VPSA gas separation system and control method thereof

A gas separation and control method technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as small range of adjustable working conditions, high manufacturing costs, and small high-efficiency working range of large centrifugal units. To achieve the effect of improving production efficiency, reducing maintenance costs and ensuring the maintenance of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

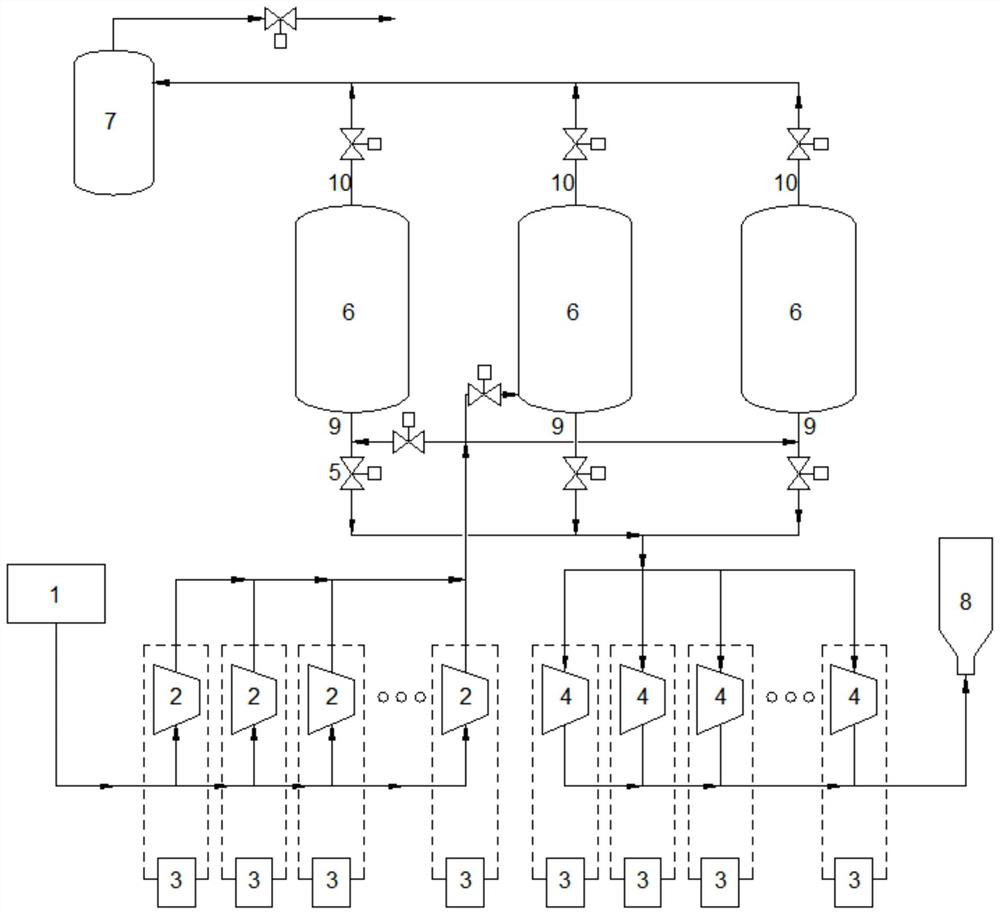

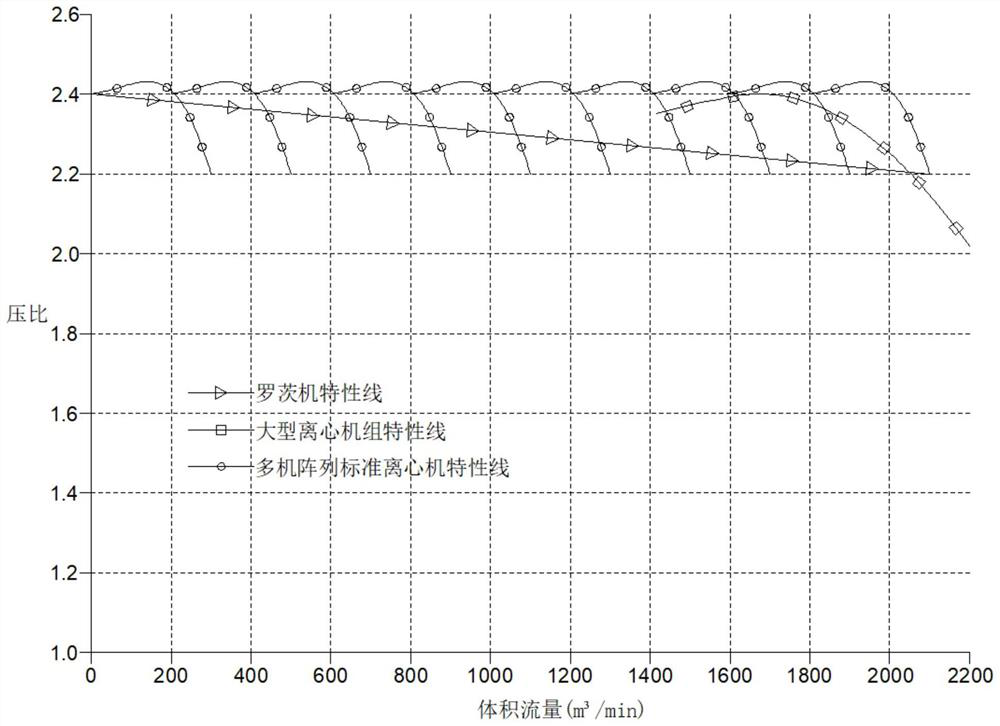

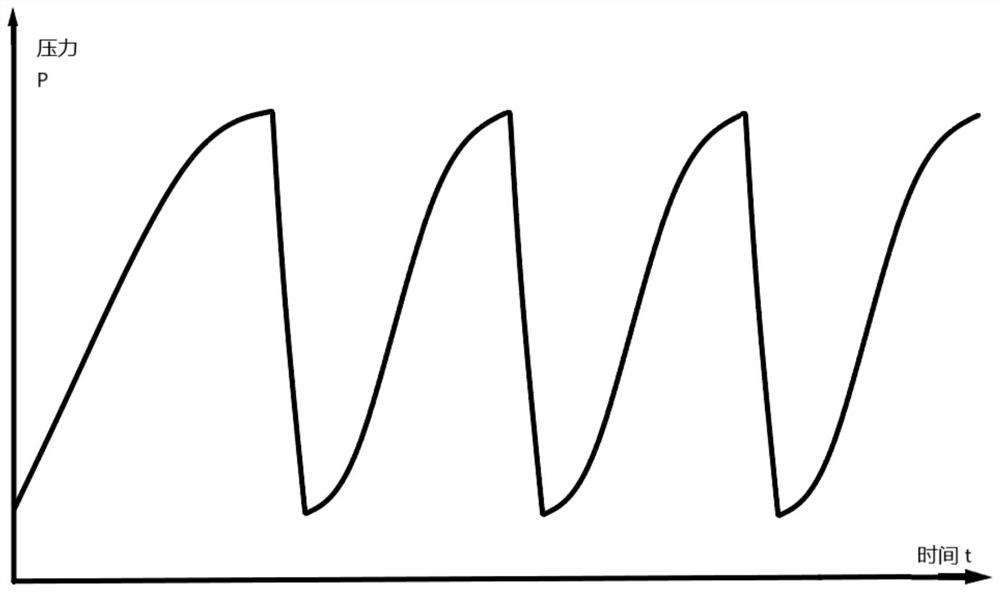

[0029] Such as Figure 1-2 As shown, in order to expand the range of adjustable operating conditions of the turbine unit in the VPSA gas separation system and reduce the manufacturing cost of the turbine unit, the embodiment of the present invention proposes a VPSA gas separation system, including several turbines arranged in parallel and Gas separation components, several turbines are used to deliver air to the gas separation components or vacuumize, each turbine is connected to a drive motor and frequency converter 3, all frequency converters 3 are connected to a control device, and the control device is used to control the frequency conversion output of device 3.

[0030] The turbine unit includes two main pipelines and the centrifugal blower 2 or the centrifugal vacuum pump 4 fixedly connected to the two main pipelines, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com