Sintering-free porous ceramsite and preparation process thereof

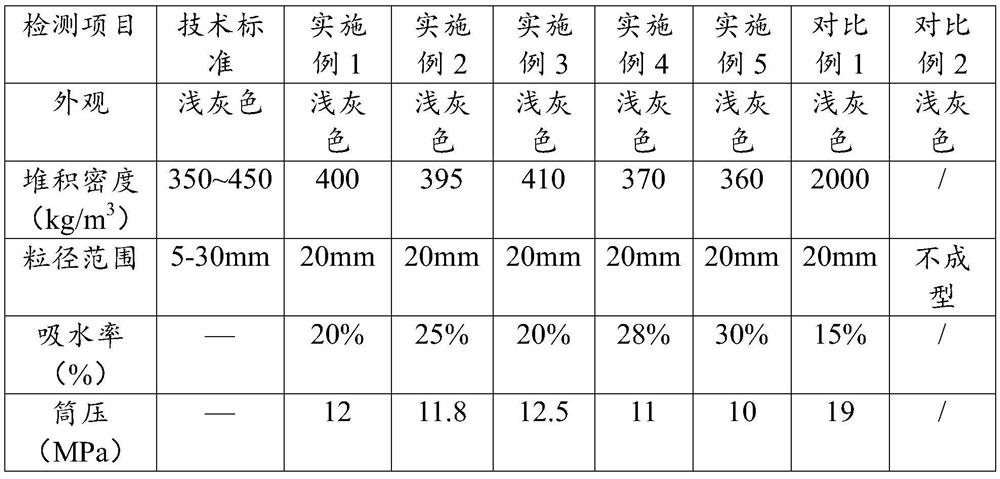

A preparation process and a technology for porous ceramics, which are applied in the field of sintering-free porous ceramics and their preparation, can solve the problems of low density, high porosity, and difficulty in utilizing industrial waste, and achieve excellent performance, improved porosity, and improved closure. The effect of porosity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

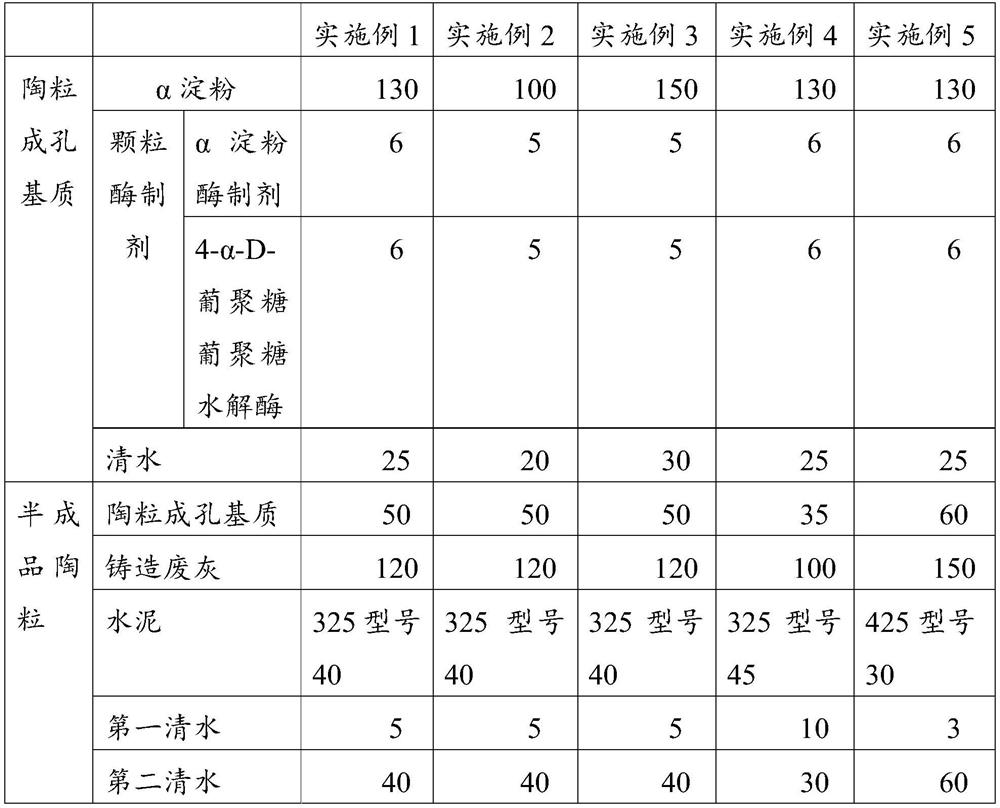

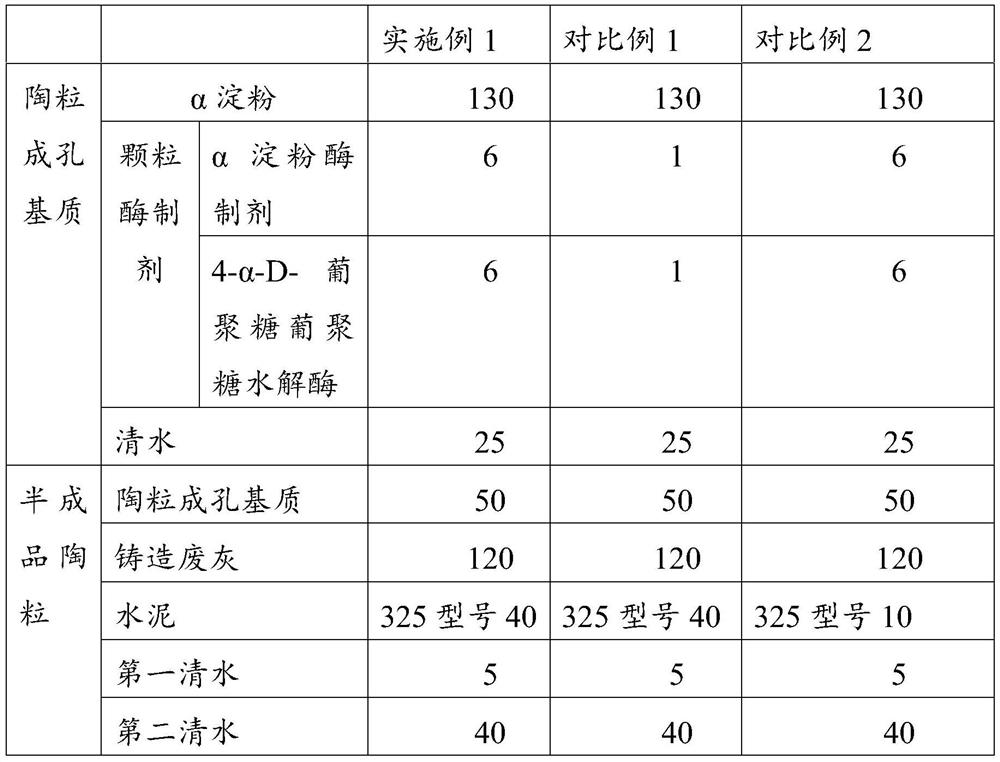

Embodiment 1

[0038] The embodiment of the present invention provides a preparation process of non-sintering porous ceramsite, comprising the following steps:

[0039] S11: Preparation of ceramsite pore-forming matrix

[0040] S111, preparation of raw materials, α-starch 130kg, granule enzyme preparation 12kg (wherein, α-amylase preparation and 4-α-D-glucan glucan hydrolase are half and half, respectively 6kg, and the particle diameter of granule enzyme preparation is 500 mesh-1000 mesh), clean water 25kg.

[0041] S112, mix starch and granular enzyme preparations and add them to the granulator for granulation. The inclination angle of the granulation pan is 25°, and the rotation frequency is 40Hz. During the granulation process, add clear water to the materials in the granulation pan in the form of atomization , the particle size of the granulation is 3-8mm, the control range of the water content is 15%-20%, and the ceramsite pore-forming matrix is prepared.

[0042] S12: Preparation o...

Embodiment 2

[0052] The difference from Example 1 is that in the preparation of the ceramsite pore-forming matrix in step S11, the following raw materials are used:

[0053] α-starch 100kg, granule enzyme preparation 10kg (wherein, α-amylase preparation and 4-α-D-glucan glucan hydrolase are half and half, respectively 5kg, and the particle diameter of granule enzyme preparation is (500 mesh-1000 mesh ), clean water 20kg.

Embodiment 3

[0055] The difference from Example 1 is that in the preparation of step S11 ceramsite pore-forming matrix, the following raw materials are used: 150 kg of α-starch, 10 kg of granular enzyme preparation (wherein, α-amylase preparation and 4-α-D-glucan The glucan hydrolase is half and half, respectively 5kg, the particle size of the granzyme preparation is (500 mesh-1000 mesh), and clear water 30kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com