Technology for producing phenylpyruvic acid by phenylalanine through enzymatic conversion

A technology of phenylpyruvate and amino acids, applied in the field of bioengineering, can solve the problems of low PAA yield, low enzyme activity of metabolic pathway, complex separation and purification process, etc., to meet the needs of industrialization and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Construction of recombinant strains producing amino acid deaminase mutants

[0028] The nucleotide sequence of the L-AAD mutant is shown in SEQ ID NO: 1, which is further optimized by codons suitable for the E. coli expression system, and the nucleotide sequence of the mutant is shown in SEQ ID NO: 2. The GC content was 44.0%, and the codon adaptability index (CAI) in E. coli was 0.269. After optimization, the GC content was 51.4, and the CAI was improved to 1.0. The nucleotide sequence of SEQ ID NO: 2 was synthesized by whole gene, and ligated into pET24a vector, and recombinantly expressed in E. coli BL21 (DE3), and the strain was named as E. coli-PM-LAAD. After codon optimization, the L-AAD enzyme activity increased from 2.37U / mL to 3.21U / mL, and the enzyme activity increased by 35.4%.

Embodiment 2

[0029]Example 2: Influence of nutrient conditions on the production of amino acid deaminase by fermentation

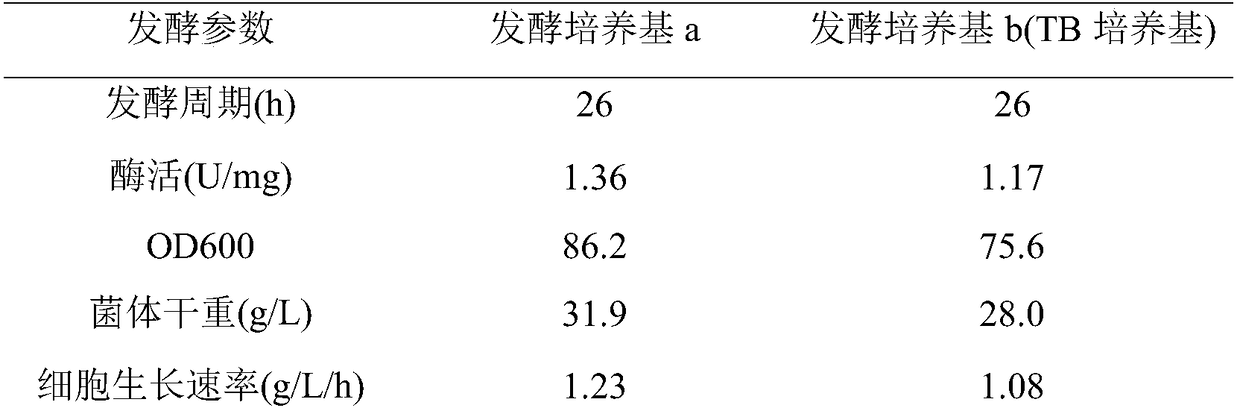

[0030] (1) The components of fermentation medium a are: glycerol 6g / L, yeast powder 20g / L, soybean peptone 5g / L, K 2 HPO 4 ·12H 2 O 2.5g / L, KH 2 PO 4 5.0g / L, metal ion solution 10mL / L.

[0031] The composition of the metal ionic liquid is: FeSO 4 ·7H 2 O 5g / L, CaCl 2 2g / L, ZnSO 4 ·7H 2 O 1.2g / L, MnSO 4 ·4H 2 O 0.4g / L, (NH 4 ) 6 MoO 24 ·4H 2 O 0.1g / L, H 3 BO 3 0.5g / L.

[0032] Fermentation medium b is TB medium: glycerol 4g / L, yeast powder 24g / L, soy peptone 12g / L, KH 2 PO 4 2.31g / L, K 2 HPO 4 .3H 2 O 12.54g / L.

[0033] The ingredients of the feed medium are: glycerol 400-600g / L, yeast powder 5-8g / L, MgSO 4 ·7H 2 O 6~10g / L.

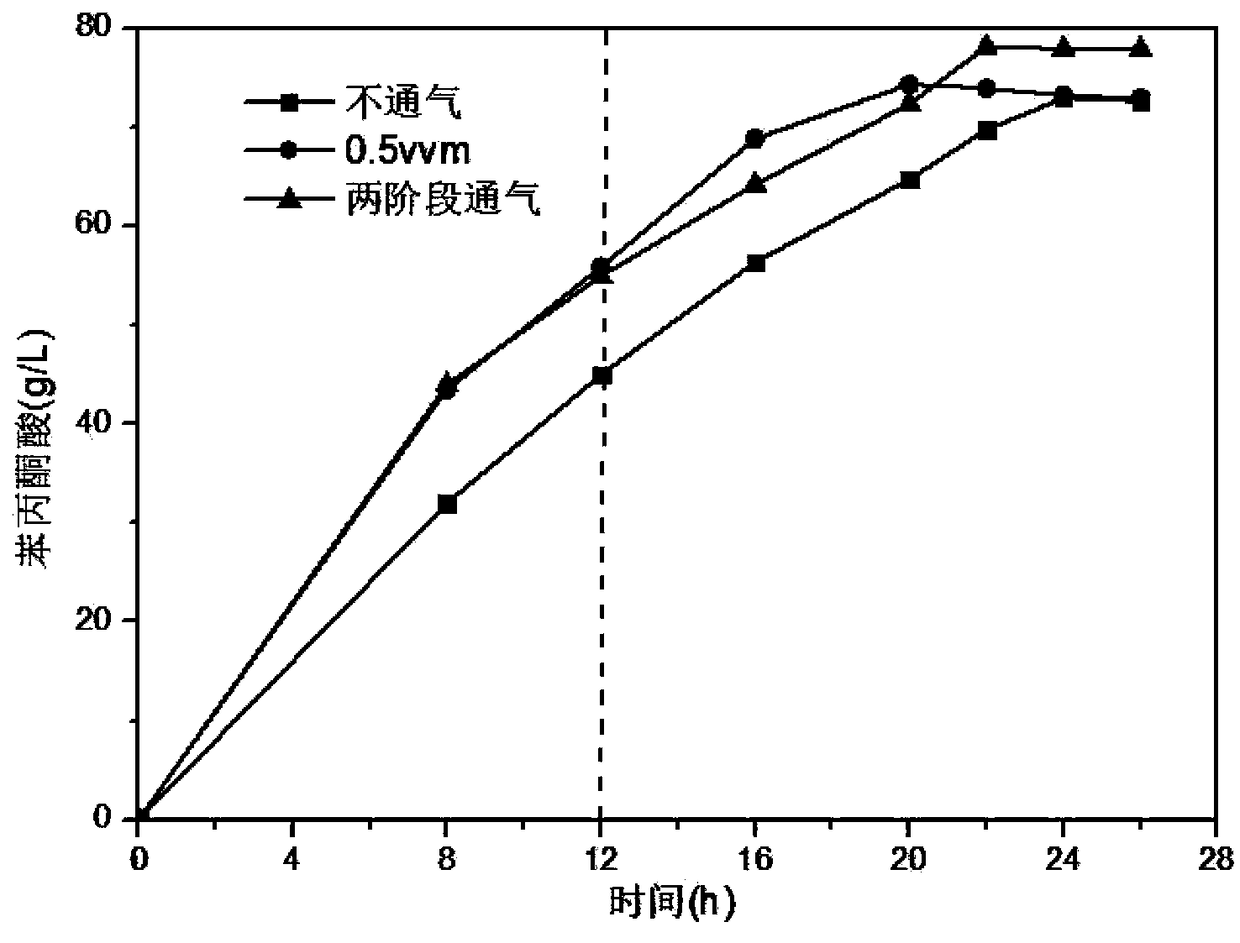

[0034] (2) E.coli-PM-LAAD in Example 1 was inoculated into LB seed medium (Kanamycin sulfate 100mg / L), 37°C, 200rpm shaking culture for 10-12h, respectively inoculated according to 5% inoculation amount on Fermentation me...

Embodiment 3

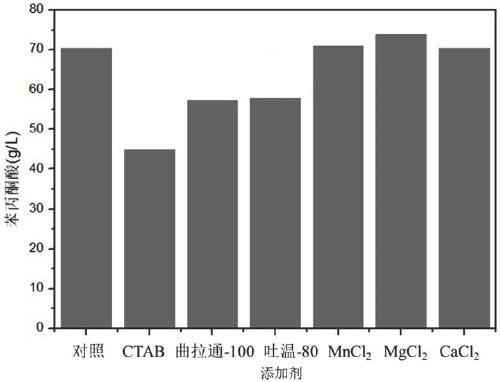

[0039] Example 3: Effects of additives on whole cell transformation to produce phenylpyruvate

[0040] The E.coli-PM-LAAD wet cells obtained in the fermentation medium a of Example 2 were used as a cell catalyst for converting phenylalanine to produce phenylpyruvate. In 1L transformation system, use pH 7.5 Tris-HCl buffer to dissolve L-phenylalanine 75g / L, wet cell 30g / L, 4mol / L NaOH solution to control pH 7.5~8.0, temperature 25℃, stirring speed 400rpm , ventilation volume was controlled at 0.5vvm, 0.1% CTAB, 0.1% Triton-100, 0.1% Tween-80, 2mmol / L MnCl were added respectively 2 , 2mmol / L MgCl 2 , 2mmol / L CaCl 2 , to examine the effect of additives on the yield of PPA. The experimental results are as figure 2 : MgCl 2 It has a certain promotion effect on the yield of PPA, the yield increased from 70.4g / L to 73.9g / L, and the conversion rate increased from 94.4% to 99.1%; other metal ions had no obvious effect on the conversion results; the addition of surfactants had no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com