Industrial intelligent stirring equipment

A mixing equipment and industrial technology, applied in the field of industrial intelligent mixing equipment, can solve the problems of low mixing efficiency, uneven mixing of mixed materials, affecting the performance of injection molding products, etc., and achieve the effect of improving mixing efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

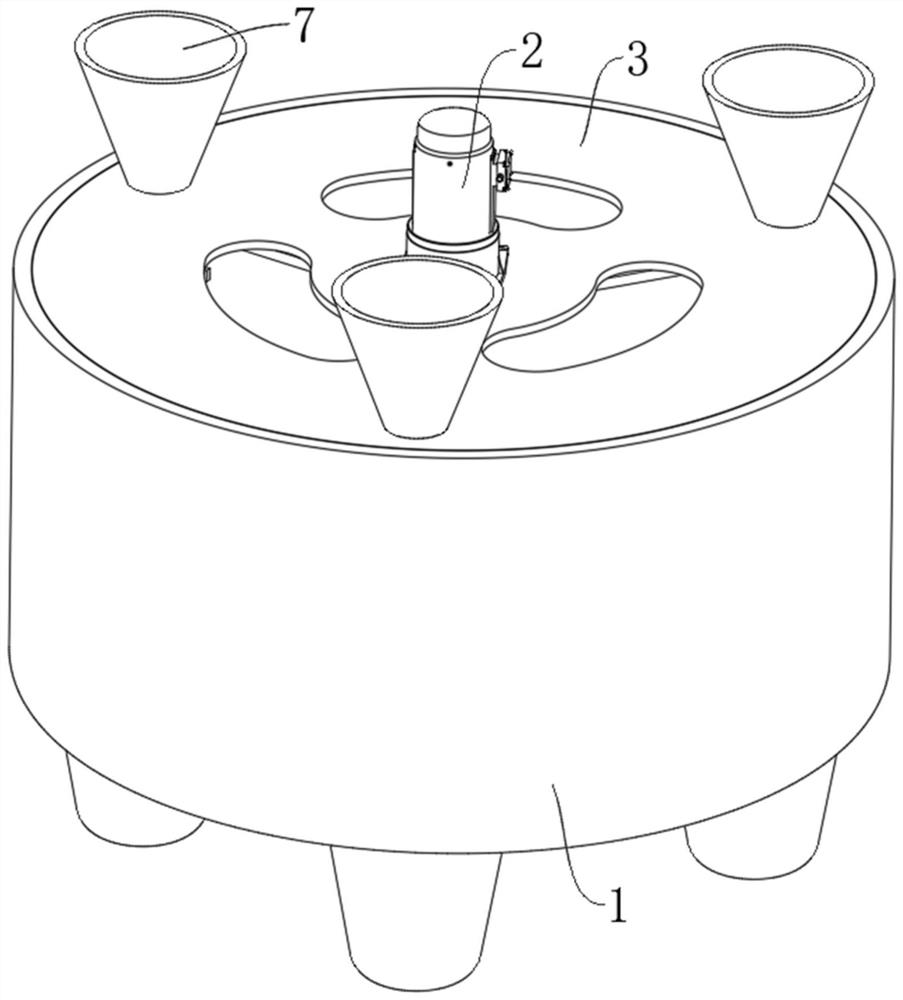

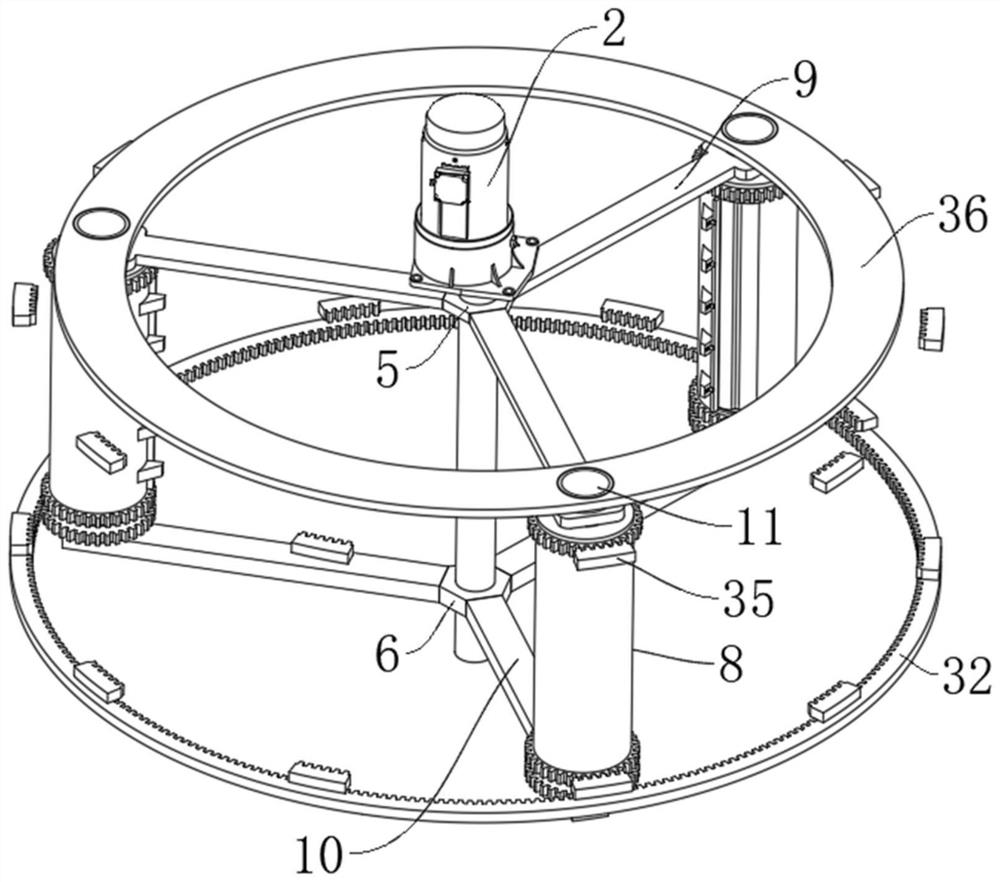

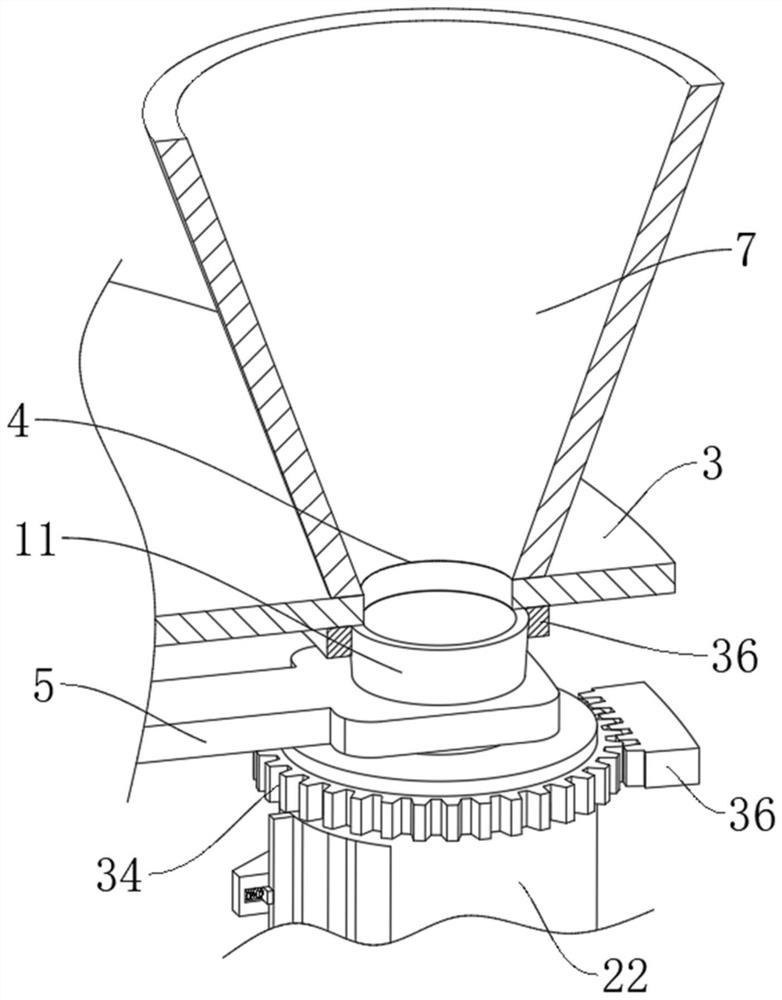

[0031] see Figure 1-10 , the present invention provides a technical solution: an industrial intelligent mixing equipment, including a stirring tank 1, a driving motor 2, a first fixed block 5, a second fixed block 6, a plurality of storage hoppers 7 and a plurality of sets of conveying devices 8 , the stirring tank 1 is fixed with a mounting plate 3, and the mounting plate 3 is provided with a plurality of feed ports 4, and the driving motor 2 is fixed on the mounting plate 3 through a motor base, and the output of the driving motor 2 The end is connected to the stirring shaft through a coupling, the first fixed block 5 and the second fixed block 6 are fixedly connected to the stirring shaft, the storage hopper 7 is fixed on the mounting plate 3, and is connected to the stirring shaft through the feed port 4 The tank 1 is connected, and the delivery device 8 is used to deliver the mixed additive to the stirred tank 1 , and the delivery device 8 is installed in the stirred tan...

Embodiment 2

[0038] see Figure 3-Figure 10 , this embodiment is a further description of Embodiment 1, an industrial intelligent mixing equipment, including a stirring tank 1, a drive motor 2, a first fixed block 5, a second fixed block 6, a plurality of storage hoppers 7 and a plurality of The feeding device 8, the stirring tank 1 is fixed with a mounting plate 3, the mounting plate 3 is provided with a plurality of feeding ports 4, the driving motor 2 is fixed on the mounting plate 3 through a motor base, and the driving The output end of the motor 2 is connected to the stirring shaft through a coupling, the first fixed block 5 and the second fixed block 6 are both fixedly connected to the stirring shaft, the storage hopper 7 is fixed on the mounting plate 3, and is fed through The port 4 communicates with the stirred tank 1 , and the delivery device 8 is used to deliver the mixed additive to the stirred tank 1 , and the delivery device 8 is installed in the stirred tank 1 .

[0039] W...

Embodiment 3

[0045] see Figure 5-7 , this embodiment is a further description of other embodiments, an industrial intelligent mixing equipment, including a stirring tank 1, a drive motor 2, a first fixed block 5, a second fixed block 6, a plurality of storage hoppers 7 and a plurality of The feeding device 8, the stirring tank 1 is fixed with a mounting plate 3, the mounting plate 3 is provided with a plurality of feeding ports 4, the driving motor 2 is fixed on the mounting plate 3 through a motor base, and the driving The output end of the motor 2 is connected to the stirring shaft through a coupling, the first fixed block 5 and the second fixed block 6 are both fixedly connected to the stirring shaft, the storage hopper 7 is fixed on the mounting plate 3, and is fed through The port 4 communicates with the stirred tank 1 , and the delivery device 8 is used to deliver the mixed additive to the stirred tank 1 , and the delivery device 8 is installed in the stirred tank 1 .

[0046] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com