Locomotive framework pull rod seat deformation measurement platform and method based on machine vision

A machine vision and measurement platform technology, applied in measurement devices, railway vehicle testing, instruments, etc., can solve the problems of long detection time, complex detection process, rework affecting construction period, etc., and achieve the effect of high measurement efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

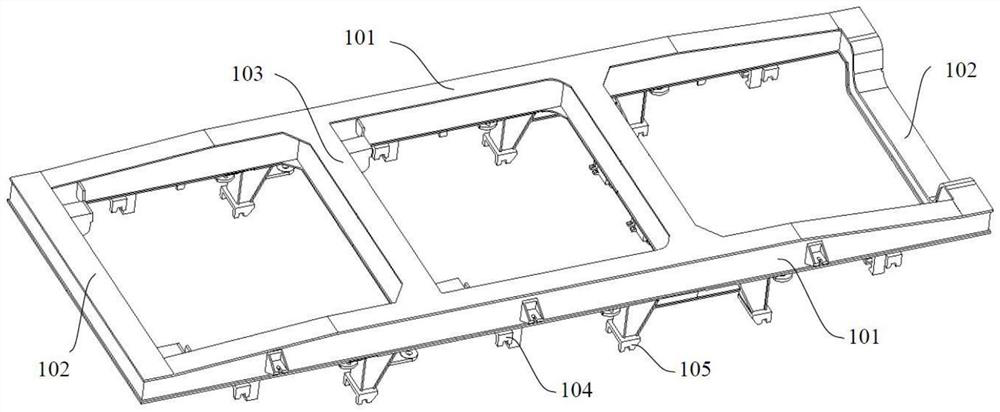

[0030] Such as figure 1 As shown, the locomotive frame 1 is mainly composed of two symmetrical side beams 101, two end beams 102, two beams 103, three sets of upper tensile rod 104, and pullip holder 105.

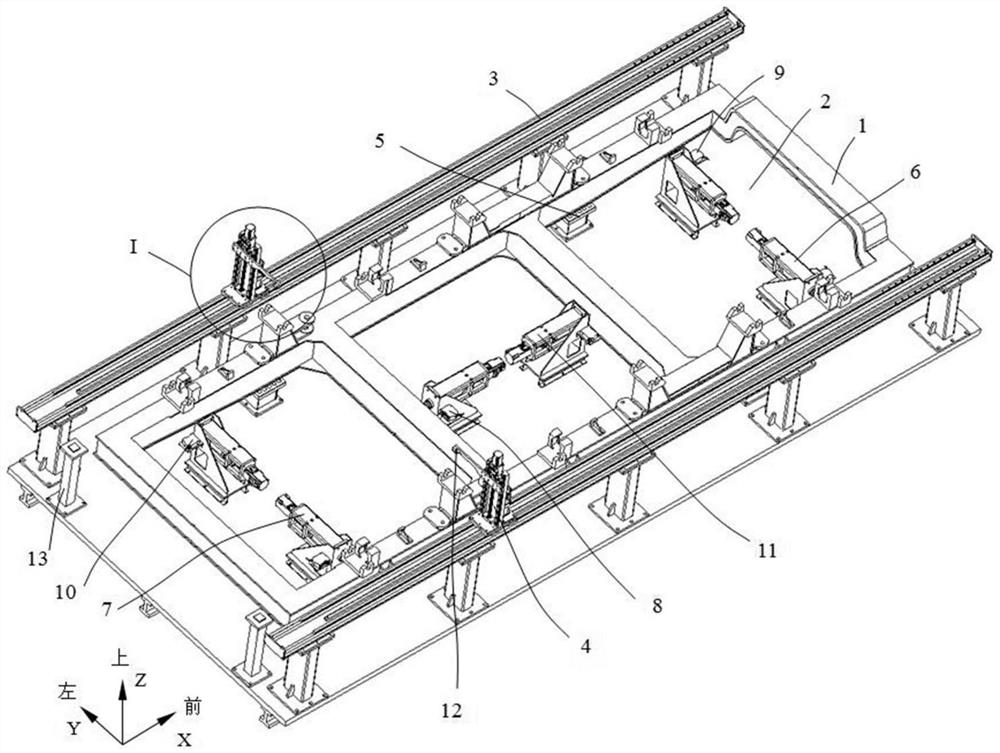

[0031] A machine-based locomotive frame trolley seat shape variable measurement platform, including a pedestal; a plurality of universal support hoses for supporting the locomotive frame; mounted on the base for adjusting the locomotive frame on the base Several adjusted devices of the relative position, each mounting device is attached to each regulating device; a calibration plate mounted on the base, mounted on the base for detecting a rod seat on the locomotive framework The machine vision device includes a first slider assembly mounted on a base, a second slider assembly on the first slice assembly, and a visual sensor is mounted on the second slider assembly.

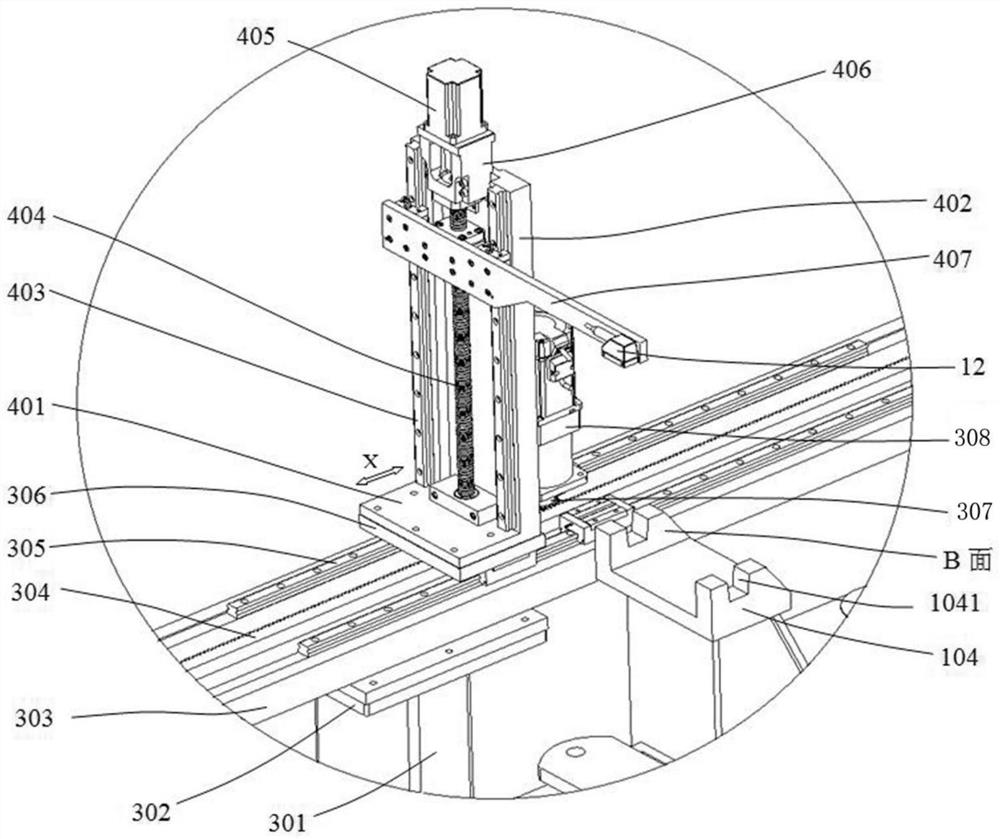

[0032] Such as Figure 2 ~ 8 As shown, a set of first slide assemblies 3 along X-direction arrangement is fixedly...

Embodiment 2

[0061] Based on the embodiment, a machine-visual locomotive frame tributylus seat shape variable measuring platform is provided, and this embodiment provides a method of changing the mounting rod seat shape based on a machine vision.

[0062] The method includes: a locomotive frame to a universal support seat to be detected; start the correction device according to the detection result of the ranging apparatus, adjust the locomotive frame; start the visual sensor and calibration; The sensor measured each trip course on the regular locomotive frame to obtain measurement data; the measurement data was processed, and the deformation amount of the locomotive frame and the axis deviation were calculated.

[0063] During the operation of the locomotive, the locomotive frame rod holder is often deformed due to the effects of various force. During the re-manufacturing process of the locomotive, the deformation of the tensile base must be detected, and the subsequent deviation calculation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com