Vehicle-mounted grassland cow dung picking and crushing integrated device

A picking and crushing, vehicle-mounted technology, applied in cleaning methods, construction, grain processing, etc., can solve the problems of high input cost, low cow dung collection efficiency, and low operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

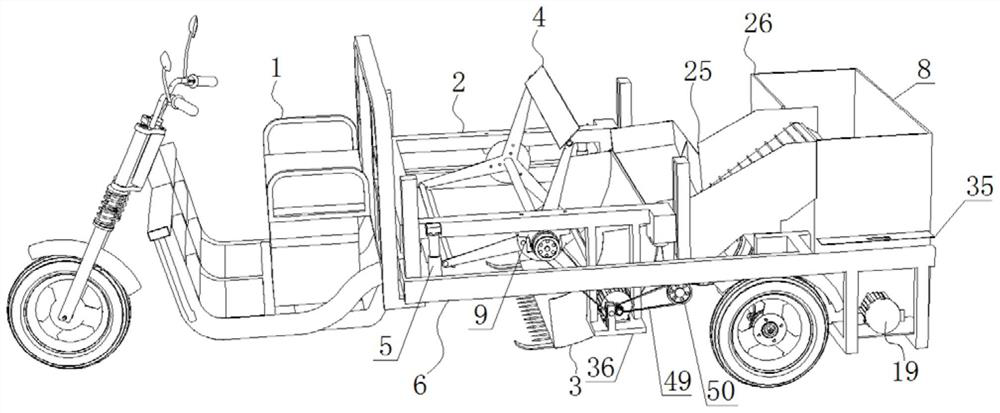

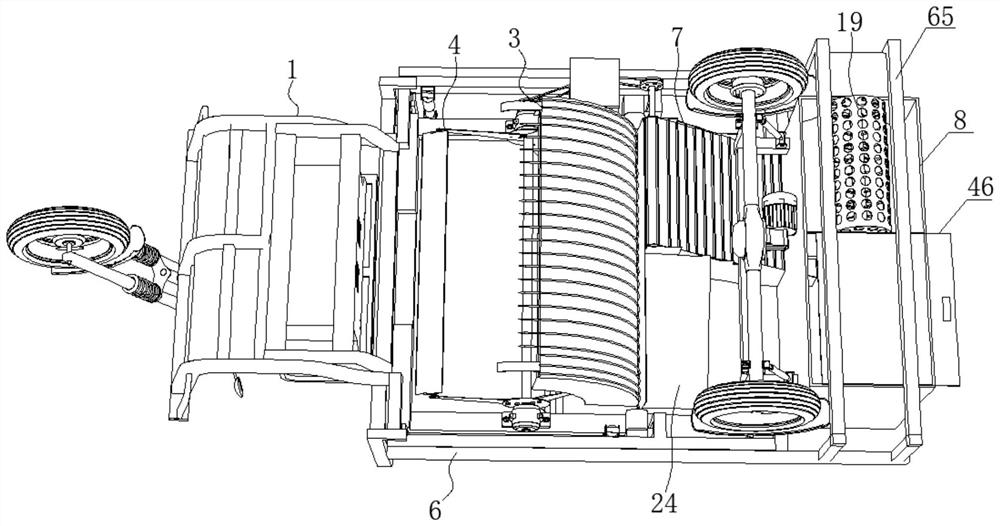

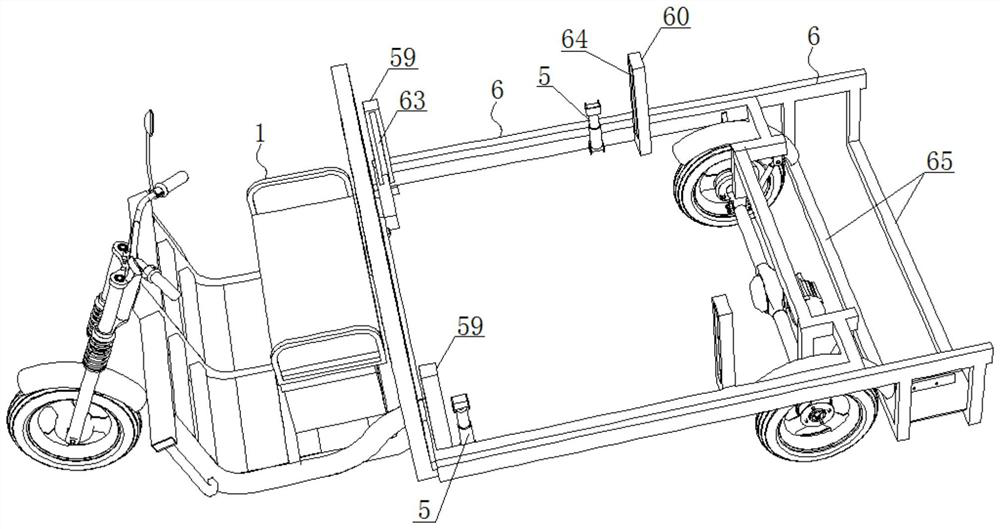

[0037] Such as Figure 1 to Figure 16 As shown, the present invention provides a vehicle-mounted grassland cow dung picking and crushing integrated device, including a car body 1, a support frame 2, a collection mechanism 3, a material shifting mechanism 4, a storage material crushing mechanism 26 and an aggregate lifting mechanism 25; The vehicle frame 6 of the vehicle body 1 is a frame structure;

[0038] The support frame 2 is horizontally assembled on the left part of the inner space of the vehicle frame 6, and a motor support 36 is fixedly connected to the bottom of the right part of the rear side beam. One side of the output shaft of the motor A37 is fixedly connected with a pair of vertical plates 40; the output shaft of the drive motor A37 is equipped with a driving pulley 38 and a driving gear 39 at intervals; The output shaft of the driving motor A37 is parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com