Cooling water distribution device for high-Mach-number spray pipe of conventional hypersonic wind tunnel

A hypersonic, high Mach number technology, applied in the direction of measuring devices, machine/structural parts testing, instruments, etc., can solve the problems of cumbersome installation, long cycle, high cost of cooling water supply system, etc., to achieve simple matching and reduce investment The effect of cost, operation and maintenance convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

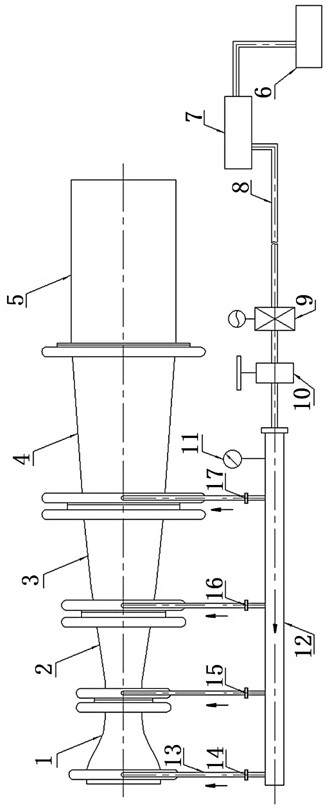

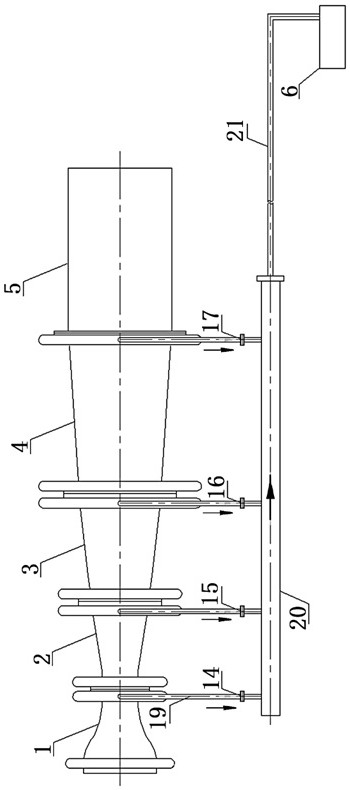

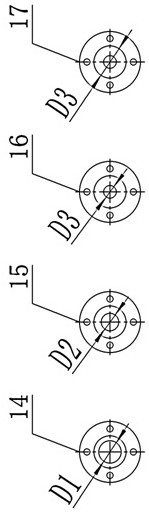

[0056] The nozzle of the present embodiment is a high Mach number nozzle of the order of 1 meter, such as figure 1 , figure 2 , Figure 4 As shown, the nozzle is divided into five sections, namely nozzle throat section I1, nozzle throat section II2, nozzle diffusion section I3, nozzle diffusion section II4, and nozzle diffusion section III5. The nozzle sections that need to be cooled are The 4 sections are nozzle throat section Ⅰ1, nozzle throat section Ⅱ2, nozzle diffusion section Ⅰ3 and nozzle diffusion section Ⅱ4, and 4 cooling circulation pipelines are configured accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com