Flame-retardant cable and cable flame-retardant layer forming process

A technology of flame-retardant cables and flame-retardant layers, which is applied in the direction of insulated cables, flexible cables, and cable/conductor manufacturing, and can solve the problems of not considering the flexibility of flame-retardant materials, increasing the length of cables, and increasing the cost of use. , to achieve a good flame retardant effect, reduce space occupation, and save the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

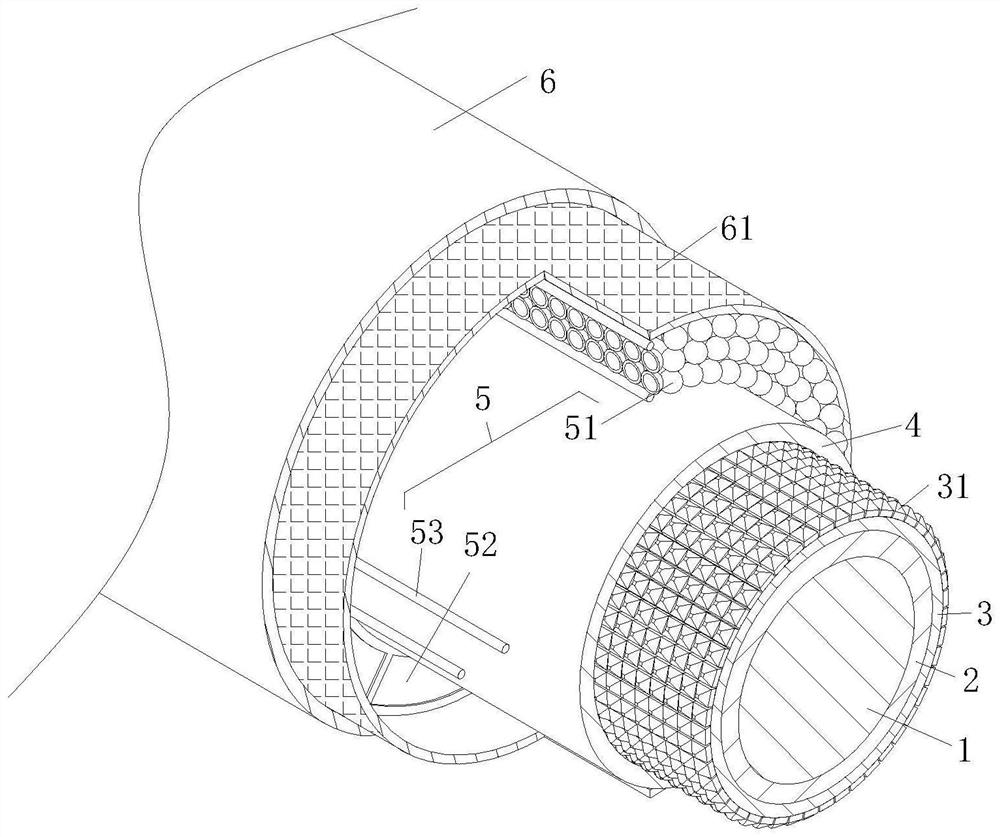

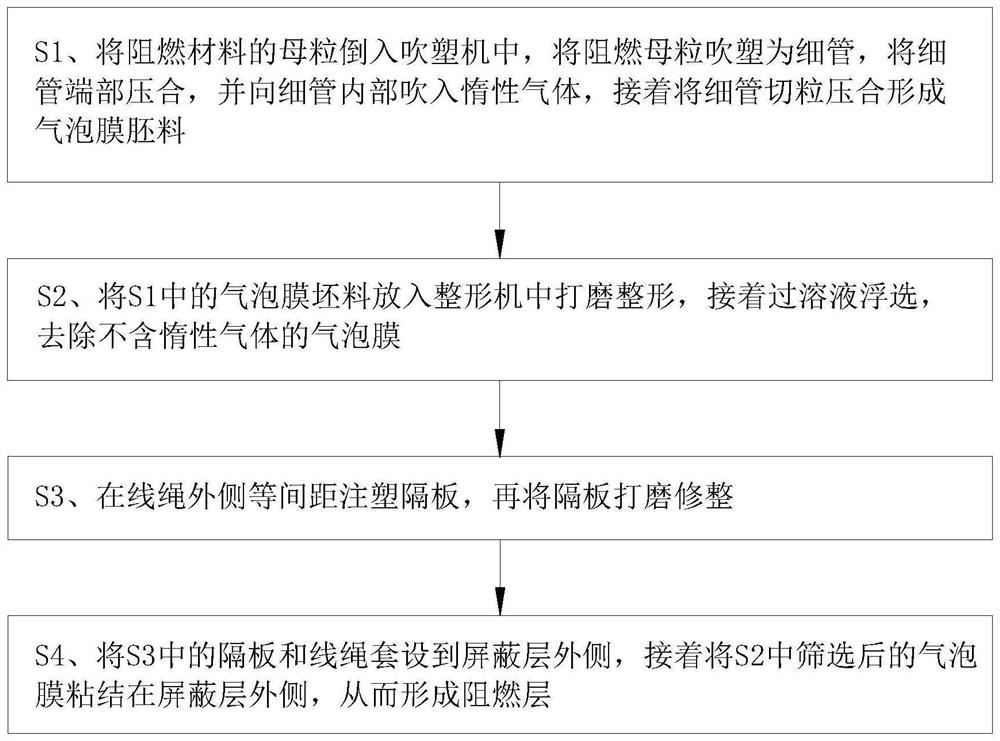

[0032] As an embodiment of the present invention, a mesh rope core 61 is provided inside the cladding layer 6, and the mesh rope core 61 is made of a refractory material, and the hole diameter of the mesh rope core 61 is smaller than the diameter of the bubble film 51; During work, by setting the mesh rope core 61, when the covering layer 6 is damaged by external force, the mesh rope core 61 connects the broken covering layer 6, further ensuring the protective effect of the covering layer 6, and the flame burns When the covering layer 6 is easy to melt and condense, it is not easy to drip, so that the air bubble film 51 is stabilized. When the covering layer 6 is burned and damaged, because the aperture of the mesh rope core 61 is smaller than the diameter of the air bubble film 51, the air bubble film 51 will be further strengthened. 51 to limit the position to prevent the air bubble film 51 from being bonded tightly and falling off, which will affect the flame retardant effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com