Automatic brake control device

A control device and automatic braking technology, applied in the direction of brake transmission, pneumatic brake, brake, etc., can solve the problems of slow inflation speed and poor braking effect, and achieve fast exhaust speed and good emergency braking effect. , the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

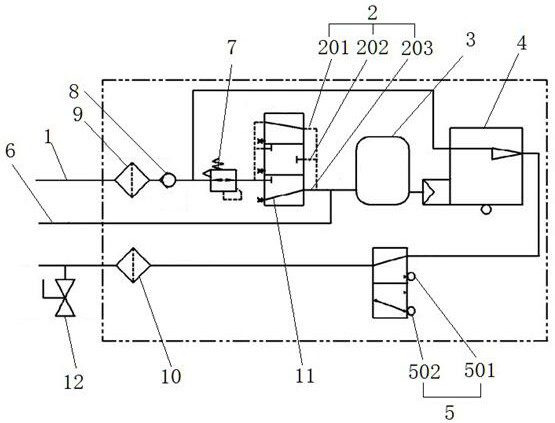

[0024] like figure 1 As shown, an automatic braking control device involved in this embodiment includes a main air duct 1, a main air dust filter 9, a one-way valve 8, a pressure reducing valve 7, a control valve 2, an equalizing air cylinder 3, Action valve 4, emergency exhaust valve 5, train pipe dust filter 10 and train pipe 6; exhaust train pipe ball valve 12 is set on the train pipe 6; the inner diameter of the total air pipe 1 is 21mm; the passage a11 The exhaust diameter is 16mm; the exhaust diameter of the emergency brake is 21mm; the control valve 2 includes a relief position 201, a pressure maintaining position 202 and a braking position 203, and the control valve 2 controls the The position of the control valve 2 ; the emergency exhaust valve 5 includes a normal position 501 and an emergency position 502 .

[0025] When the emergency exhaust valve 5 is placed in the normal position 501, the control device is in a normal working mode, and the normal working mode inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com