Critical extraction process method for deep processing of tea oil and equipment thereof

A critical extraction and deep processing technology, applied in chemical instruments and methods, cleaning methods and utensils, edible oil/fat, etc., can solve the problems of inability to further improve the extraction quality, single stirring method, etc., to improve the extraction time and extraction rate, Good cleaning effect, speed up the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

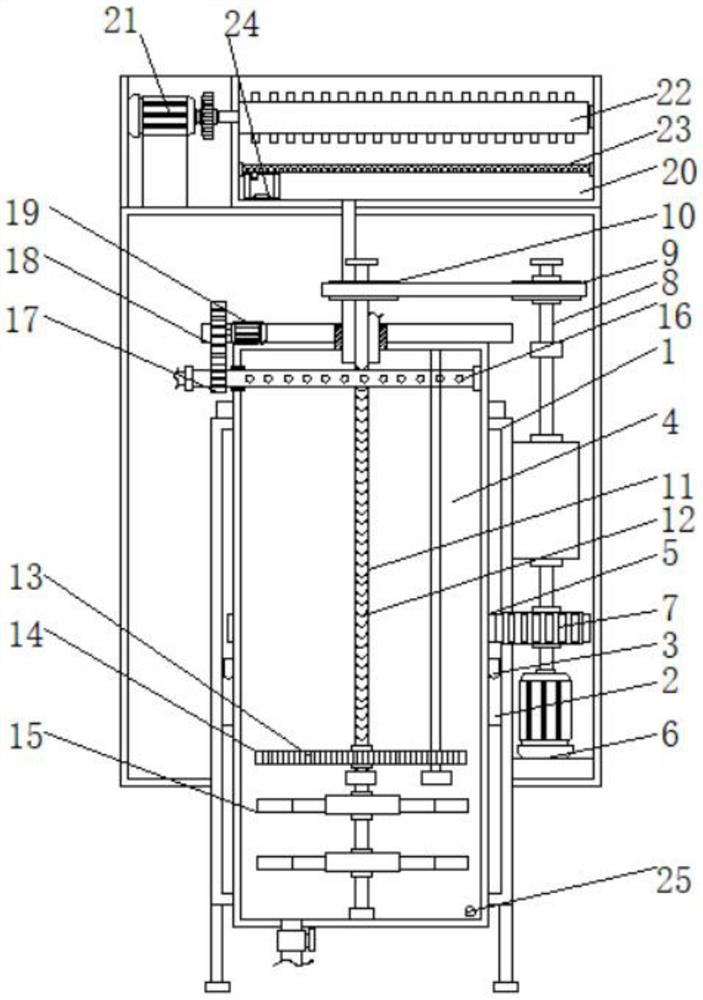

[0034]The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0035] The embodiments of the present invention will be described below according to the overall structure of the present invention.

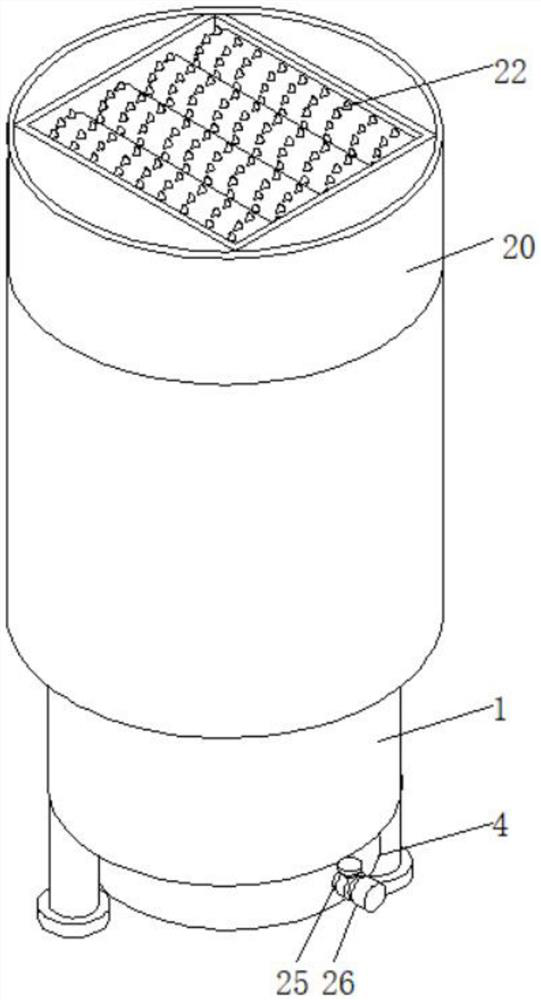

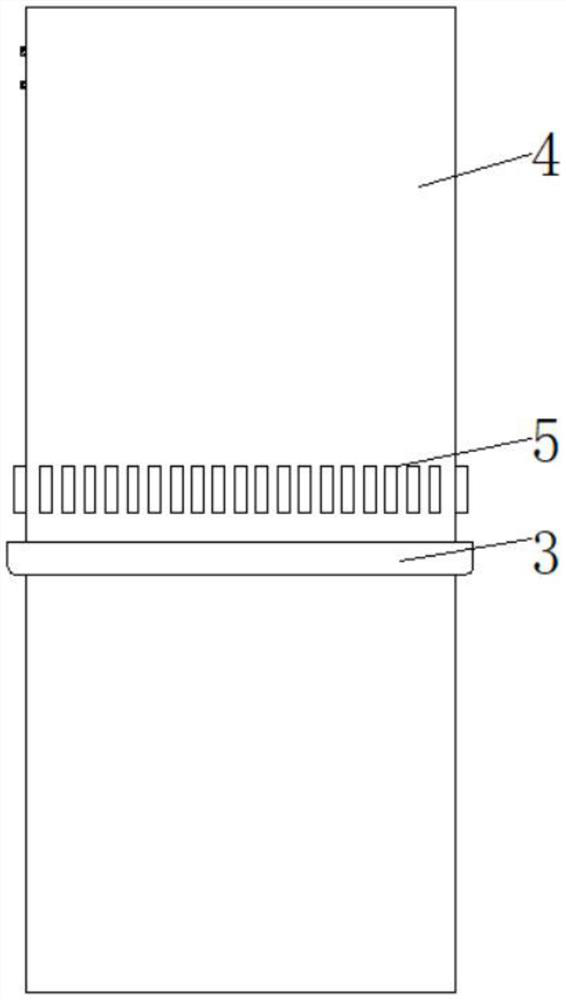

[0036] see Figure 1-7 , a critical extraction process and equipment for deep processing of camellia oil, comprising an extraction kettle 1, the interior of the extraction kettle 1 is connected to the outer side of the rotating cylinder 4 with a bracket 2, and the inside of the bracket 2 is provided with brackets, the brackets There is a rotating block 3 inside, and the rotating block 3 is matched with the bracket. The rotating block 3 is connected to the supporting bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com