Rotary lifting mechanism driven by straight stroke actuator

A lifting mechanism and straight stroke technology, applied in the direction of engine components, shaking/oscillating/vibrating mixers, mixers, etc., can solve the problems of complex structure of air motors, high cost of air motors, and easy failures, etc., to achieve simple structure, High rotational torque and friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

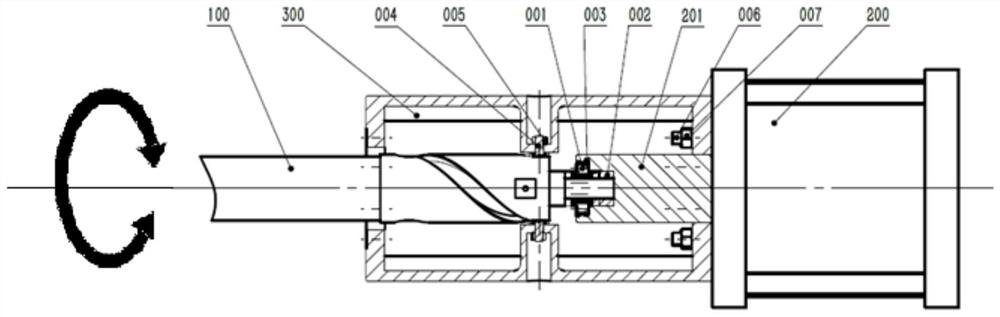

[0023] refer to figure 1 , shows a schematic structural view of a rotary lifting mechanism driven by a linear actuator provided in an embodiment of the present invention.

[0024] Such as figure 1 As shown, the rotary lifting mechanism driven by the linear stroke actuator provided by the embodiment of the present invention may include: an actuator member 100, a needle roller with a flange and a double-direction thrust cylindrical roller bearing 001, a lock nut 002, a bolt 003, Straight stroke actuator 200, straight stroke push rod 201, bracket barrel 300, bolt type roller needle bearing 004, nut 005, stud 006, nut 007.

[0025] The bracket cylinder 300 and the linear stroke actuator 200t are fixed on the same axis. The bolt type roller needle roller bearing 004 is assembled on the bracket cylinder 300 through the nut 005. Cooperate.

[0026] The combined needle roller and bidirectional thrust cylindrical roller bearing 001 with flange is a ZARF type standard bearing, which ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap