Unstable hedging flame burner structure with height controllable speed boundary

A speed boundary and flame combustion technology, applied in the direction of burner, burner, burner cooling, etc., can solve the problem of unable to form a controllable unsteady flame, achieve uniform speed distribution, increase hedging speed, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

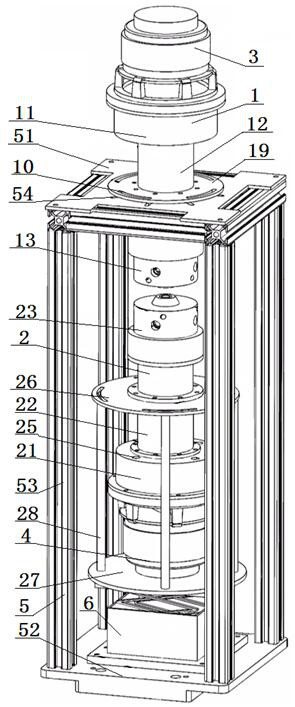

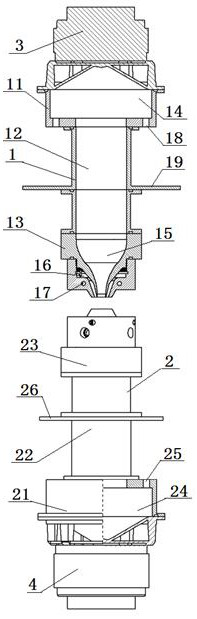

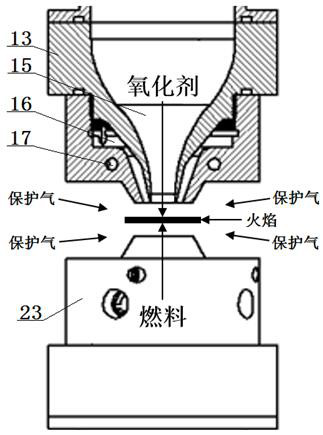

[0050] An unsteady opposed flame burner structure with a highly controllable velocity boundary, the burner includes: an oxidant injector 1 and a gaseous fuel injector 2 arranged oppositely up and down, the oxidizing gas injector 1 and the gaseous fuel The injector 2 is arranged coaxially along the vertical direction, the injection ports of the oxidizing gas injector 1 and the gaseous fuel injector 2 are arranged oppositely up and down, and the top of the oxidizing gas injector 1 is provided with a gas vibration generator 3 at the oxidant end , the oscillation generating end of the gas vibration generator 3 at the oxidant end is set facing the gas injection channel of the oxidizing gas injector 1, the gas vibration generator 4 at the fuel end is arranged at the bottom of the gaseous fuel injector 2, and the gas vibration generator 4 at the fuel end is arranged at the bottom of the gaseous fuel injector 2. The vibration generating end of the vibration generator 4 is set facing th...

Embodiment 2

[0053] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0054]The burner also includes: a burner bracket 5, the burner bracket 5 is a cuboid metal frame structure, and the burner bracket 5 is fixedly connected to the middle part of the oxidant injector 1 through an upper fixing plate 51 provided on the top thereof, so that The bottom of the burner bracket 5 is provided with a lower fixing plate 52, the four corners of the lower fixing plate 52 are fixedly connected with the four corners of the upper fixing plate 51 through four columns 53, and the middle part of the top surface of the lower fixing plate 52 is fixed with a height Regulator 6, the lifting adjustment end at the top of the height regulator 6 is fixedly connected to the bottom of the gaseous fuel injector 2; the outer middle section of the oxidant end steady flow pipeline 12 is provided with an oxidant end fixing plate 19, and the oxidant end is fixed The disc 19 is connected with the up...

Embodiment 3

[0056] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0057] The steady flow pipeline 12 at the oxidant end is set through the through hole in the middle of the upper fixing plate 51, and the upper fixing plate 51 is provided with a plurality of oblong holes 54 arranged radially along the middle through hole. A plurality of arc-shaped holes 10 are evenly distributed on the circumference concentric with the oxidizer end steady flow pipeline 12, and the oxidant end fixing plate 19 is fixed on the upper fixing plate 51 by bolts, and the bolts pass through the arc holes in turn After 10 oblong holes 54 are connected with nuts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com