Plastic shell conveying batten and shell buckling machine

A technology of conveying strips and conveying chains, which is applied in the field of plastic casing conveying slats and shell buckling machines, which can solve the problems of poor fixing effect of plastic casings, and achieve the effects of structural improvement, strong practicability, and structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

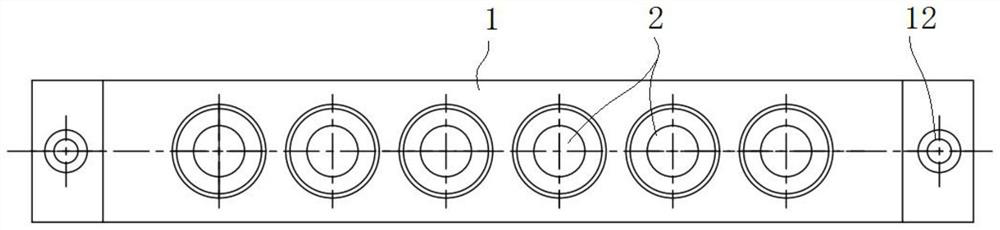

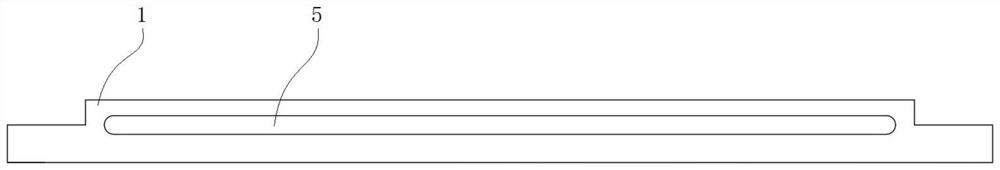

[0051] This embodiment provides a molded case conveying slat 100 , which includes a slat body 1 and a reinforcing rubber strip 4 , and a plurality of stepped holes 2 are opened on the slat body 1 , and any one of the stepped holes 2 runs through the thickness direction of the slat body 1 set, and the large hole 21 of any step hole 2 is used to load the plastic case 7, and the small hole 23 of any step hole 2 is used to support the plastic case 7; the inner wall of the large hole 21 of any step hole 2 is provided with a concave Groove 3; the reinforcing rubber strip 4 is embedded in the groove 3 and matches with the outer surface of the plastic case 7 to clamp and fix the plastic case 7 to prevent the plastic case 7 from rotating freely. The plastic case 7 is an existing pill loading structure, and is in a standard spherical shape as a whole. It includes a lower plastic case 71 and an upper plastic case 72 snapped to the lower plastic case 71 .

[0052] In this embodiment, the ...

Embodiment 2

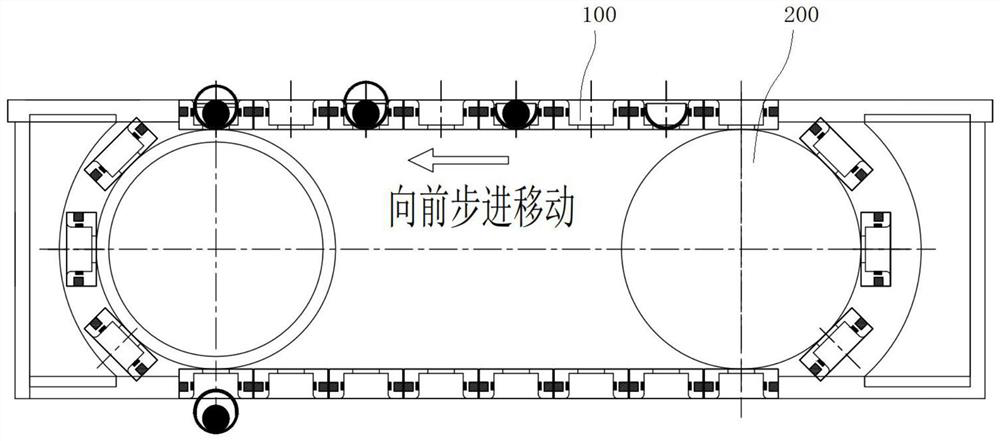

[0061] Such as figure 1 As shown, the present embodiment also proposes a shell buckle machine, which includes a conveying chain 200 and several plastic case conveying slats 100 as described in Embodiment 1; that is, figure 1 Shown in the "forward stepping movement" direction) are installed on the conveyor chain 200 in turn. Both ends of the strip body 1 of any molded case conveying strip 100 are provided with counterbore holes 12, which can be fixed with the conveying chain 200 through bolts and other connecting structures.

[0062] Shell buckling machine is a relatively mature technology. Except for the molded shell conveying slat 100, the rest of the structure basically adopts the existing technology, including the lower molded shell 71 insertion component, the pill insertion component, and the upper and lower molded shell compression components. And the power drive mechanism of the conveyor chain 200, etc., wherein the conveyor chain 200 can also be replaced by an outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com