Synchronous automatic clutch oil supply slip ring suitable for high rotating speed

A synchronous automatic and clutch technology, applied in automatic clutches, clutches, transmission parts, etc., can solve problems such as oil supply difficulties, and achieve the effect of simple structure, simple lubrication system, and reduced requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

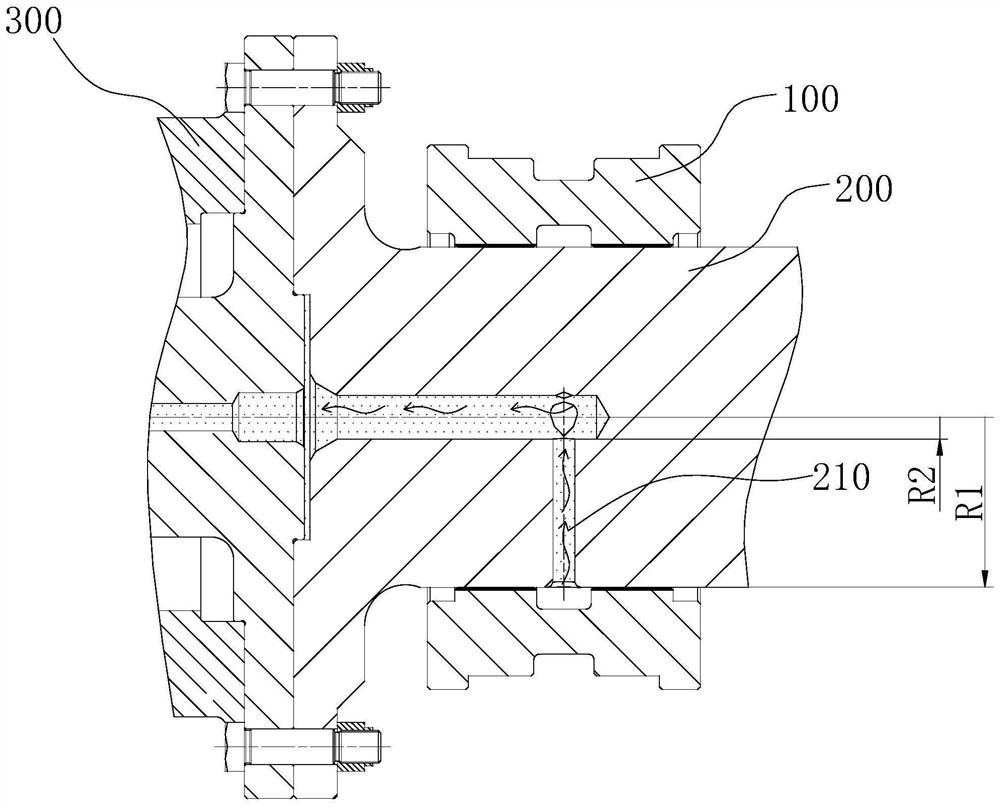

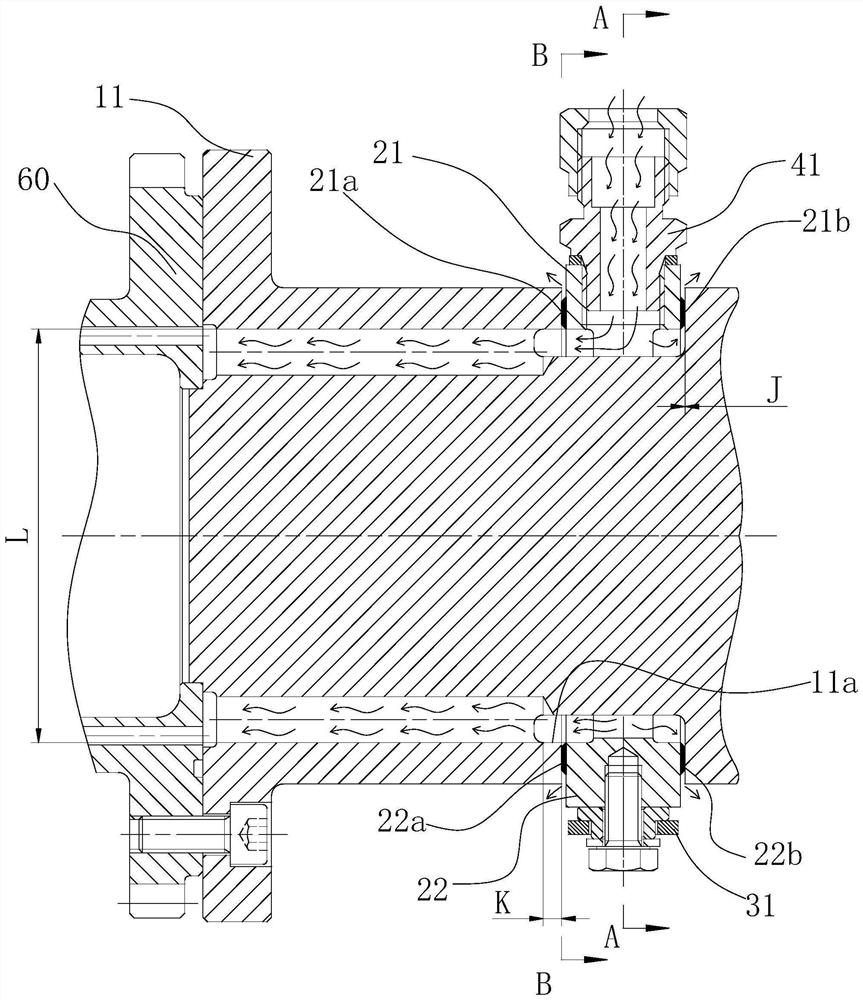

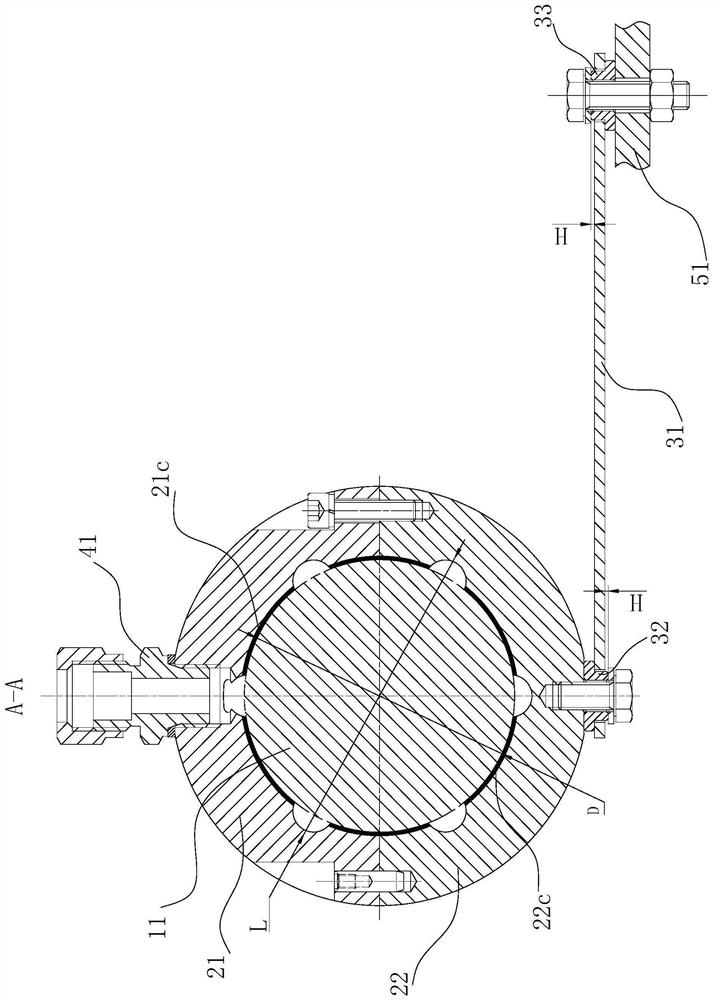

[0022] figure 2 Among them, the oil supply slip ring includes two parts, the slip ring assembly and the slip ring installation groove, the slip ring installation groove is located on the connecting shaft 11 of the synchronous automatic clutch 60, and the remaining parts form the slip ring assembly. A ring groove and an axial oil hole are provided on the connecting shaft (11) of the clutch, and lubricating oil is supplied from the oil supply joint 41, flows through the lubricating oil hole on the connecting shaft 11, and finally enters the synchronous automatic clutch 60. In the working state, the synchronous automatic clutch 60 and its connecting shaft 11 rotate at a high speed, which will cause the radial flow of the fluid on the connecting shaft 11 to become difficult. In order to ensure that the lubricating oil is more effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com