Circular plate type vibration energy collector based on MFC

A vibration energy harvesting, circular plate technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. , the collector is easy to crack, etc., to achieve the effect of high electromechanical conversion efficiency, convenient application and low rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The invention relates to an MFC-based disc type vibration energy collector, which mainly adopts a piezoelectric conversion method to convert vibrational mechanical energy into electric energy for output. Piezoelectric conversion has the advantages of simple structure, high power density and high output voltage. Therefore, it is a better way to use piezoelectric effect to harvest vibration energy.

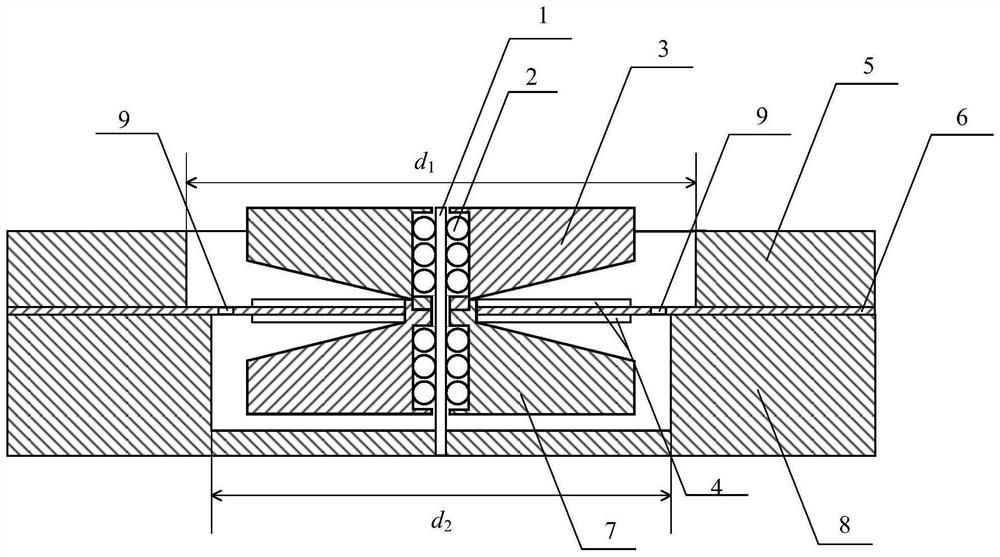

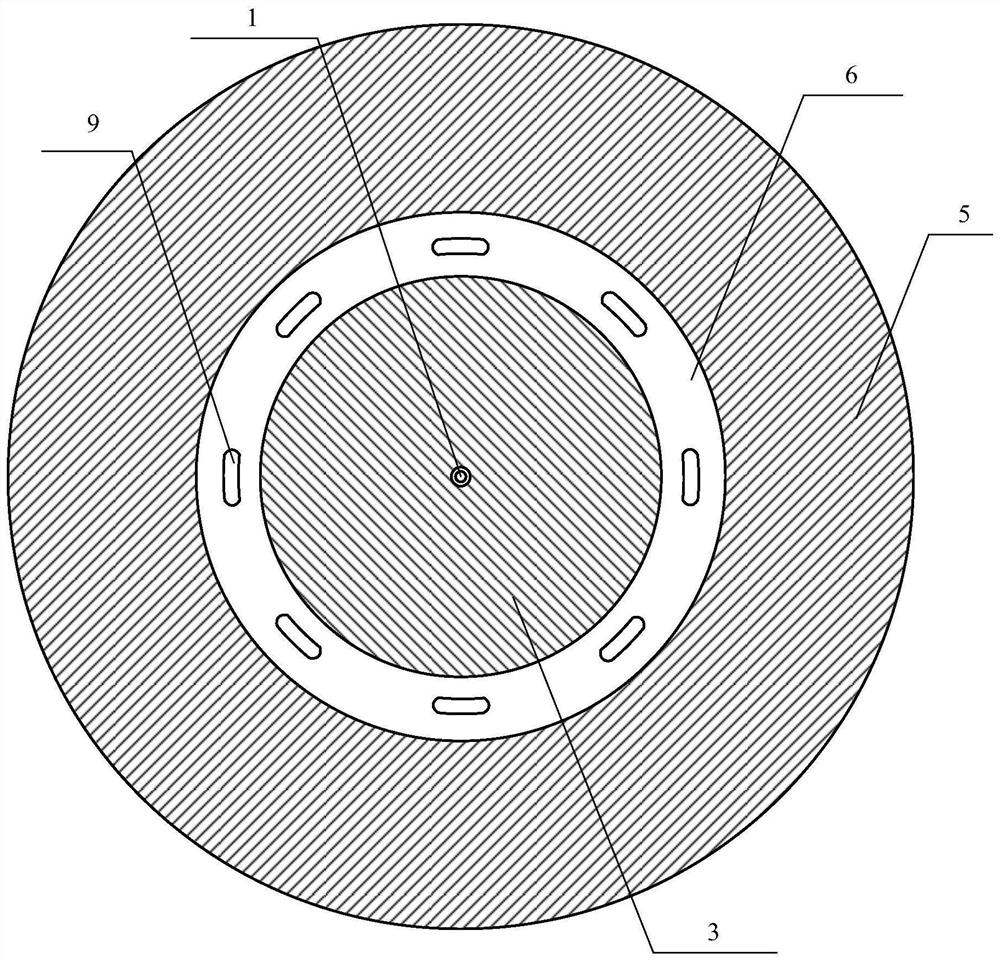

[0028] Specifically, such as figure 1 , figure 2 As shown, the disc type vibration energy harvester based on the piezoelectric ceramic fiber sheet MFC (Macro FiberComposite) of the present invention comprises a laminated disc, a pressure ring 5, a base 8, an upper central mass 3, a lower central mass 7 and a guide Column 1. The base 8 is a disc-shaped base, and the central position of the disc-shaped base is provided with a downwardly recessed cylindrical groove, and the guide post 1 is vertically fixed on the top of the central position of the groove of the base 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com