Friction nano-generator device for collecting wind energy by using positive and negative rotating blades and working method of friction nano-generator device

A nano-generator, forward and reverse technology, applied to friction generators, wind turbines at right angles to the wind direction, wind turbines, etc., can solve the problems of low wind energy utilization rate, difficulty in achieving wind energy utilization rate, poor starting performance, etc. Achieve the effects of compact structure, small footprint and high output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

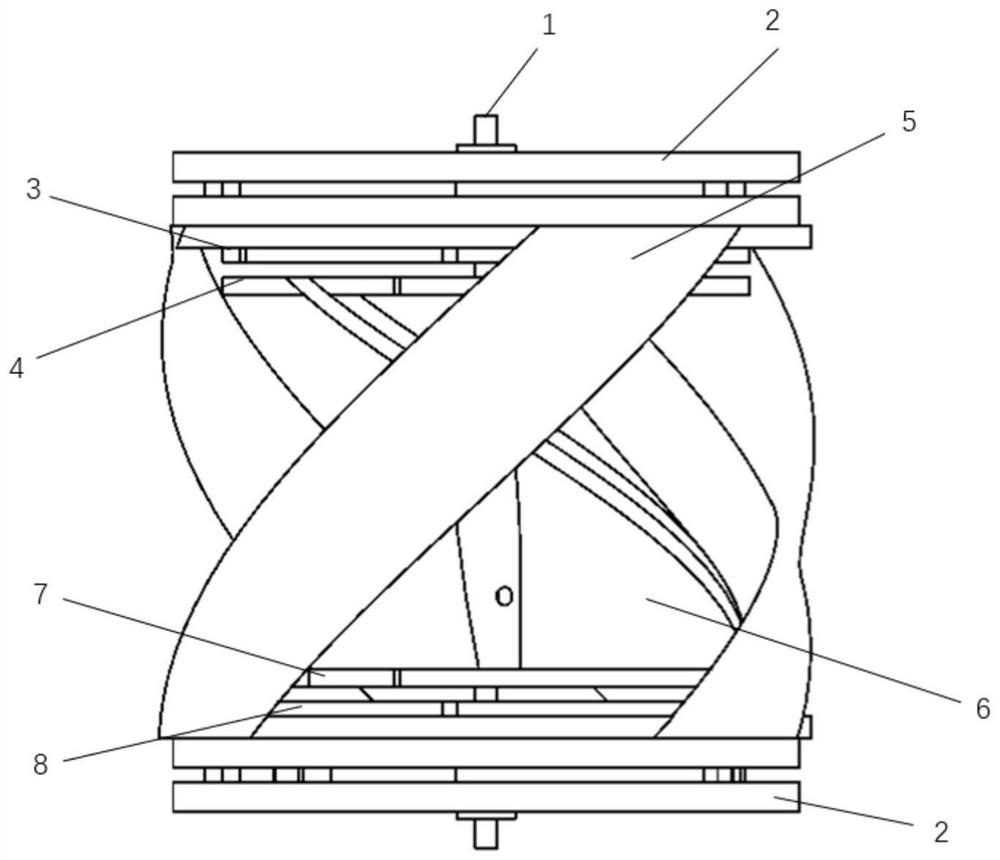

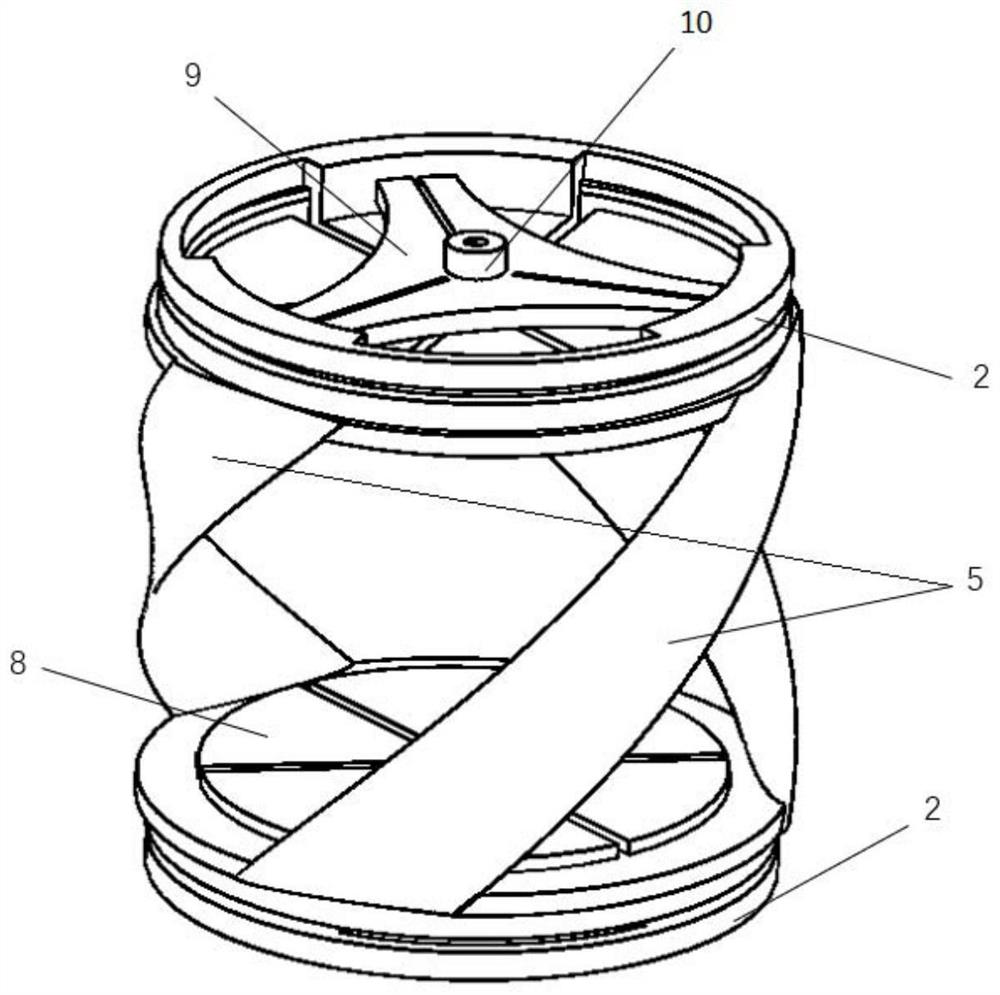

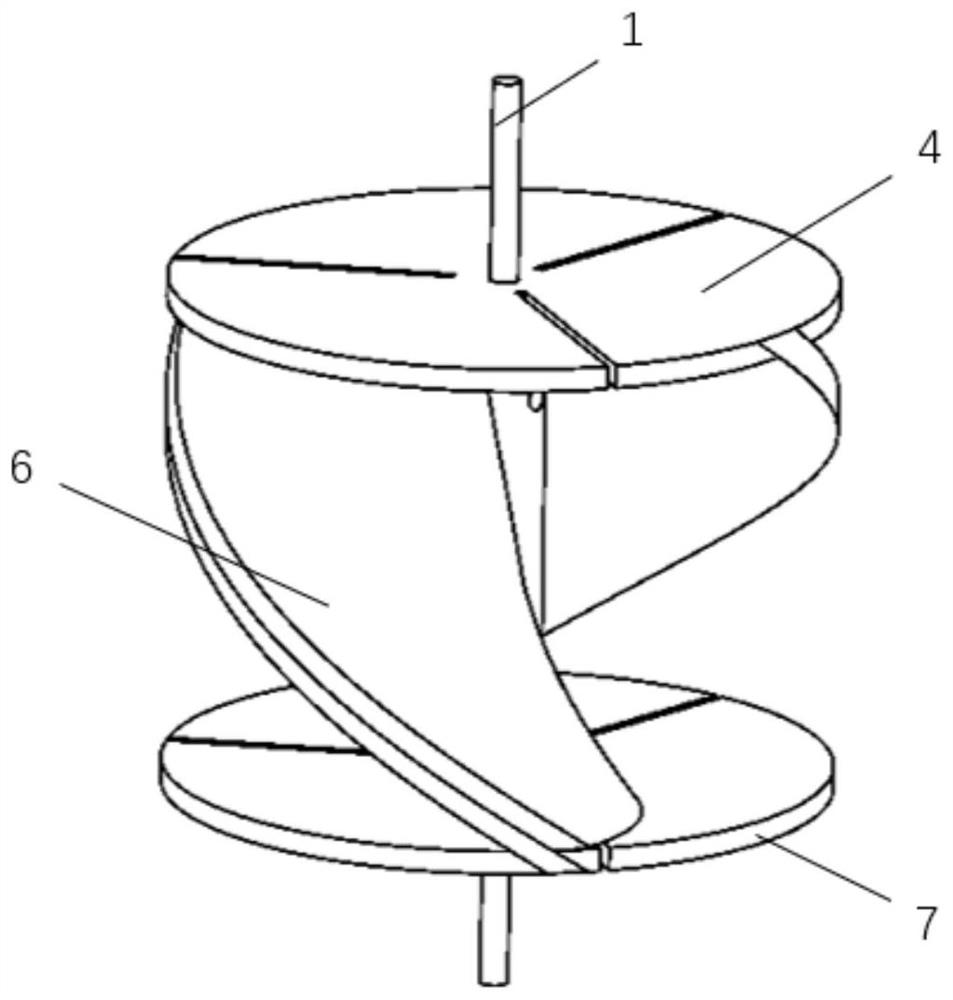

[0049] Such as Figure 1-3 As shown, in order to solve the problems existing in the prior art, the present invention designs a power generation device, that is, a friction nanogenerator device that uses forward and reverse blades to collect wind energy, so that it can use low wind speed and have a higher wind energy utilization rate , The higher wind energy conversion rate can collect more wind energy, and at the same time, it can also have a lower resistance torque in the generator part. The power generation device includes forward and reverse double blades and a rotating disk type friction nanometer generator.

[0050] In this embodiment, the forward and reverse double blades can be in the form of two-two cooperation of different blades among the lift type and the resistance type. During the cooperation process, it should be noted that the rotation directions of the two are opposite to achieve the purpose of forward and reverse rotation. , the purpose of forward and reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com