anesthesia and anesthesia machine technology, applied in the field of anesthesia machines, can solve the problem of slow exhaust gas discharge, and achieve the effect of reducing the amount of exhaust gas, reducing the content of exhaust gas, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

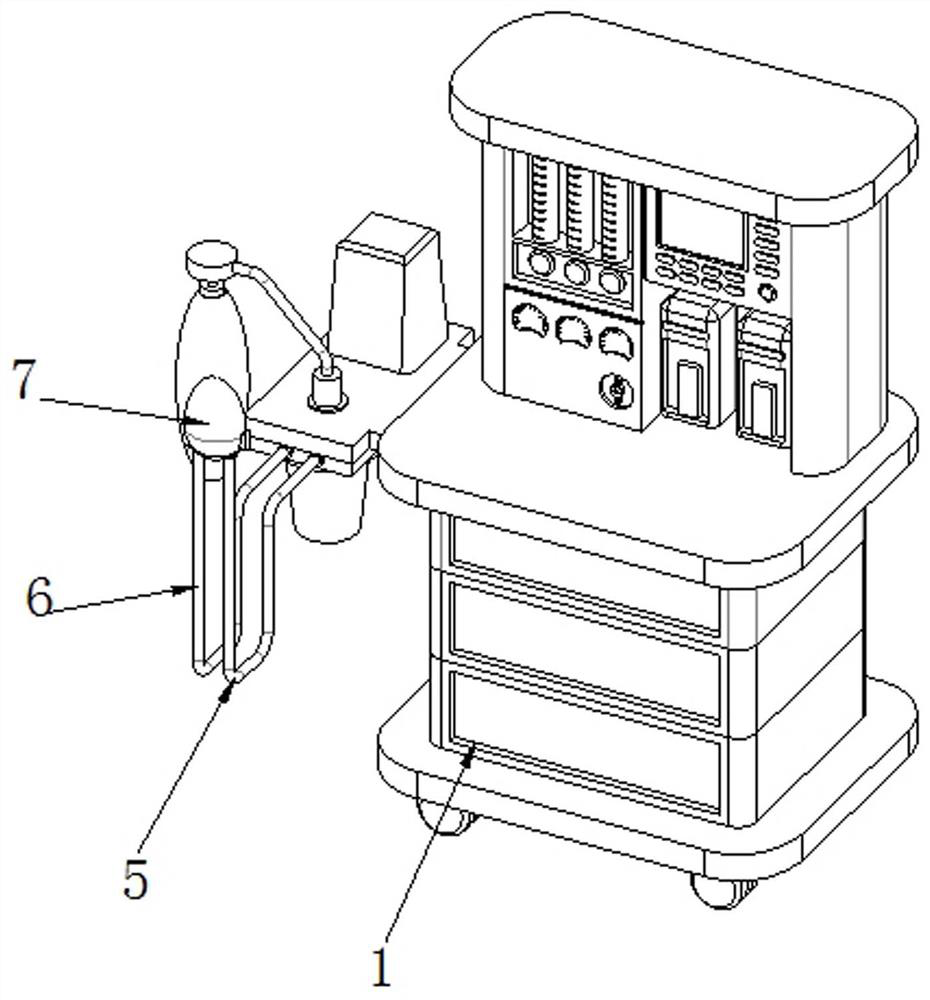

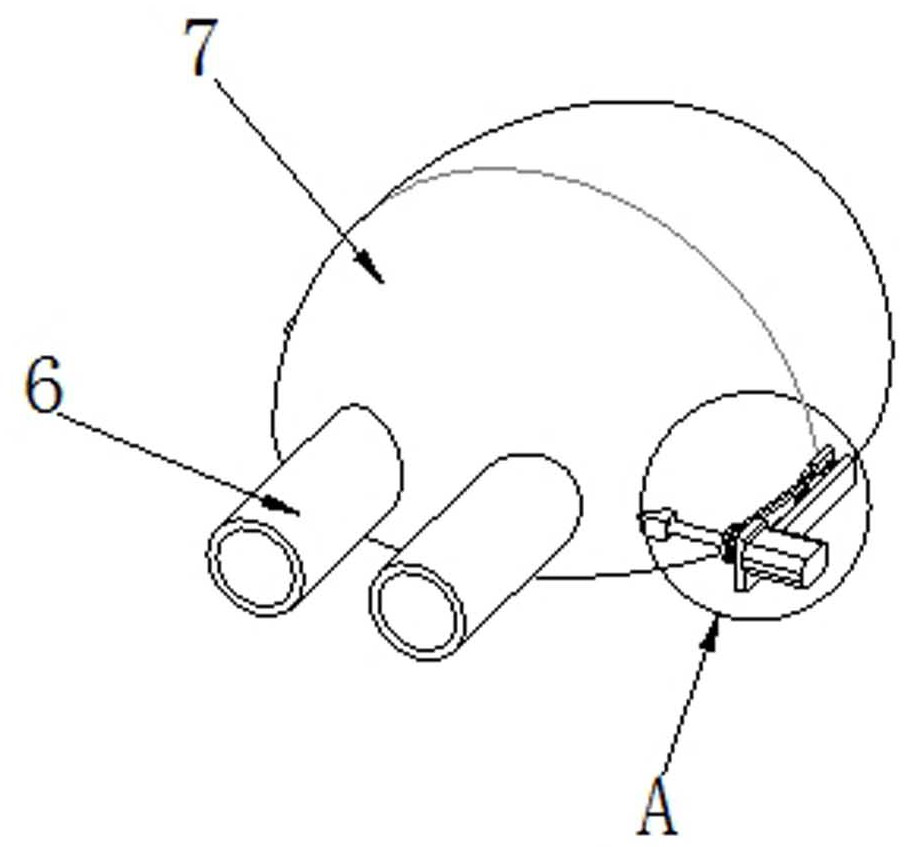

[0038] see Figure 1-6 As shown, an inhalation anesthesia machine for general anesthesia includes an anesthesia machine body 1, an air intake pipe 5, an exhaust pipe 6 and a mask 7, an air intake pipe 5 is connected to one side of the upper surface of the anesthesia machine body 1, and an anesthesia machine body 1 The side of the upper surface close to the intake pipe 5 is connected with an exhaust pipe 6, and the end of the exhaust pipe 6 away from the anesthesia machine body 1 is connected with a mask 7;

[0039] When the inhalation anesthesia machine is working, the mask 7 is connected to the mouth and nose of the patient, and the inlet pipe 5 and the exhaust pipe 6 are connected with one-way valves, so that only the atomized anesthetic can be carried out at the inlet pipe 5 Considering the circulation at position 7 of the mask, the position at exhaust pipe 6 can only circulate the patient’s exhaled exhaust gas. When the patient is inhaling, the one-way valve at position 6 ...

Embodiment 2

[0044] see Figure 7-9 As shown, the inside wall of the mask 7 is provided with an antibacterial mechanism 3 near the position of the exhaust pipe 6. The antibacterial mechanism 3 includes a driven shaft 31. The position corresponding to the intake pipe 5 and the exhaust pipe 6 on the side is connected with the antibacterial slave gear 36, and the inner wall of the intake pipe 5 and the exhaust pipe 6 is provided with a chute 35 near the position of the driven rotating shaft 31, and the intake pipe 5 and the exhaust pipe 6. A supporting frame 32 is connected to the inner side wall close to the chute 35, and a rotating frame 310 is connected to the middle position of the outer side wall of the supporting frame 32 through a connecting shaft 37. The end of the connecting shaft 37 away from the supporting frame 32 is connected to an antibacterial driving gear 33. , the antibacterial driving gear 33 and the antibacterial secondary gear 36 are perpendicular to each other and are fit...

Embodiment 3

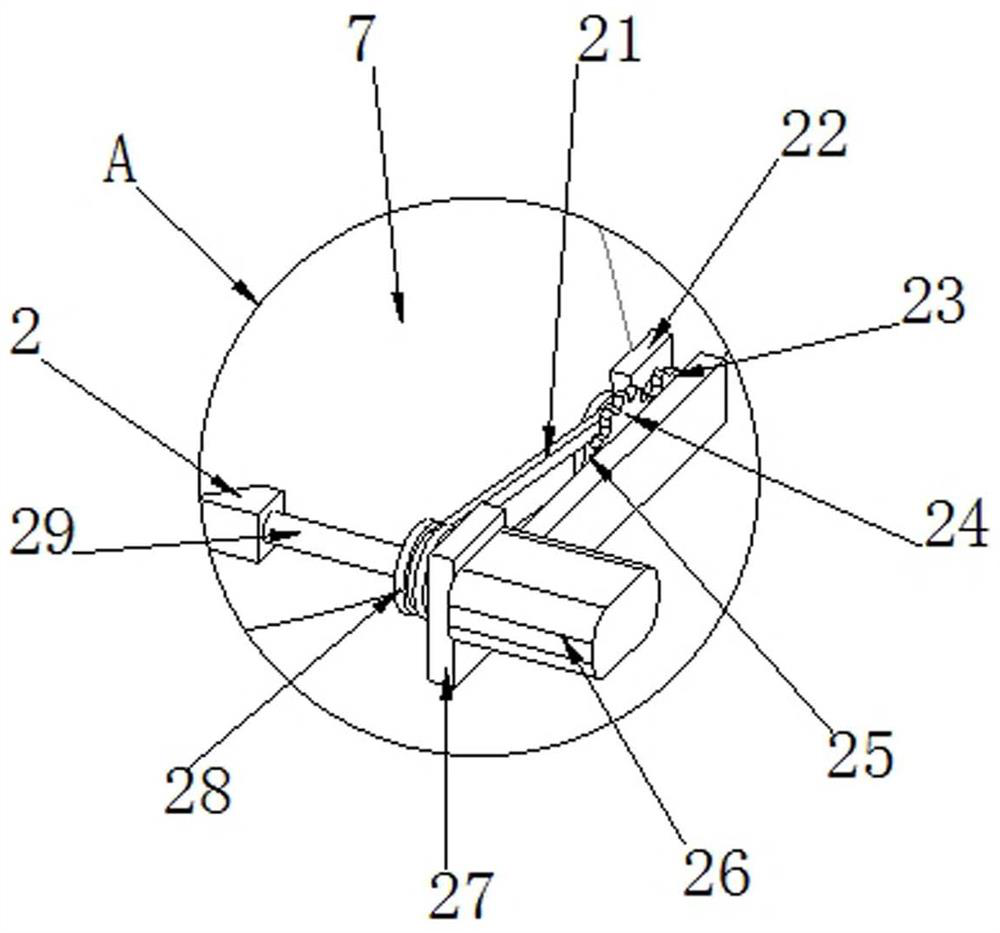

[0048] see Figure 10As shown, the outer wall of the face mask 7 is provided with an exhaust mechanism 4 near the position of the intake pipe 5, and the exhaust mechanism 4 includes an exhaust runner 49, and the outer wall of the drive shaft 29 is connected with an exhaust outlet corresponding to the exhaust runner 49. The main runner 41, the exhaust main runner 41 is connected with the exhaust slave runner 49 through the transmission belt 21, and the outer wall of the mask 7 is connected with a reciprocating screw 44 through the exhaust support seat 48 corresponding to the exhaust slave runner 49, The outer wall of the reciprocating lead screw 44 is slidably connected with a reciprocating plate 43, and the two sides of the outer wall of the reciprocating plate 43 are connected with telescopic hoses 46. Valve, so that the flexible hose 46 can only inhale from the end of the exhaust pipe 6 close to the mask 7, and can only exhaust from the end of the exhaust pipe 6 away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com