High-low voltage power distribution equipment with energy-saving performance

A power distribution equipment, energy-saving technology, applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve the problem that power distribution equipment cannot effectively save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

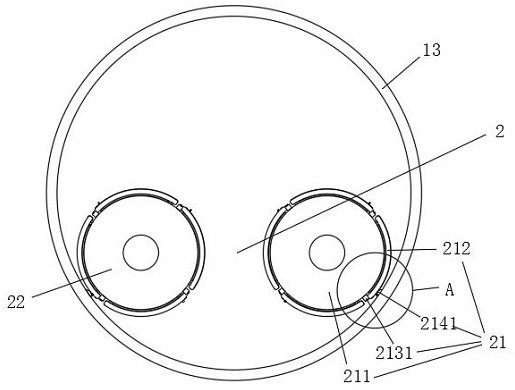

[0041] In a typical implementation, such as figure 1 , Figure 9 , Figure 11 As shown, a high and low voltage energy-saving power distribution equipment includes a housing 1, and an air inlet 11 and an air outlet 12 are opened on the housing 1, and electrostatic adsorption devices are arranged at the air inlet 11 and the air outlet 12. 2.

[0042] The outside air flows into the housing 1 through the air inlet 11 , blows to the power distribution components inside the housing 1 , and then is discharged through the air outlet 12 . When the airflow passes through the corresponding electrostatic adsorption device 2, it is purified and dust-removed by the electrostatic adsorption device 2.

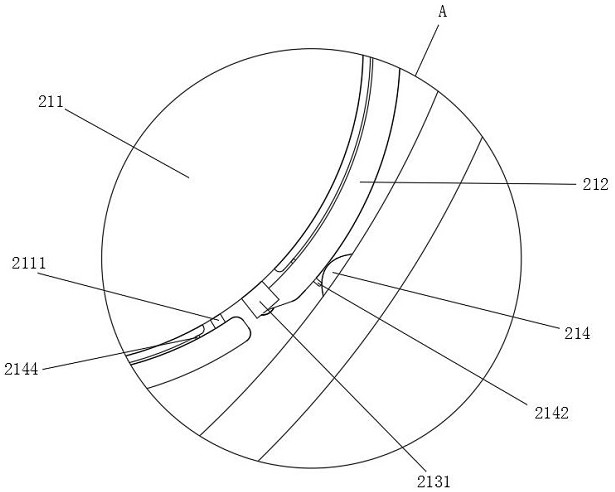

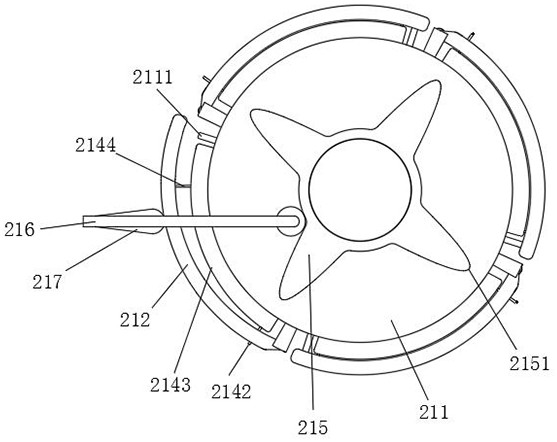

[0043] The electrostatic adsorption device 2 includes a positive pole piece 21 and a negative pole piece 22 . The positive pole piece 21 and the negative pole piece 22 are arranged opposite to each other. The air flow passes through the channel between the positive pole piece 21 and the neg...

Embodiment 2

[0078] Further, such as Figure 7 , Figure 8 As shown, a roller 2161 is rolled on the moving rod 216, and the roller 2161 is offset against the transmission plate 215, so that the relative movement between the roller 2161 and the transmission plate 215 is better, and the influence of friction on the relative movement is reduced.

Embodiment 3

[0080] The difference between this embodiment and the above-mentioned embodiment is that: Figure 11 As shown, a dust removal port 14 is provided on the side wall of the processing cylinder 13, and the dust removal port 14 is opposite to the position where the dust collection plate 212 is opened. When the dust collection plate 212 is opened, the dust on the dust collection plate 212 can be removed from the Mouth 14 falls.

[0081] Further, a non-return side plate 15 is fixedly installed on the inner wall of the processing cylinder 13, and the non-return side plate 15 is opposite to the dust removal port 14, and is blocked by the non-return side plate 15 to prevent the air flow from flowing back into the processing cylinder from the dust removal port 14 13 interior.

[0082] Such as Figure 9 As shown, further, the outer wall of the processing cylinder 13 is fixedly equipped with a discharge box 16, the dust removal block 217, the second elastic member 218, and the guide fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com