Industrial automation maintenance method and system based on edge and cloud fusion

An industrial automation and maintenance system technology, applied in the field of industrial automation maintenance methods and systems, can solve the problems of inconvenient operation, inability to scale operation, and high maintenance costs, and achieve the goal of widening the control range, realizing online updates, and enhancing satisfaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

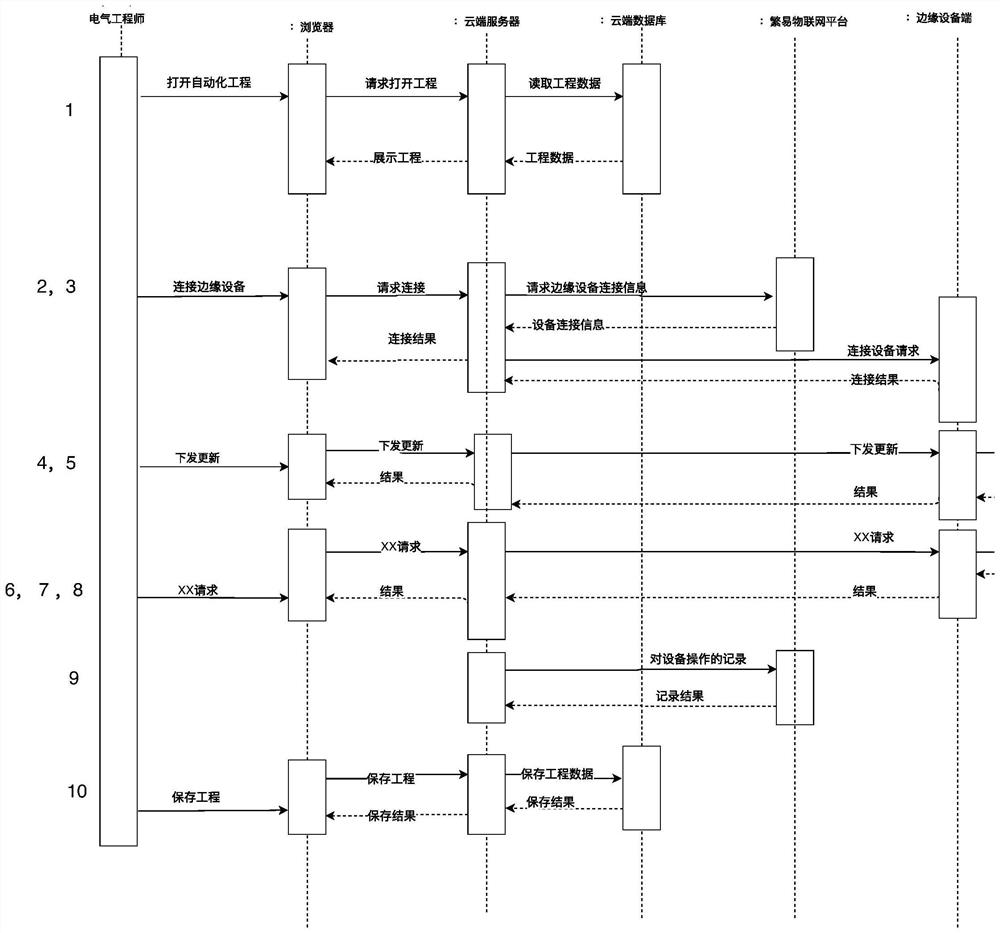

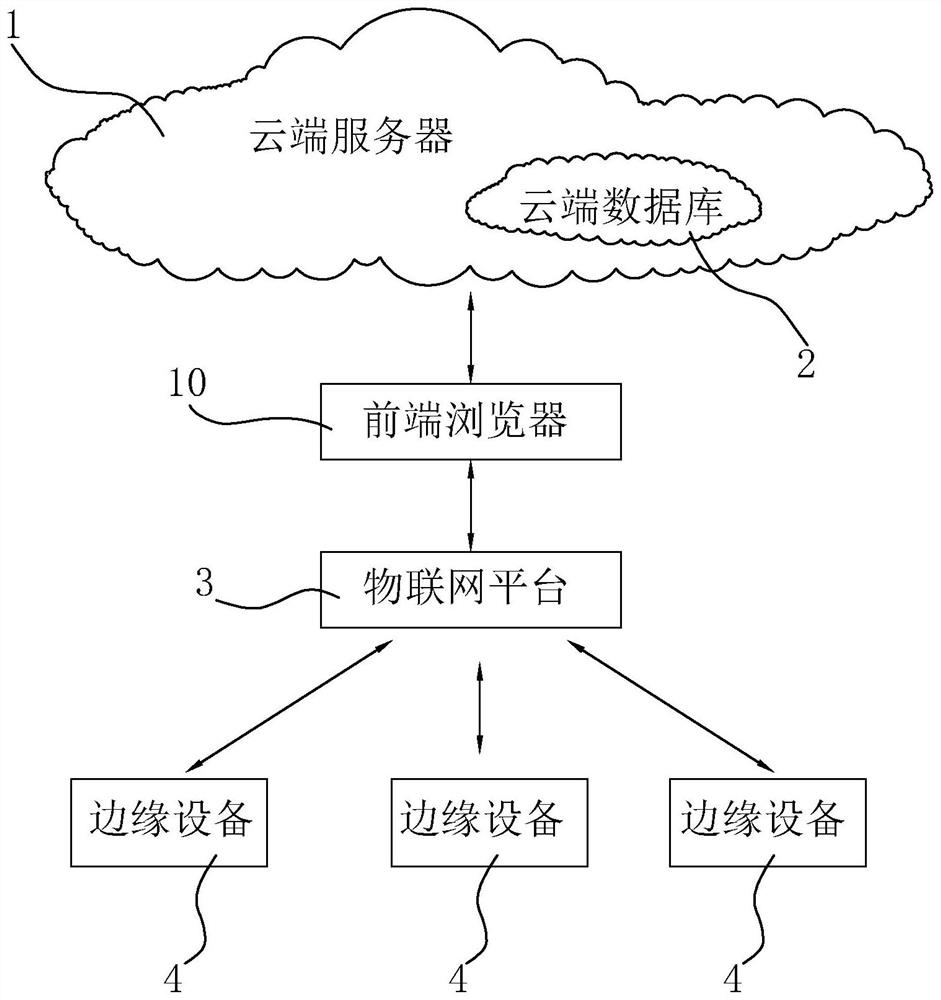

[0040] This application discloses an industrial automation maintenance method and system for the integration of edge and cloud. The integrated development environment of the cloud is displayed to the electrical engineer through the human-machine interface interface. After the electrical engineer changes the configuration of the corresponding automation project or edge equipment, he uses the Internet of Things The platform 3 locates the corresponding edge device 4, sends a request to the equipment installed on the edge device 4, and the processing program on the edge device 4 receives the request, performs corresponding processing on the device and feeds back the processing result to the cloud server 1.

[0041] Specifically, a browser-based cloud development environment needs to be set up before maintenance, and the engineering data is stored in the cloud database 2, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com