Outer span lug filter plate automatic cleaning device and corresponding automatic plate pulling and sweeping mechanism

An automatic cleaning and filter plate technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of easy accumulation of scattered filter cakes, unsafe, low efficiency of scattered cakes, etc., and achieve the improvement of fully automatic performance and performance Reliable, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

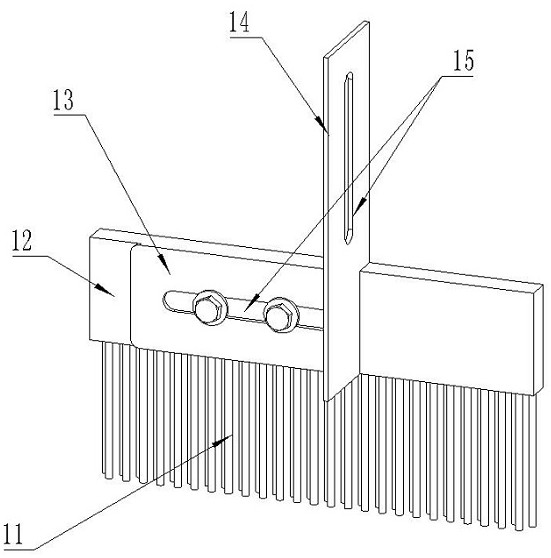

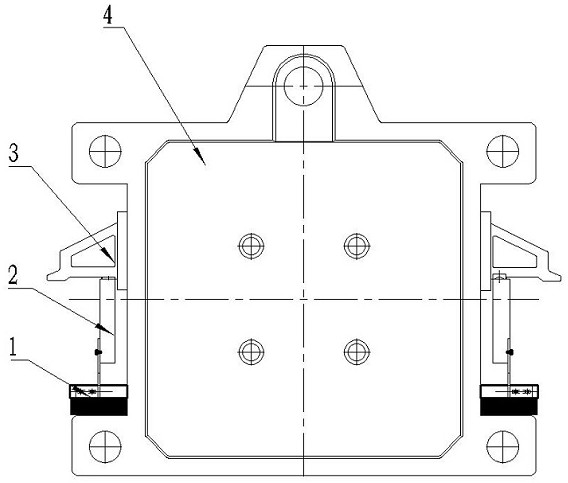

[0022] An automatic cleaning device 1 (hereinafter referred to as: automatic plate sweeping device) for the outer cross-ear filter plate, the main point of the innovative overall implementation is that an automatic plate sweeping device 1 is added on the basis of the automatic plate pulling, including sweeping plate brush 11 , three sets of automatic plate sweeping devices 1 are cleverly installed on the main beams 2 on both sides of the frame, and the sweeping plate brushes 11 can be fine-tuned horizontally and vertically to correspond to the lower cross ears of the filter plate 4. When the filter plate 4 is opened and When pressed, the sweeping brush 11 and the filter plate 4 move in a relatively straight line to automatically clean the loose cakes stored on the upper cross ear of the filter plate 4.

[0023] The specific embodiment is: the automatic plate sweeping device 1 is mainly composed of a sweeping plate brush (brush wire) 11, a planting brush plate 12, a brush connec...

Embodiment 2

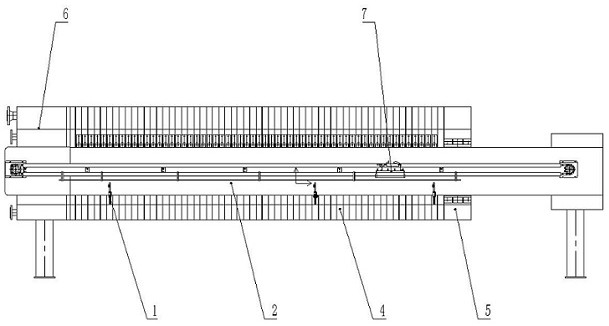

[0031]An automatic plate-drawing and sweeping mechanism, that is, the filter plate is automatically pulled apart and the automatic plate-sweeping mechanism is used, using the automatic cleaning device 1 for the outer-span filter plate provided by the present invention; The trolley and its guide rail, chain transmission device, and automatic plate sweeping device (the present invention) 1. It is composed of sensors; it has the characteristics of automatic plate pulling and automatic plate sweeping; it is used for the corresponding automatic filter press to automatically clean the filter plate 4. cake. The automatic filter press is mainly composed of a double-beam frame, a hydraulic pressing mechanism, a filtering mechanism, a plate-drawing and sweeping mechanism, a cloth washing mechanism, a liquid-contacting plate-turning mechanism, and a PLC program control system; The plate 4 is supported on the guide rails of the double main beam 2 of the rack.

[0032] The general assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com