Servo hydraulic-control tire formation machine

A tire building machine and hydraulic technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of energy conversion not as high as hydraulic transmission, loose fastening screws of equipment, large amount of hydraulic oil, etc., and achieve high energy utilization rate , the effect of suppressing the rise of oil temperature and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

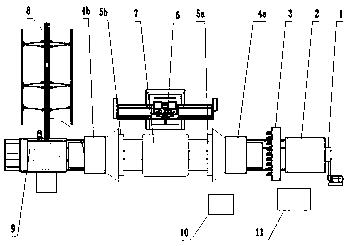

[0020] Such as figure 1 Shown: 1 folding drum device, 2 main box, 3 clamping traction device, 4a fixed end of front and back wrapping device, 4b moving end of front and back wrapping device, 5a fixed end of buckle ring, 5B moving end of buckle ring, 6 forming drum, 7 Roller device, 8 guide device, 9 rotating tailstock device, 10PLC control cabinet, 11 servo hydraulic station;

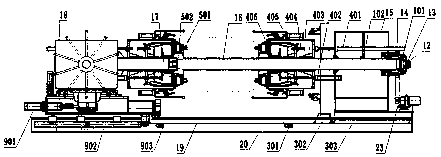

[0021] Such as figure 2 Shown: 12 rotary joint, 13 hydraulic distributor, 14 transmission disc, 15 main chassis, 401 outer sleeve oil cylinder, 402 capsule oil cylinder, 403 outer sleeve, 404 finger-shaped positive pack oil cylinder, 405 finger-shaped positive pack seat, 406 Capsule turn-up seat, 16 main shaft, 17 support shaft, 18 expansion guide shaft, 19 rotating chassis, 20 machine base, 21, transmission disc, 22 belt, 23 servo motor, 501 buckle cylinder, 502 buckle seat;

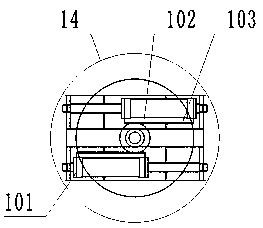

[0022] Such as image 3 Shown: 101 folding drum oil cylinder, 102 gears, 103 racks;

[0023] Such as Figure 4 Shown: 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com