Dry powder disinfectant for preventing cow mastitis and preparation method thereof

A dairy cow mastitis and disinfectant technology, applied in the direction of disinfectant, botany equipment and method, fungicide, etc., can solve the problems of economic losses in the breeding industry, dairy cows, etc., and achieve the prevention of dairy cow mastitis, uniform mixing, and mixing Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

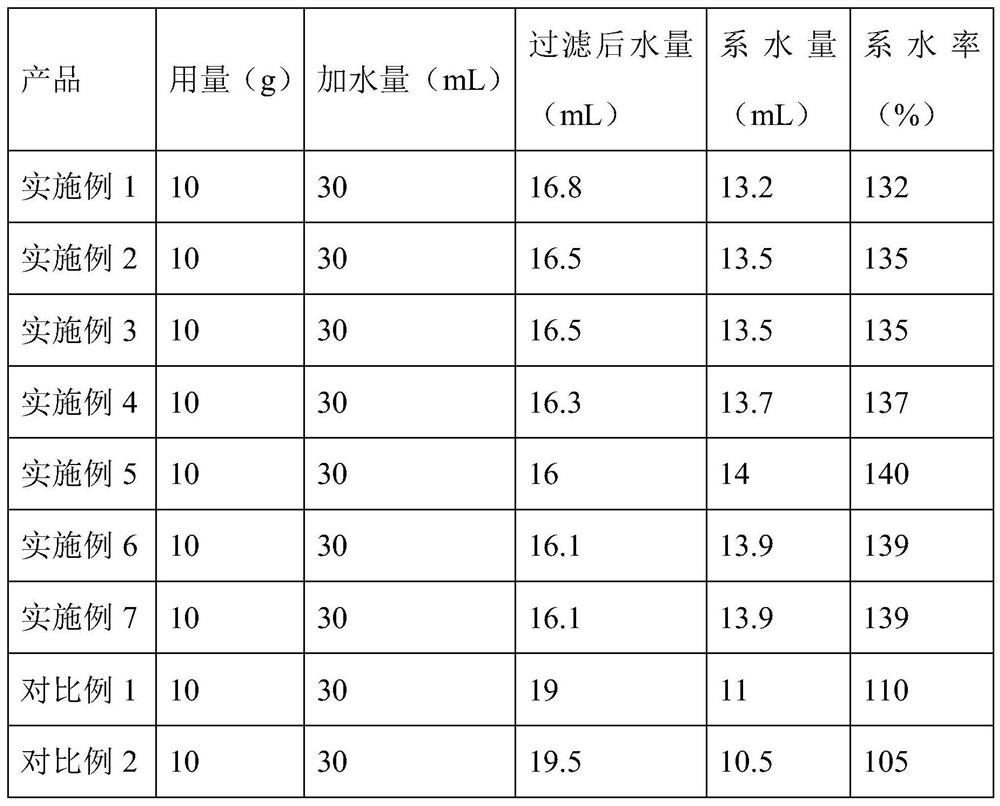

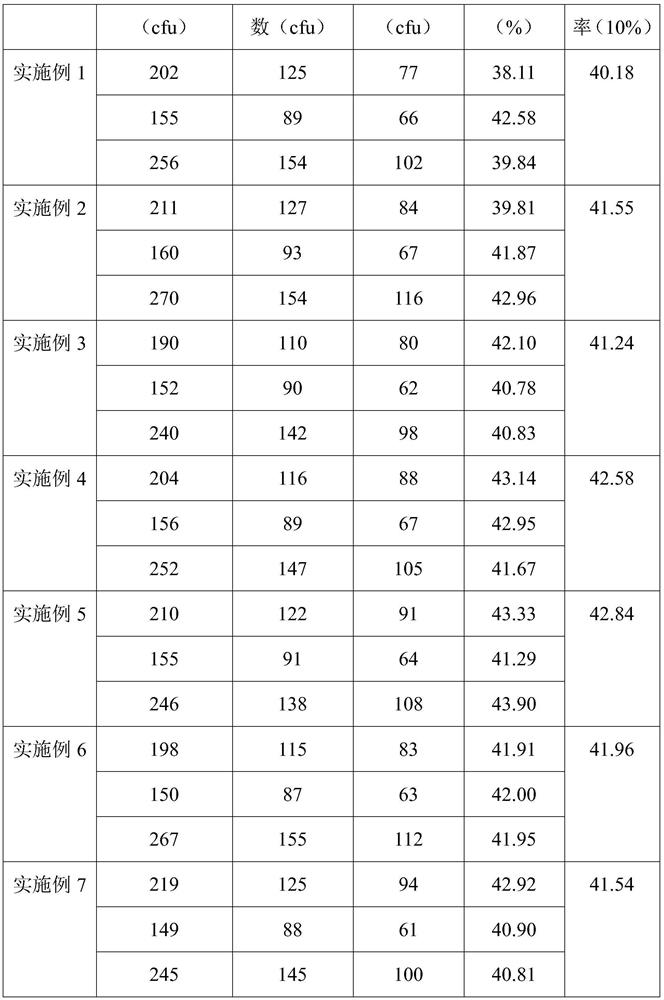

Examples

Embodiment 1

[0044] A preparation method of a dry powder disinfectant for preventing dairy cow mastitis, comprising the following preparation steps:

[0045] Weigh each raw material, sieve after weighing, and reserve each raw material that meets the mesh number of 300-400, and grind the raw material that does not meet the particle size requirement, and grind it into 300-400 mesh powder for future use;

[0046] First add 0.5% preservatives, 5% boric acid, 5% antifungal agents and 1% functional additives to 20% of the total weight of diatomaceous earth, and place the above-mentioned raw materials in three-dimensional mixing In the machine, mix and stir for 8 minutes to obtain material a;

[0047] Then add 20% of the disinfection component and 30% of the total weight of diatomaceous earth into material a, place it in a three-dimensional mixer, and mix and stir for 8 minutes to obtain material b;

[0048] Add the remaining amount of diatomaceous earth to material b, then put the above raw mat...

Embodiment 2

[0050] A preparation method of a dry powder disinfectant for preventing dairy cow mastitis, comprising the following preparation steps:

[0051] Weigh each raw material, sieve after weighing, and reserve each raw material that meets the mesh number of 300-400, and grind the raw material that does not meet the particle size requirement, and grind it into 300-400 mesh powder for future use;

[0052] First add 0.5% preservatives, 5% boric acid, 5% antifungal agents and 1% functional additives into 25% of the total weight of diatomite, and place the above-mentioned raw materials in a three-dimensional In the mixer, mix and stir for 10 minutes to obtain material a;

[0053] Then add 20% of the disinfection component and 35% of the total weight of diatomaceous earth into material a, place it in a three-dimensional mixer, and mix and stir for 10 minutes to obtain material b;

[0054] Add the remaining amount of diatomaceous earth to material b, then put the above-mentioned raw mater...

Embodiment 3

[0056]A preparation method of a dry powder disinfectant for preventing dairy cow mastitis, comprising the following preparation steps:

[0057] Weigh each raw material, sieve after weighing, and reserve each raw material that meets the mesh number of 300-400, and grind the raw material that does not meet the particle size requirement, and grind it into 300-400 mesh powder for future use;

[0058] First add 0.5% preservatives, 5% boric acid, 5% antifungal agents and 1% functional additives into 30% of the total weight of diatomaceous earth, and place the above-mentioned raw materials in three-dimensional mixing In the machine, mix and stir for 12 minutes to obtain material a;

[0059] Then add 20% of the weighed disinfection components and 40% of the total weight of diatomaceous earth into material a, place in a three-dimensional mixer, mix and stir for 12 minutes, and obtain material b;

[0060] Add the remaining amount of diatomaceous earth to material b, then put the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com