Excavation-controllable foundation pit model test device and method

A model test device and foundation pit technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of model box size limitation, difficulty in accurately measuring the deformation of enclosure structures, etc., to achieve convenient simulation and avoid man-made Disturbing, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

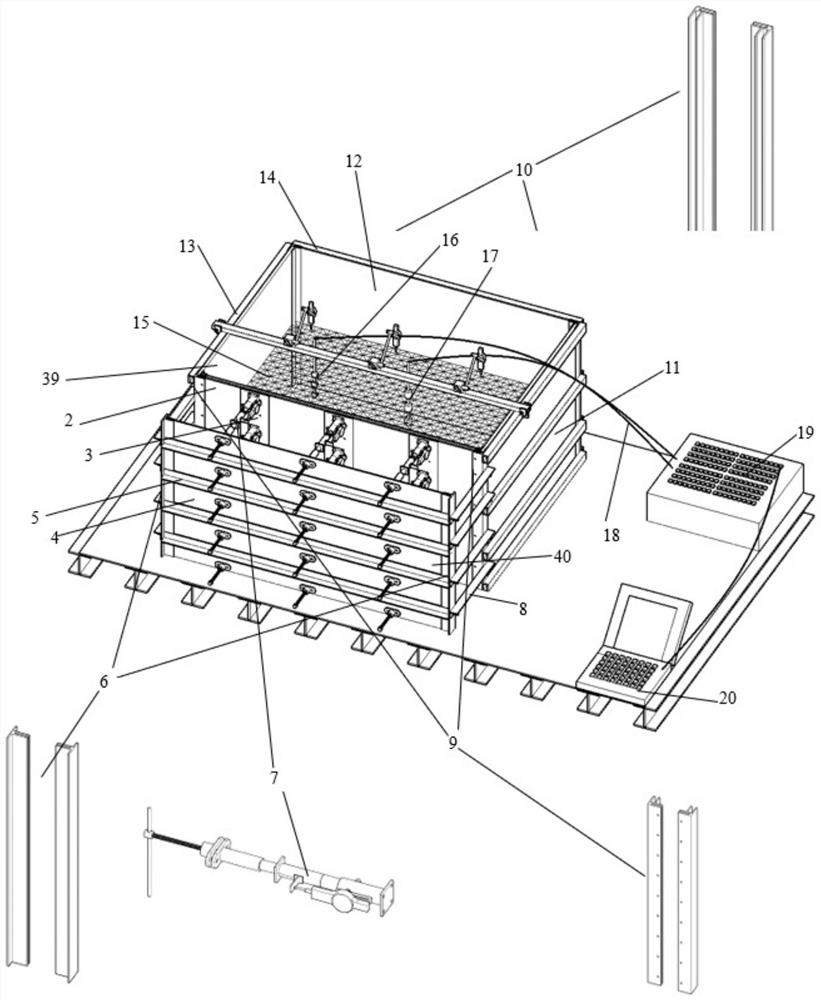

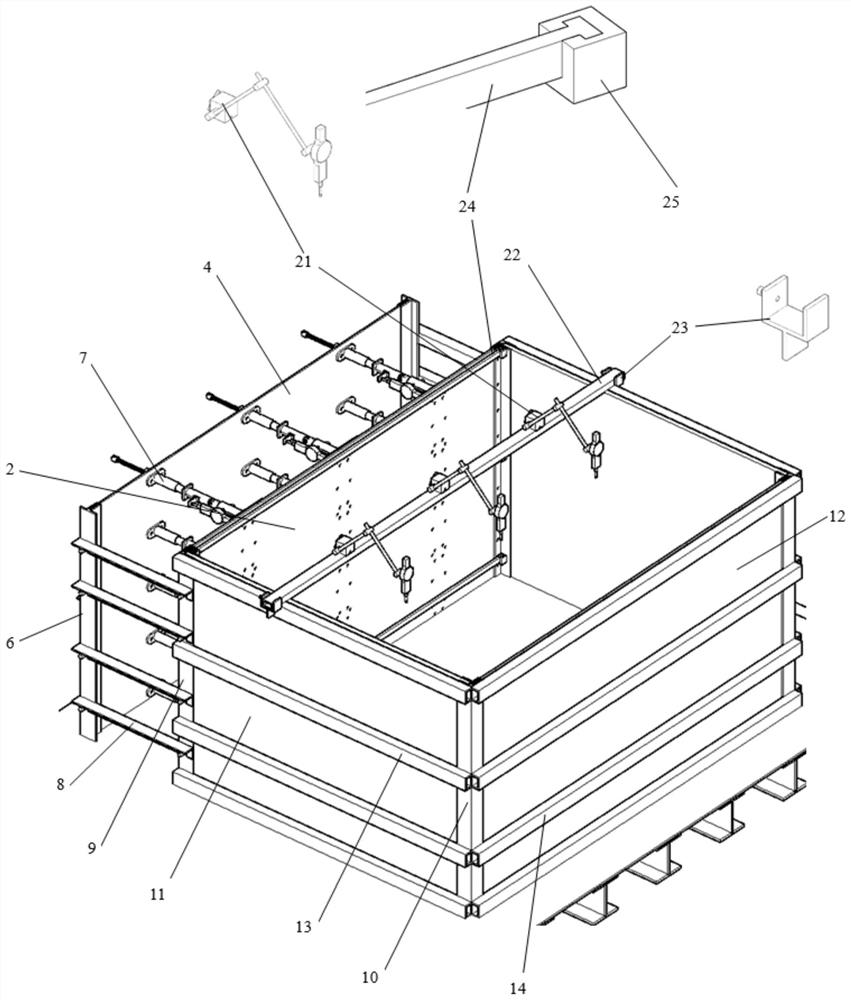

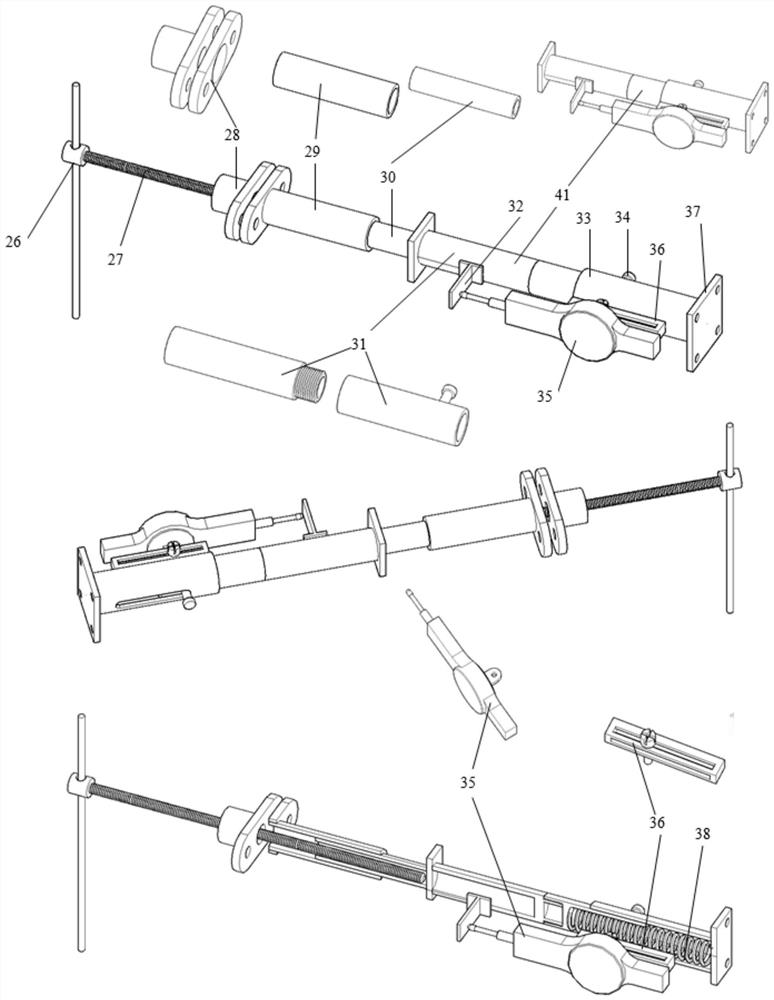

[0066] Embodiment 1 of the present application provides a controllable excavation pit model test device, including a model box outer frame 39, simulated soil 15, support baffle parts 40, support parts 7 and test instrument assemblies.

[0067] The model box outer frame 39 is composed of base 1, front column 9, rear column 10, enclosure baffle plate 2, plexiglass side panel 11, back panel 12, side panel reinforcement rib 13, back panel reinforcement rib 14, front Pull rod 24 forms. The base 1 is formed by welding 4 pieces of 2m×1.25m steel plates and 11 I-beams with a height of 10cm. The base 1 is used as a platform for the model test to ensure the stability of each part of the model test. The front column 9 is in order to connect the enclosure baffle 2 and the plexiglass side panel 11, so the front column 9 contains the slots of the enclosure baffle 2 and the plexiglass side panel 11, the front column is 1.1m high, and the section is as attached Figure 9 shown. In addition...

Embodiment 2

[0073] Embodiment 2 of the present application provides an assembly and test method of a controllable excavation pit model test device, the steps are as follows:

[0074] S1. Complete the construction of the base 1 with iron plates and I-beams. Weld support baffle column 6, front column 9 and rear column 10. Weld the side plate reinforcing ribs 13 and insert the plexiglass side plate 11. The front tie rod bearing 25 is welded on the top of the front column 9, and the two ends of the front tie rod 24 are inserted in the slot of the front tie rod bearing 25. Insert the back plate 12, and weld the back plate reinforcing ribs 14. Insert the support baffle 4 in the slot of the support baffle column 6, and weld the support baffle reinforcement rib 5. Insert the enclosure baffle 2 in the slot of the front column 9, install the supporting part steel backing plate 3 on the enclosure baffle 2, install the supporting part 7, install the side connecting rod 8 of the supporting baffle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com