Paint brushing device for telegraph pole

A utility pole and painting technology, applied in the direction of spraying device, etc., can solve the problems of potential safety hazards and low efficiency, and achieve the effects of reducing potential safety hazards, improving work efficiency, and being convenient to operate and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

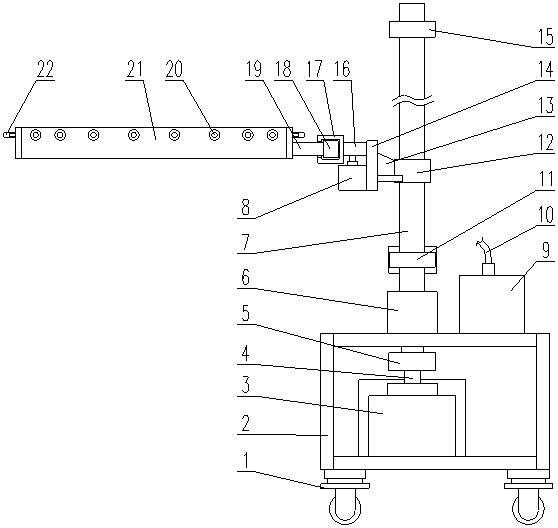

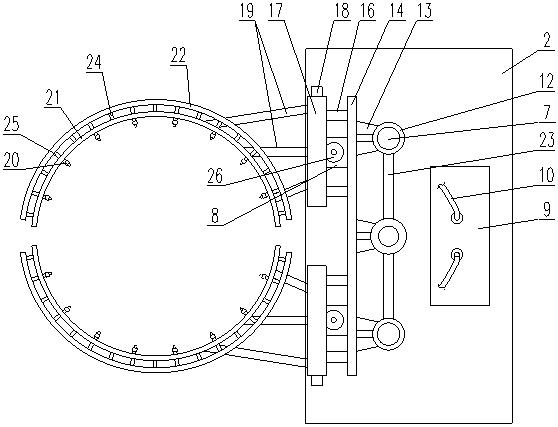

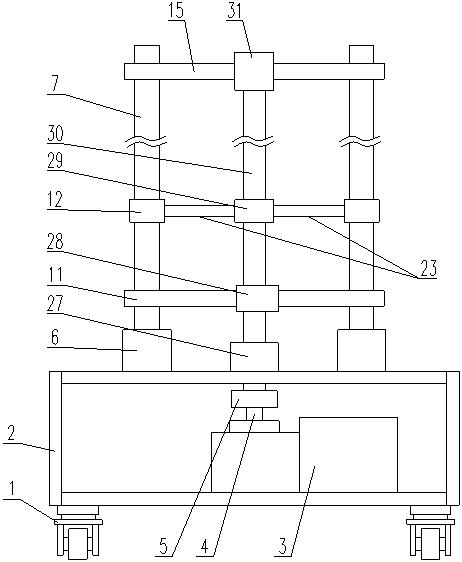

[0023] Such as Figure 1-5 As shown, the utility pole painting device includes a mobile trolley 2, and the top of the mobile trolley 2 is provided with a screw support 27 and a connecting base 6, and the connecting base 6 is provided with two and is located on the screw support. On both sides of the seat 27, the screw support 27 is rotatably connected with a driving screw 30, the connecting base 6 is fixedly connected with a guide rod 7, and the lower end of the screw support 27 extends into the inside of the trolley 2, The inside of the trolley 2 is provided with a drive motor 3, the drive shaft 4 of the drive motor 3 is connected to the lower end of the screw support 27; the drive screw 30 is threadedly connected with a drive sleeve 29, and the guide The rod 7 is slidably connected with a guide sleeve 12, a guide connecting rod 23 is connected between the drive sleeve 29 and the guide sleeve 12, and a supporting horizontal plate 14 is connected to the side of the guide sleev...

Embodiment 2

[0026] Such as Figure 1-7 As shown, the utility pole painting device includes a mobile trolley 2, and the top of the mobile trolley 2 is provided with a screw support 27 and a connecting base 6, and the connecting base 6 is provided with two and is located on the screw support. On both sides of the seat 27, the screw support 27 is rotatably connected with a driving screw 30, the connecting base 6 is fixedly connected with a guide rod 7, and the lower end of the screw support 27 extends into the inside of the trolley 2, The inside of the trolley 2 is provided with a drive motor 3, the drive shaft 4 of the drive motor 3 is connected to the lower end of the screw support 27; the drive screw 30 is threadedly connected with a drive sleeve 29, and the guide The rod 7 is slidably connected with a guide sleeve 12, a guide connecting rod 23 is connected between the drive sleeve 29 and the guide sleeve 12, and a supporting horizontal plate 14 is connected to the side of the guide sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com