Heat treatment equipment for steel for sawteeth

A technology of heat treatment equipment and sawtooth, applied in the direction of heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problems of large space and impracticality, and achieve the effects of high automation, saving labor costs, and saving space and area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

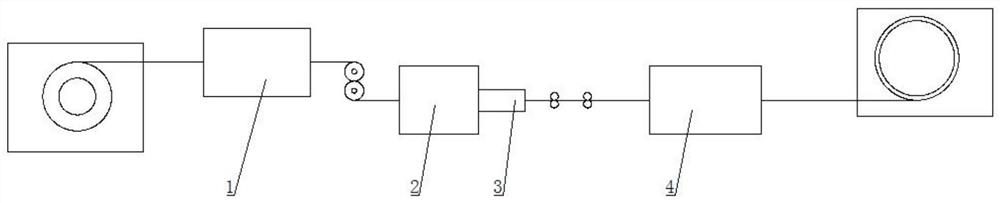

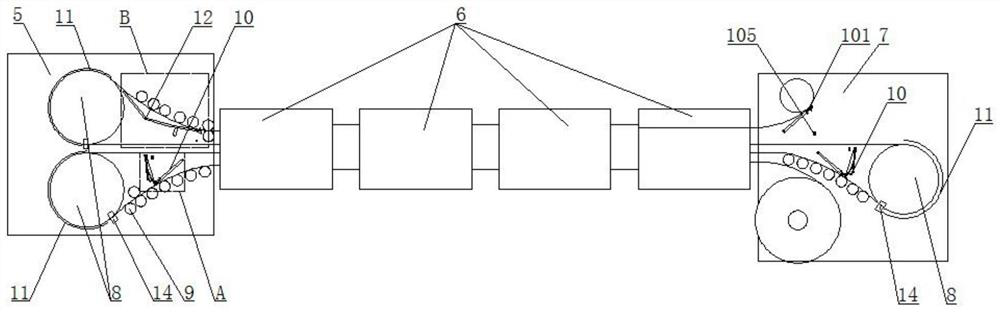

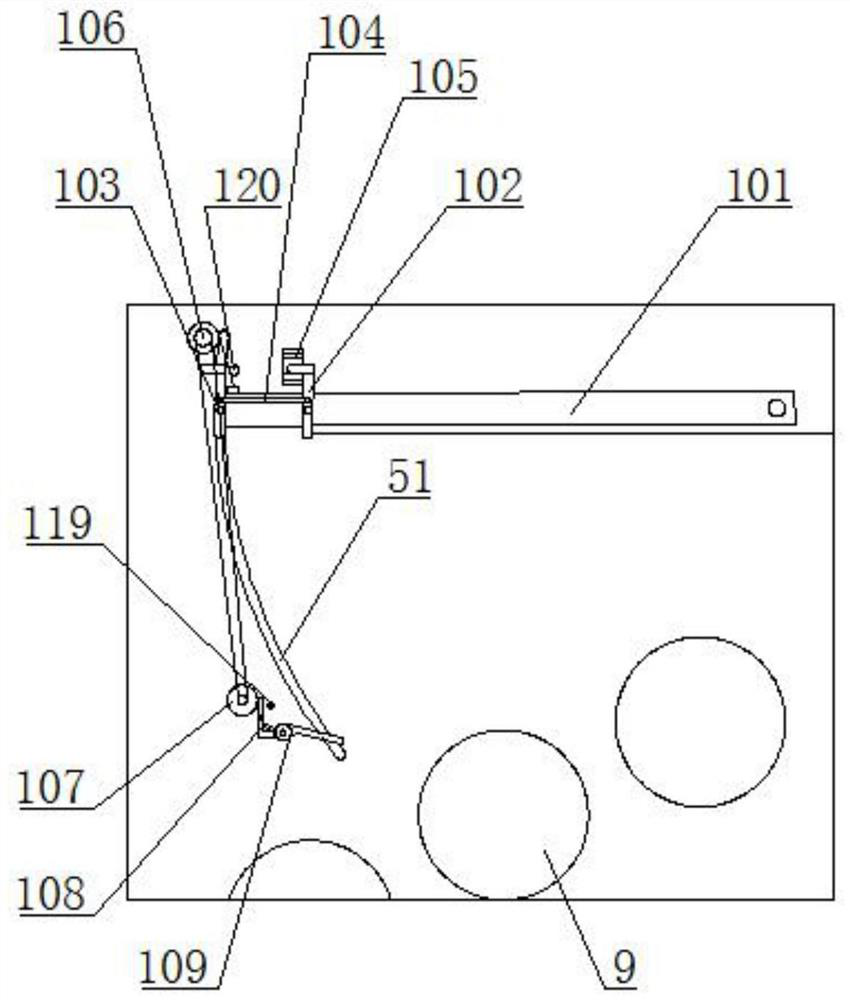

[0039] Such as Figure 1-21Shown is a heat treatment equipment for steel used in sawtooth, including a washing and drying machine 1 used in the first process, a quenching furnace 2, a cooling oil tank 3, a low-temperature tempering furnace 4 and a high-temperature tempering furnace 6 used in the second process. The steel material is Longsheng X32 steel strip. Here, passing through the two-section tempering furnace is defined as one-time tempering. The first process: the cleaned and dried steel strip passes through the quenching furnace 2, enters the cooling oil tank 3 to cool, and then enters the two-section tempering furnace. The low-temperature tempering furnace 4 and the cooling water tank complete the first tempering, where the tempering temperature is set to 580 degrees Celsius, the passing speed is controlled by the traction frequency converter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com