Plate texture Schmidt factor calculation method and device and storage medium

A calculation method and texture technology, applied in the calculation method of Schmidt factor of plate texture under different stress directions, equipment and storage media, can solve the problem of less consideration of the influence of plate texture, and reduce the calculation work Quantity, improving calculation efficiency, and high accuracy of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment discloses a method for calculating the Schmidt factor of a plate texture under different stress directions, and the method includes the following steps:

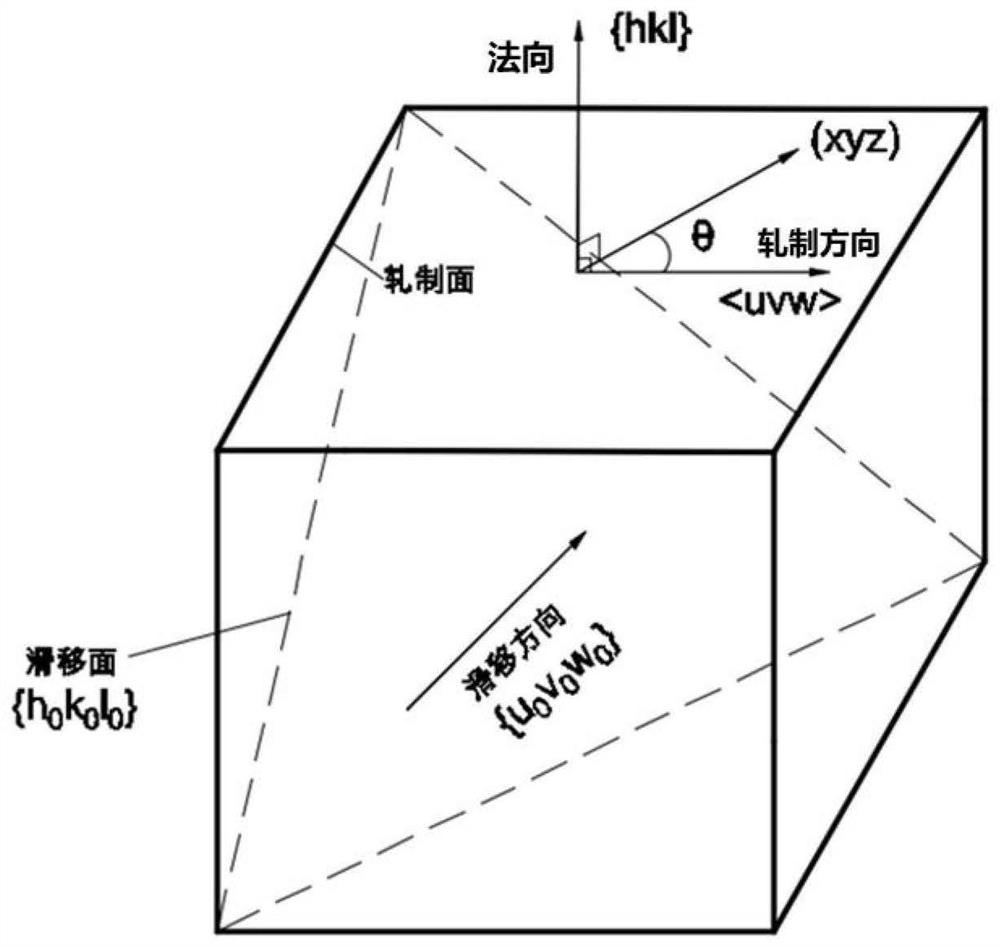

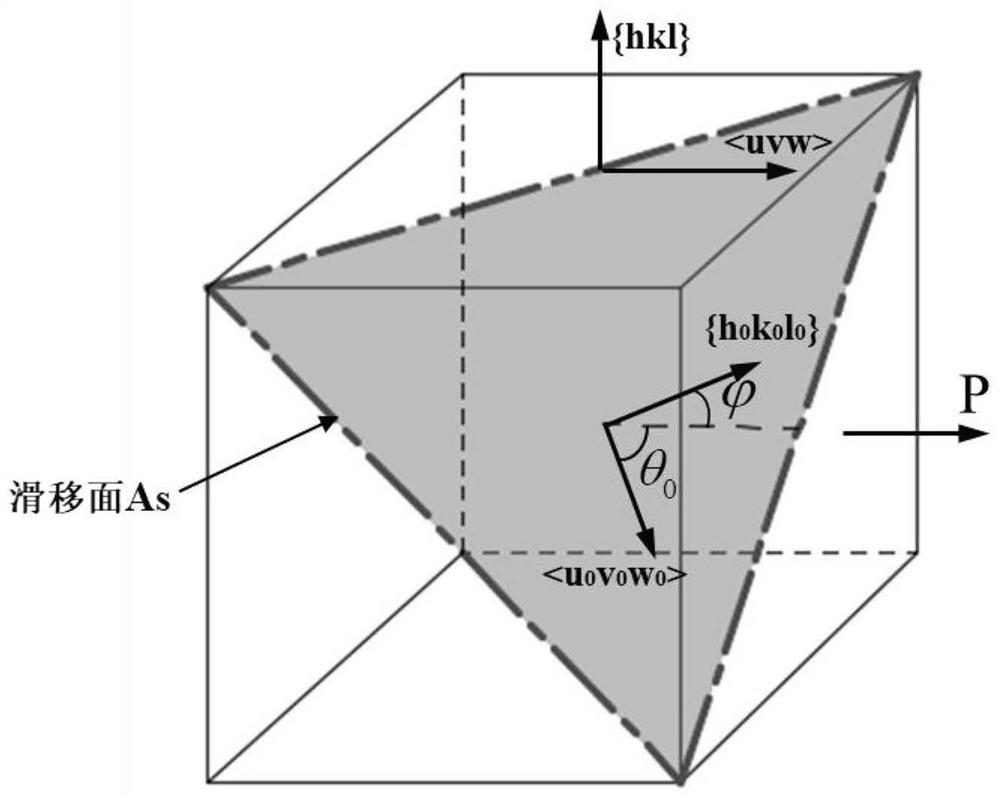

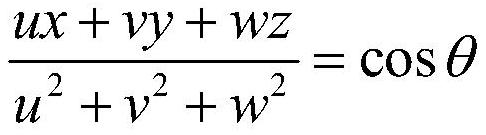

[0026] Step 1. Determine the plate texture type inside the face-centered cubic aluminum alloy of the rolled plate by EBSD test, expressed as {hkl} by Miller index , where {hkl} represents the rolling surface, Represents the rolling direction; let the direction vector of the external force be (x, y, z), the angle between the external force and the rolling direction is θ, and θ satisfies the condition: 0≤θ≤90°, and the direction of the external force is determined by the equation The values of x, y, z of the vector, the equation system is:

[0027] hx+ky+lz=0

[0028]

[0029] x 2 +y 2 +z 2 = u 2 +v 2 +w 2

[0030] Specifically, take the {001} texture of the face-centered cubic aluminum alloy as an example to find the Schmidt factor under the 30° force direction. Through ...

Embodiment 2

[0111] This embodiment discloses a computing device, including: one or more processors; memory; and one or more programs, wherein one or more programs are stored in the memory and configured to be executed by the one or more processors Execution, one or more programs include instructions for calculating the Schmidt factor of the plate texture in different directions of force, the method includes steps:

[0112] Step 1. Determine the plate texture type inside the rolled plate by EBSD test, expressed as {hkl} by Miller index , where {hkl} represents the rolling surface, Represents the rolling direction; let the direction vector of the external force be (x, y, z), the angle between the external force and the rolling direction is θ, and θ satisfies the condition: 0≤θ≤90°, and the direction of the external force is determined by the equation The values of x, y, z of the vector, the equation system is:

[0113] hx+ky+lz=0

[0114]

[0115] x 2 +y 2 +z 2 = u ...

Embodiment 3

[0121] A computer-readable storage medium storing one or more programs, wherein the one or more programs include instructions, the instructions are adapted to be loaded from the memory and execute the method for calculating the Schmidt factor of the plate texture under different force directions, The method includes the steps of:

[0122] Step 1. Determine the plate texture type inside the rolled plate by EBSD test, expressed as {hkl} by Miller index , where {hkl} represents the rolling surface, Represents the rolling direction; let the direction vector of the external force be (x, y, z), the angle between the external force and the rolling direction is θ, and θ satisfies the condition: 0≤θ≤90°, and the direction of the external force is determined by the equation The values of x, y, z of the vector, the equation system is:

[0123] hx+ky+lz=0

[0124]

[0125] x 2 +y 2 +z 2 = u 2 +v 2 +w 2

[0126] Step 2. According to the known slip system {...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com