Optical fiber exchange box for communication engineering construction

A communication engineering and switching box technology, which is applied in the field of optical fiber switching boxes for communication engineering construction, can solve the problems of insufficient buffering to protect internal components, difficulty in effectively guaranteeing safety, and fluctuations in internal components, so as to improve service life. , Avoid the danger of long-term high-altitude work, and prevent the effect of rainwater accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

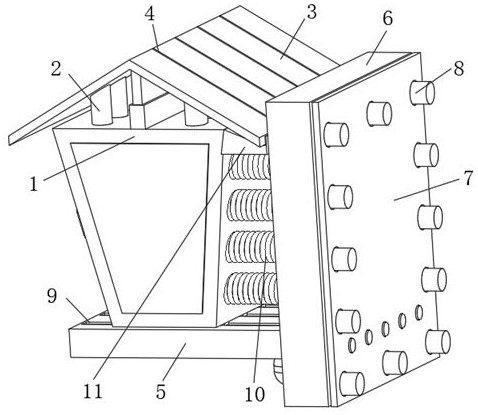

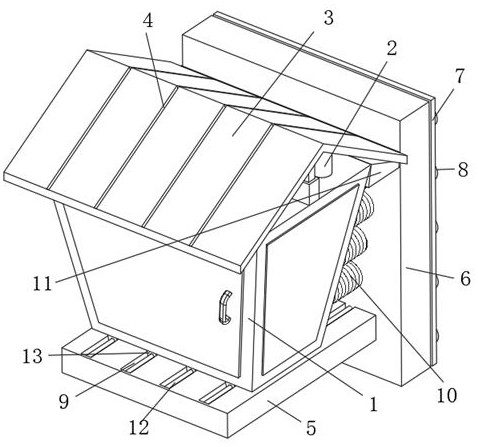

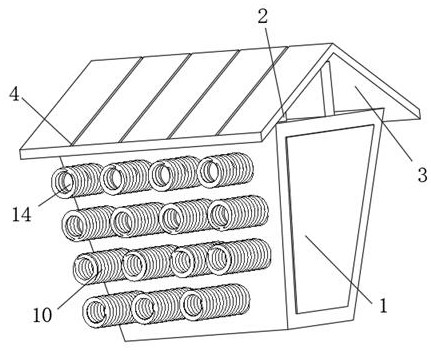

[0023] see Figure 1-6 , the present invention provides the following technical solutions: a fiber exchange box for communication engineering construction, including a main body 1, two ends of the main body 1 are provided with cooling holes for heat dissipation, and the lower end of the main body 1 is provided with a sliding block 13 connected to the connecting base plate 5 , the connecting bottom plate 5 is provided with a sliding groove 9 for the limiting sliding action of the main body 1, the other end of the connecting bottom plate 5 is fixedly connected with the side connecting plate 6 through bolts, and the connection between the connecting bottom plate 5 and the side standing connecting plate 6 is provided with two The motor used for transmission, the side connecting plate 6 is provided with evenly distributed transmission rods 8, and a rubber pad 7 for increasing the compactness of the connection is also provided. The other end of the side standing connecting plate 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com