Still kettle waste heat environment-friendly recovery equipment for autoclaved aerated concrete slab production

A concrete slab, autoclaved aeration technology, applied in lighting and heating equipment, heat exchange equipment, heat exchangers, etc., can solve problems such as waste of thermal energy resources, and achieve the effect of avoiding burns, improving utilization, and protecting workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

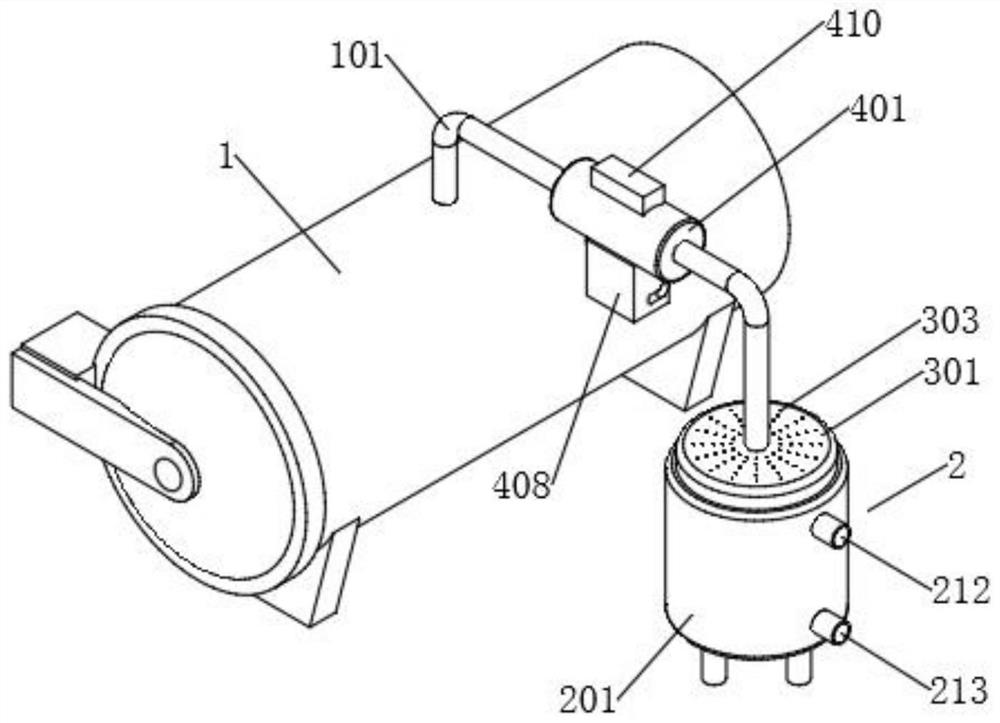

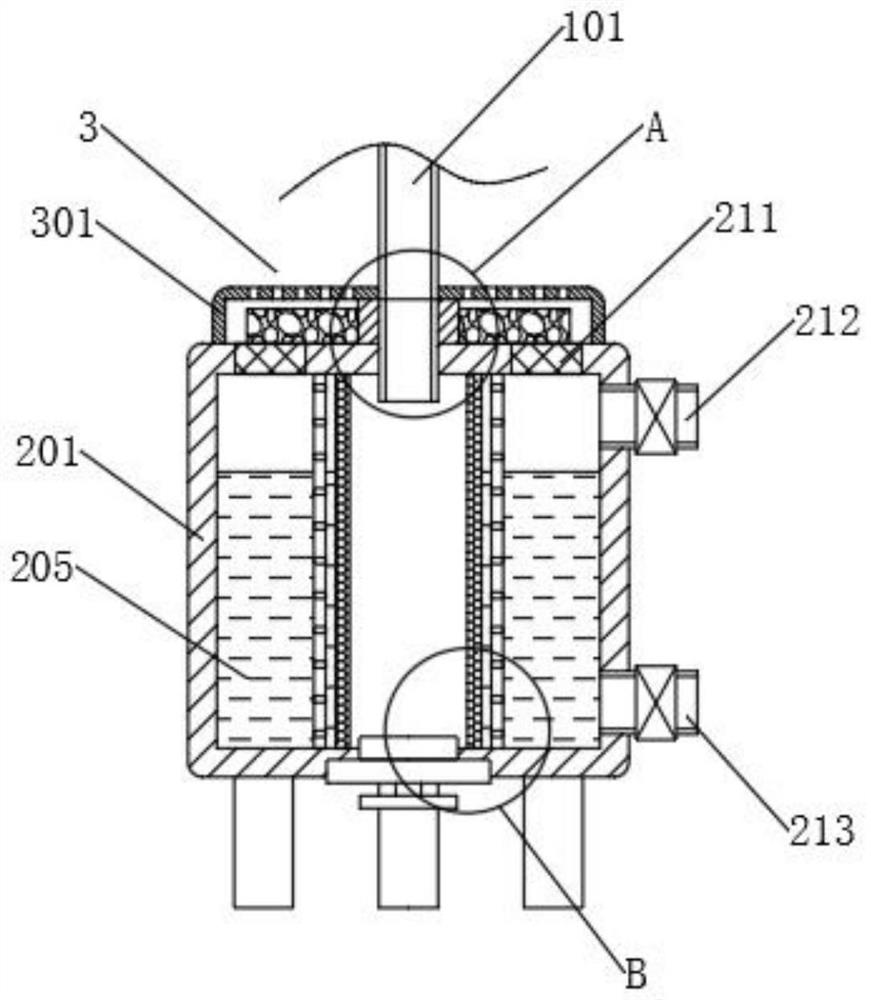

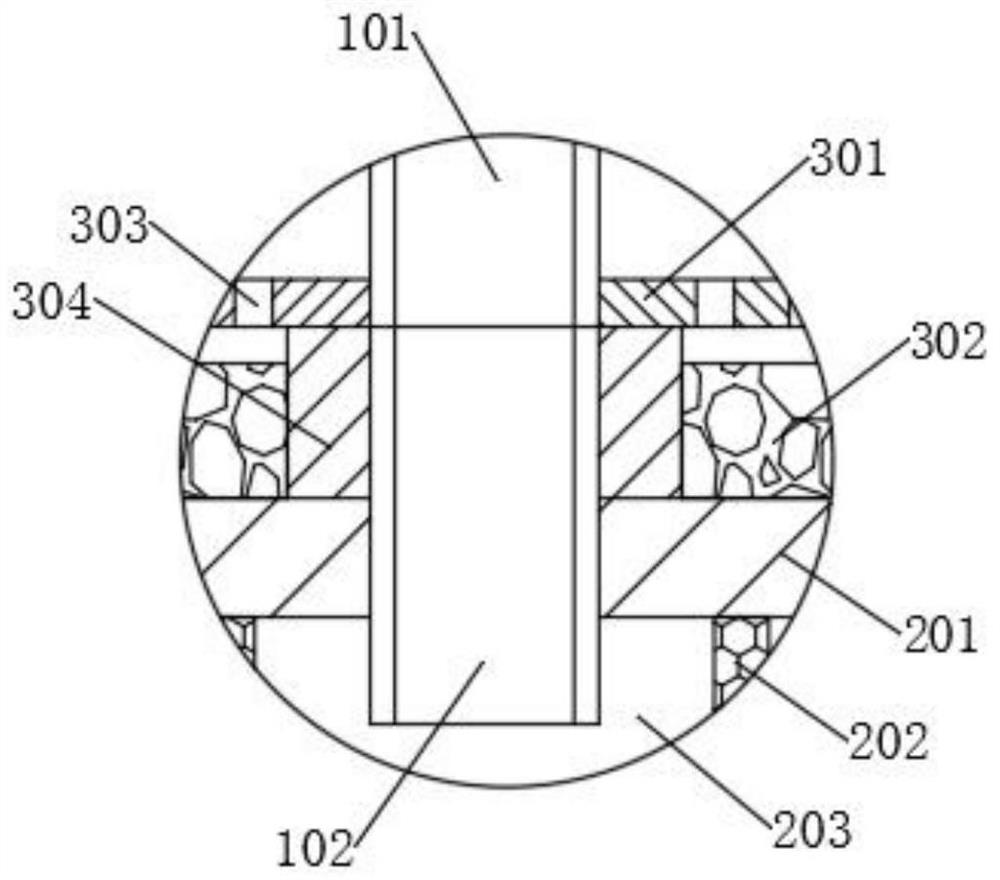

[0044] The invention discloses an environmental protection recovery equipment for waste heat of an autoclave used in the production of autoclaved aerated concrete slabs. Figure 1-Figure 8 As shown, it includes an autoclave main body 1, a waste heat recovery mechanism 2, a gas aroma mechanism 3, and an impurity removal mechanism 4.

[0045] Wherein, the middle part of the upper end of the autoclave main body 1 is connected with a pressure discharge pipe 101, and the pressure discharge pipe 101 communicates with the inside of the autoclave main body 1, and is used to transport the high-temperature gas in the autoclave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com