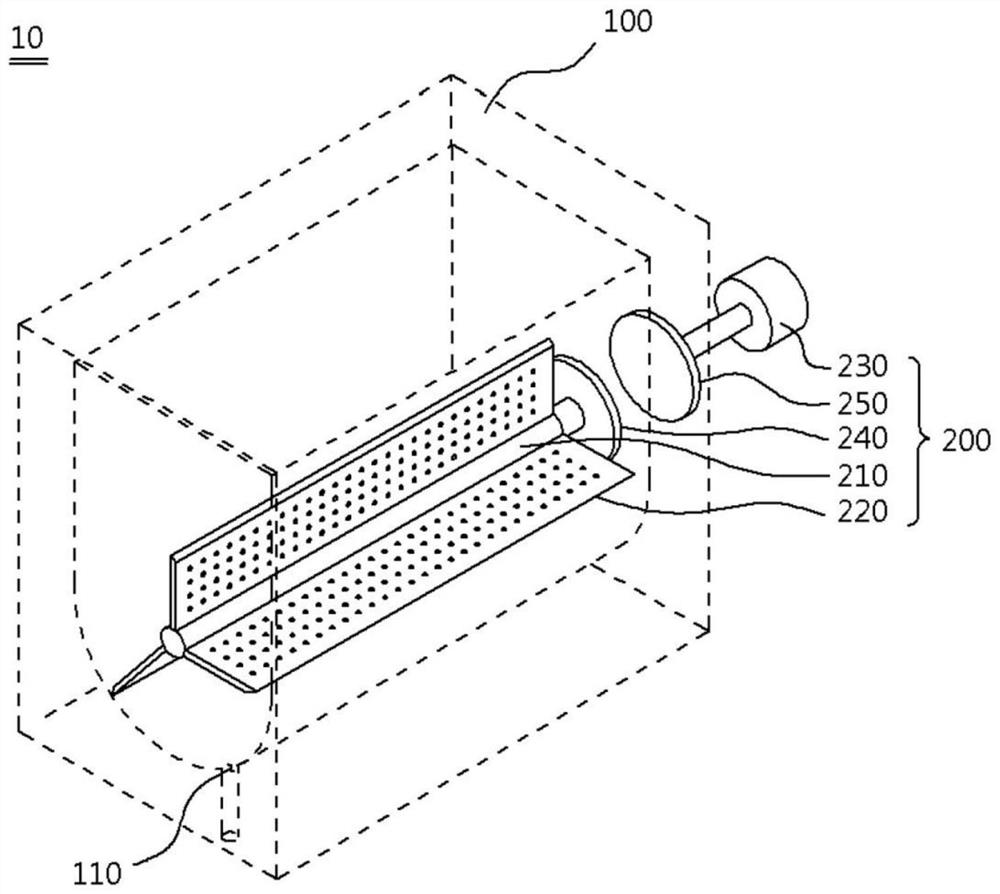

Agitator-containing ink tank for inkjet printers with improved dispersion stability

A technology for inkjet printers and ink storage tanks, applied in the field of storage tanks, can solve problems such as difficult dispersibility, bad and difficult dispersibility of conventional strip agitators, and achieve the effect of enhancing the agitation effect and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

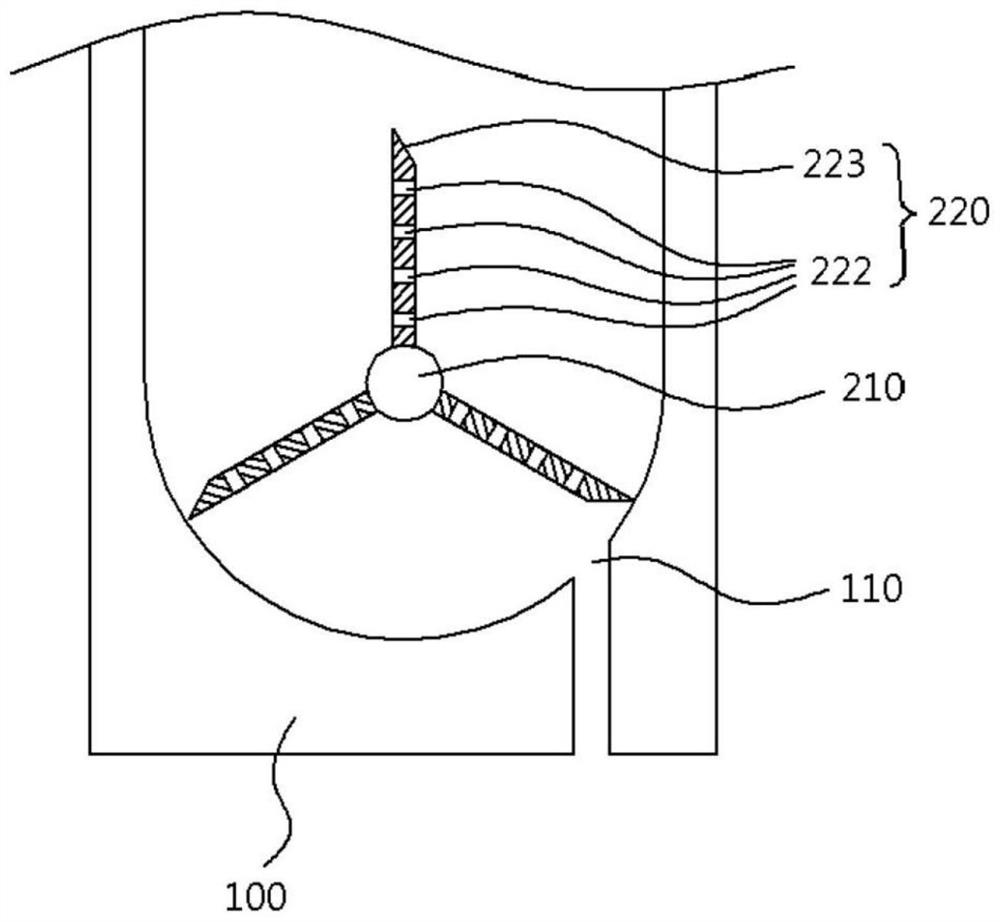

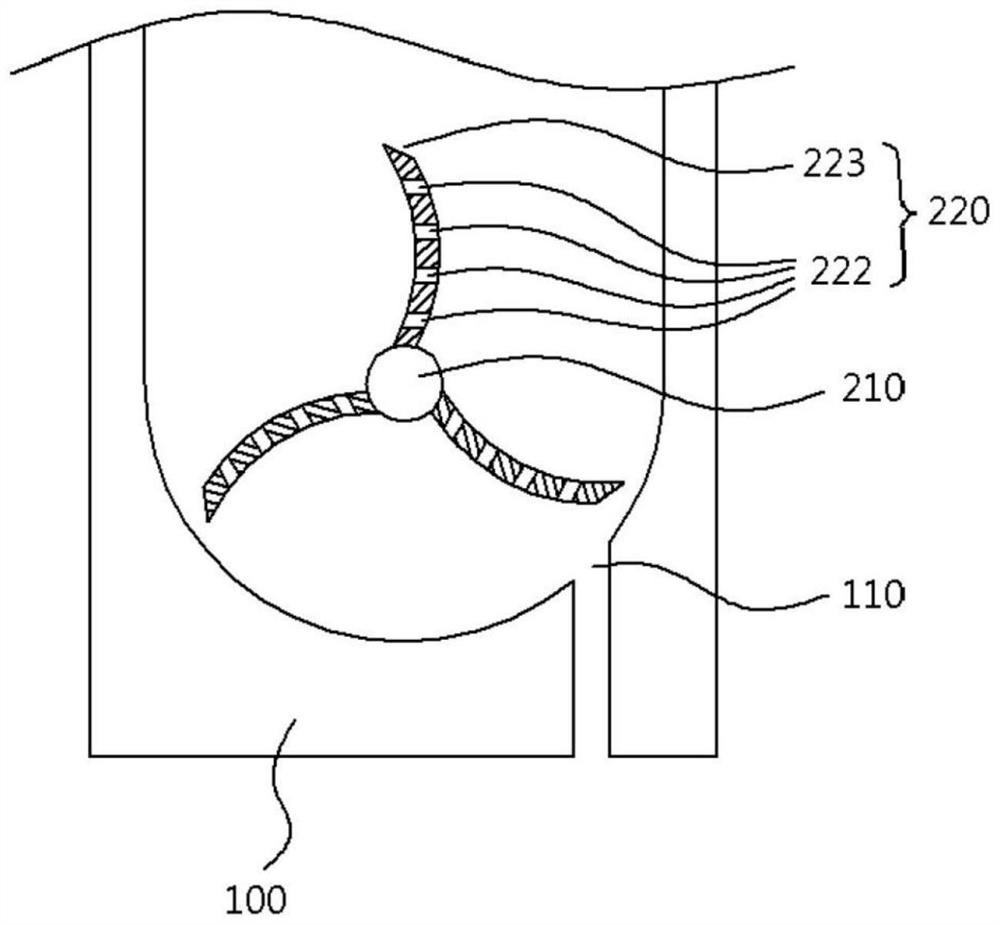

[0039] Embodiments according to the present disclosure will be described in detail with reference to the drawings.

[0040] However, the embodiments of the present disclosure can be changed into numerous other forms, and the scope of the present disclosure is not limited to the embodiments described below. The shapes, dimensions, etc. of elements in the drawings may be exaggerated for clearer explanation, and the same elements are denoted by the same reference numerals in the drawings.

[0041] Furthermore, throughout the specification, when it is expressed that one part is "connected" to another part, it includes not only the case of "direct connection" but also the case of "electrical connection" between the two parts with another part. . Also, when it is expressed that a component “includes” or “has” a member, it should be understood that unless otherwise specified, this does not exclude other members, but may also include or have other members.

[0042] In addition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com