3D printing precision forming machine for sand mold of side-wall-free sand box

A 3D printing and precision forming technology, applied in the direction of casting mold components, molding machine parts, casting molds, etc., can solve the problems of sand box weight, motion mechanism stability, precision influence, increase transfer facility load and cost, etc. , to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

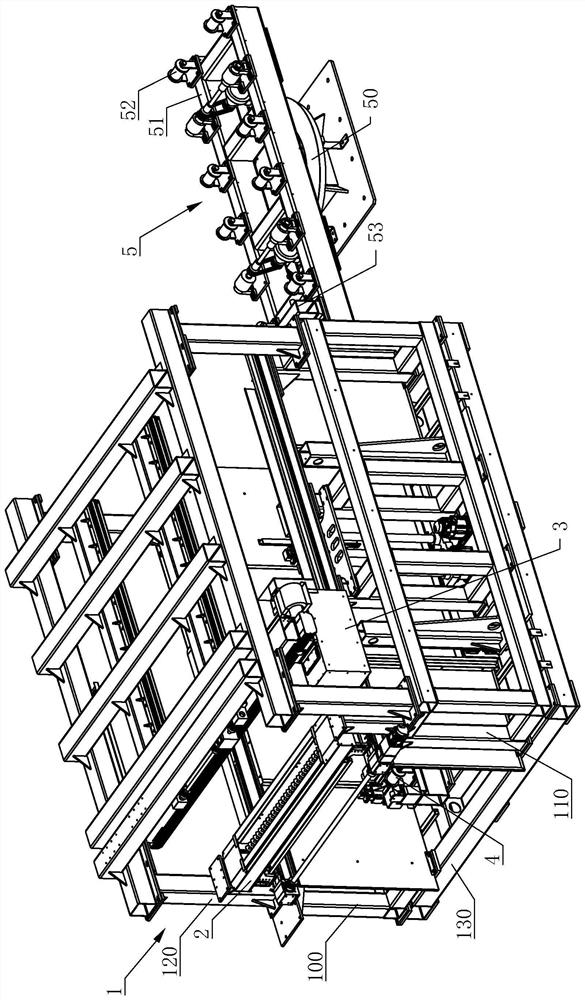

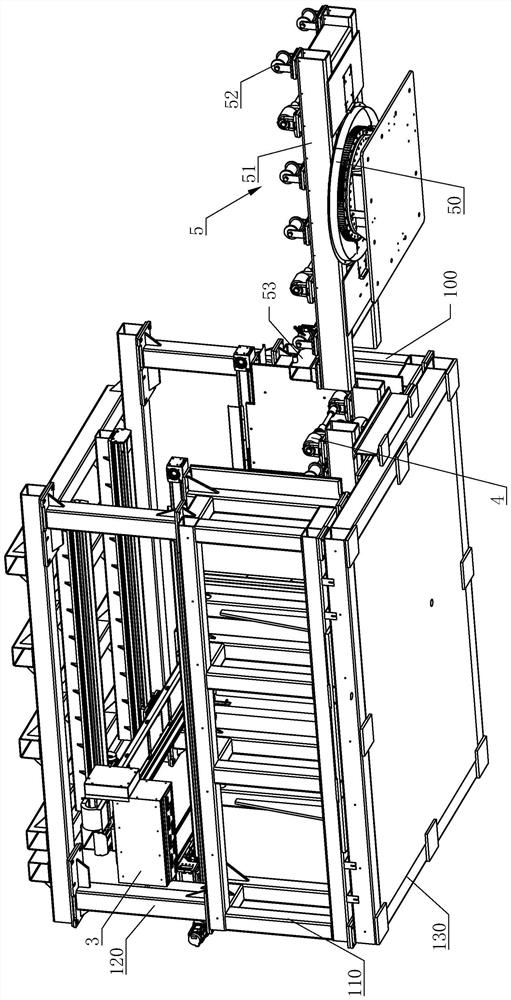

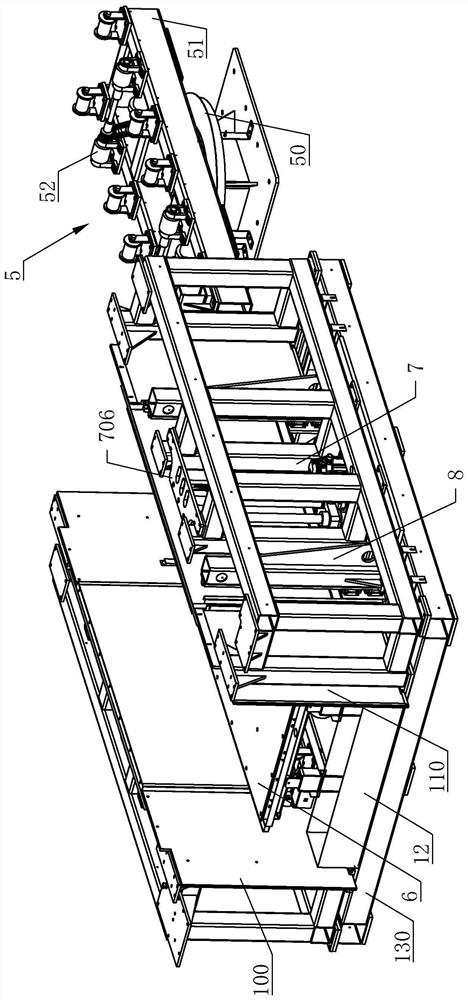

[0034] Such as Figure 1 to Figure 8Commonly shown, a 3D printing precision molding machine without a sidewall sand box, including a main frame 1 and a sand box 6, the sand box 6 includes a printing plate 60, and the main frame 1 is respectively provided with a transfer mechanism 4, a bracket 9, The lifting mechanism 7, the sanding mechanism 2 and the printing mechanism 3 that drive the lifting bracket 9, the bracket 9 rides on the transfer mechanism 4, and the lifting mechanism 7 is connected with the bracket 9. After the sand box 6 is transported in place (transported to the forming machine), th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap