Pump station pump system high-pressure water lubricating device based on rotating speed

A lubricating device and high-pressure water technology, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of shortening the service life of bearings and journals, friction and wear of journal bearings, and low viscosity of lubricating media and other problems, to prevent friction, improve working life, and prevent wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail now in conjunction with accompanying drawing.

[0032] It should be noted that terms such as "upper", "lower", "left", "right", "front", and "rear" quoted in the invention are only for clarity of description, not for Limiting the practicable scope of the present invention, and the change or adjustment of the relative relationship shall also be regarded as the practicable scope of the present invention without substantive changes in the technical content.

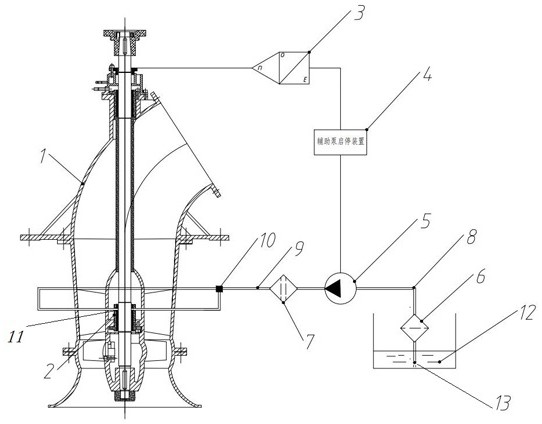

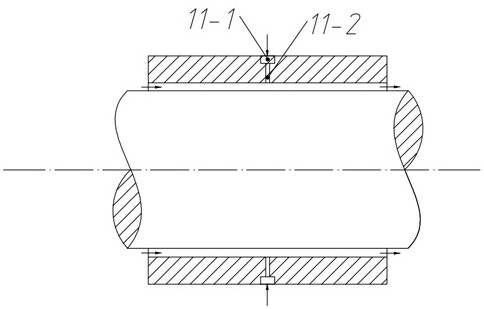

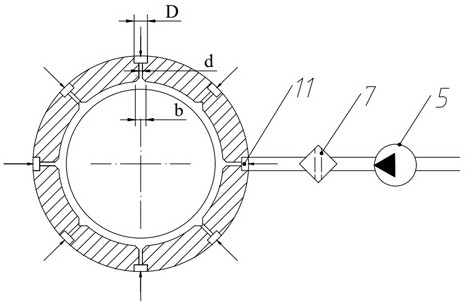

[0033] As shown in the attached figure, a high-pressure water lubricating guide device for a pumping station pump system based on rotational speed is characterized in that it includes a pump body 1, a water lubricating guide bearing 2, an auxiliary pump 5, a coarse filter 6, a fine filter 7, Water inlet pipe B8, water outlet pipe 9, joint 10. The input end of the coarse filter 6 is connected with one end of the water inlet pipe A13, and the other end of the water i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap