Fabric singeing machine

A technology of singeing machine and fabric, applied in singeing, mechanical cleaning, fabric surface trimming and other directions, can solve the problems of inconvenient temperature control, easy to burn fabric, energy consumption, etc., to protect the color, reduce dust, and be suitable for applications. Sexually wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

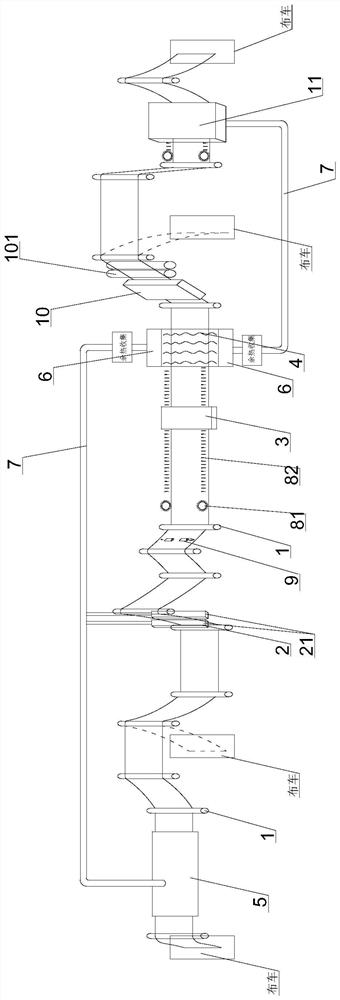

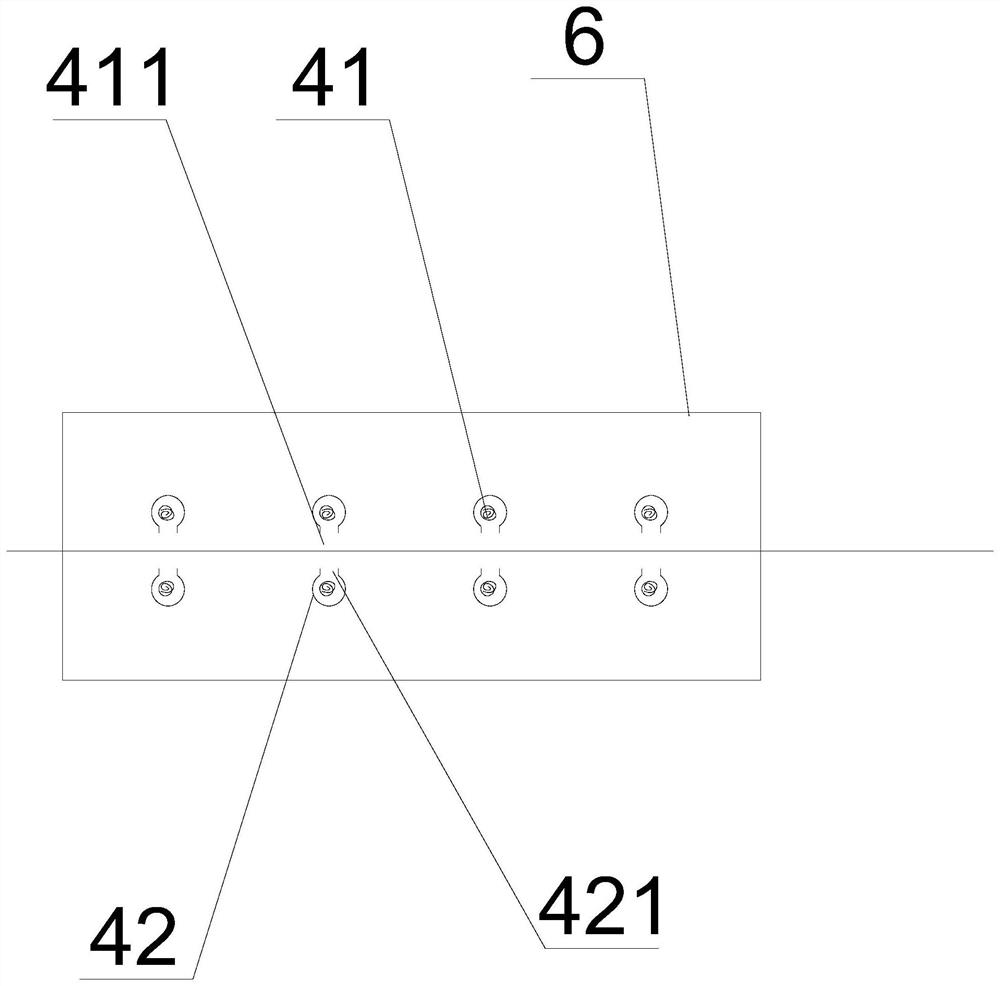

[0028] refer to figure 1 and figure 2 , a kind of fabric singeing machine of the present invention, comprises several cloth feeding rollers 1 and the fabric hot ironing device 2 that is connected successively by described cloth feeding roller 1, electrostatic field 3 and singeing device 4, and described fabric hot ironing device 2 includes at least two oppositely arranged hot air pipes 21, and a certain gap is provided between the two hot air pipes 21, and the fabric can pass through the gap, and the singeing device 4 includes several electric heaters arranged on the upper and lower sides of the fabric. Silk 41, the fabric passage 411 is arranged between the heating wires 41 on the upper and lower sides, and the fabric passes through the passage 411, and the left and right sides of the singeing device 4 are provided with dust collectors that can cooperate with it. Device 6, the dust suction device 6 is provided with a filter mechanism for filtering hairiness and dust, and th...

Embodiment 2

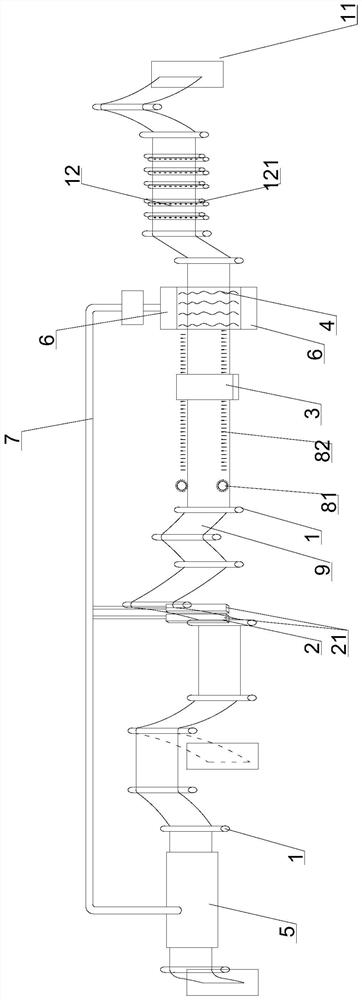

[0039] refer to figure 2 and image 3 On the basis of Embodiment 1, in this embodiment, the spraying device 10 and tenter dryer 11 are replaced with a second dust collection device 12, and the output end of the singeing device 4 is provided with a second dust collection device 12, The second dust suction device 12 includes several negative pressure suction pipes 121 arranged on the upper and lower sides of the fabric. Negative pressure strong suction pipe 121 can suck up the dust on the cloth surface, and also actively cool down simultaneously.

[0040] Working process of the present invention:

[0041] In the working process of a fabric singeing machine of the present invention, when gray cloth and yarn-dyed fabric are processed: the gray cloth fabric is first passed through the steaming pre-shrinking machine 5, so that the fabric shrinks as much as possible to reach a stable state, and then passes through the hot air pipe 21 , to further make the fabric shrink and flatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com