Efficient and energy-saving storage type flexible feeding assembly and rapid assembly compatible device

A high-efficiency, energy-saving and flexible technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor product appearance, long retrieving time, low efficiency, etc., and achieve versatility and functional compatibility, assembly High efficiency and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

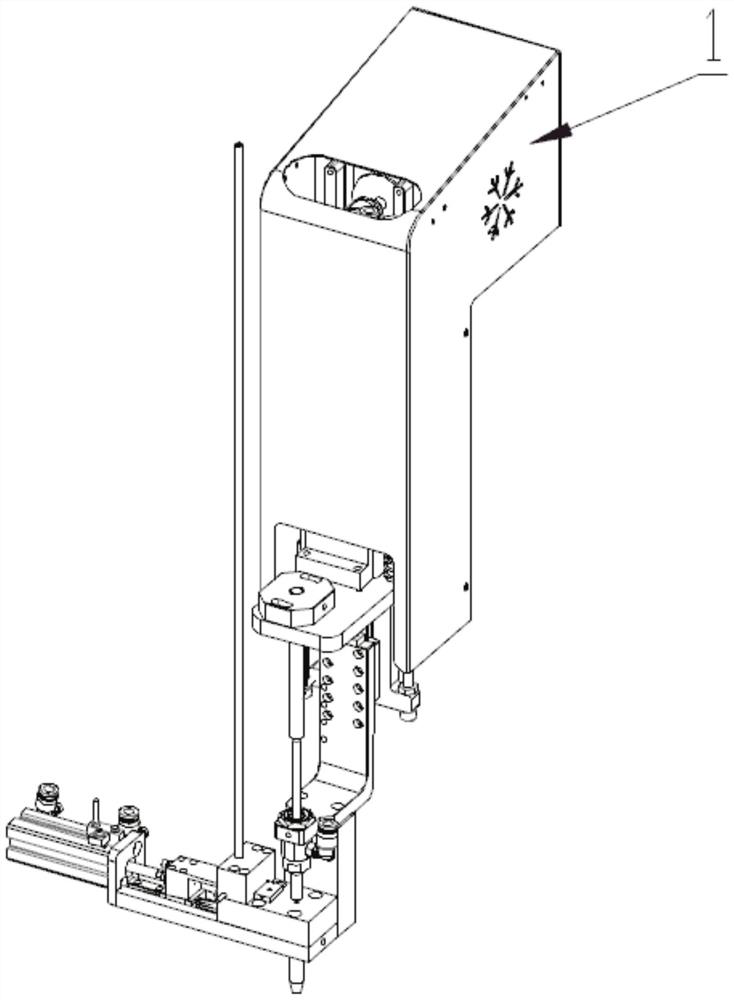

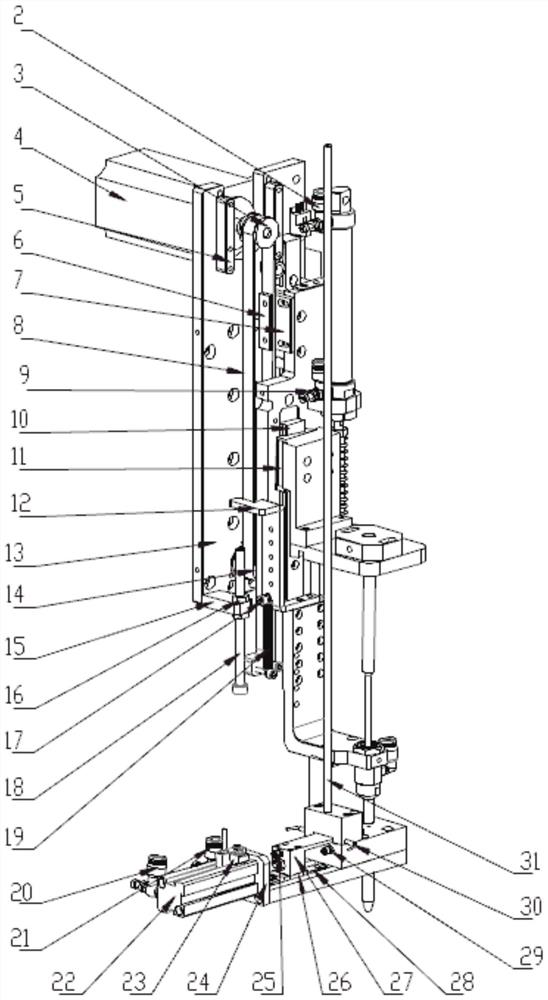

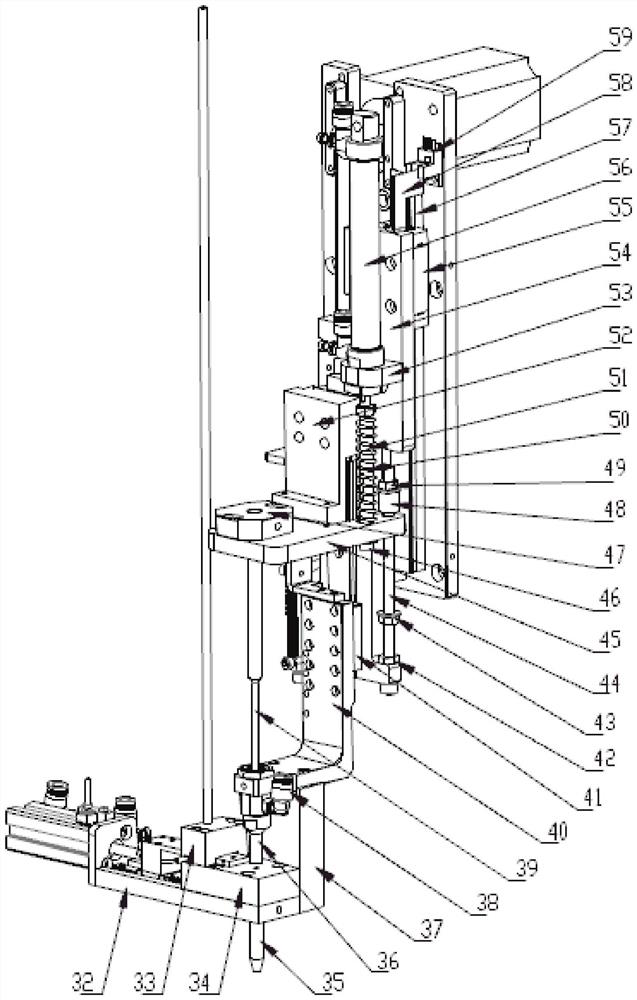

[0040] see Figure 1-3 , a high-efficiency and energy-saving storage type flexible feed assembly and quick assembly compatible device, including a sheet metal protective cover, the inner wall of the sheet metal protective cover is fixedly connected with a power drive assembly, and the flexible feed assembly assembly and quick assembly assembly are fixed on the power On the driving component, the storage type automatic feeding component is fixed on the flexible feeding assembly component and the quick assembly component, and the material is automatically loaded through the storage type structure. According to the product size and product performance requirements, it can be reasonably selected or flexible and stable. The feeding assembly method, or the efficient quick assembly method, generally speaking, some particularly small material assemblies (such as extremely small magnets, copper pillars, screws, etc.) are suitable for flexible feeding assembly methods, because flexible f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com