Cloud-side collaborative logistics equipment control method and system

A technology of equipment control and logistics, applied in logistics, data processing applications, instruments, etc., can solve the problems of high control cost and low automation, achieve the effect of simple operation, improve automation, and avoid high cost of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A logistics equipment control method for cloud-side collaboration, including two modes of logistics terminal equipment being online or offline. The judgment of online or offline is based on whether the logistics terminal equipment establishes communication with the outside world, such as a cloud platform. If no communication is established with the outside world, it means logistics The terminal device is in offline mode, and establishing communication with the outside world means that the logistics terminal device is in online mode. When the logistics terminal equipment is in the online mode: collect and process data from several logistics terminal equipment; transmit the processed data to the cloud platform through the edge gateway, and the cloud platform analyzes the received data on the operation status and status of the logistics terminal equipment. At the same time, the cloud platform schedules the logistics terminal equipment through the edge gateway. The cloud pla...

Embodiment 2

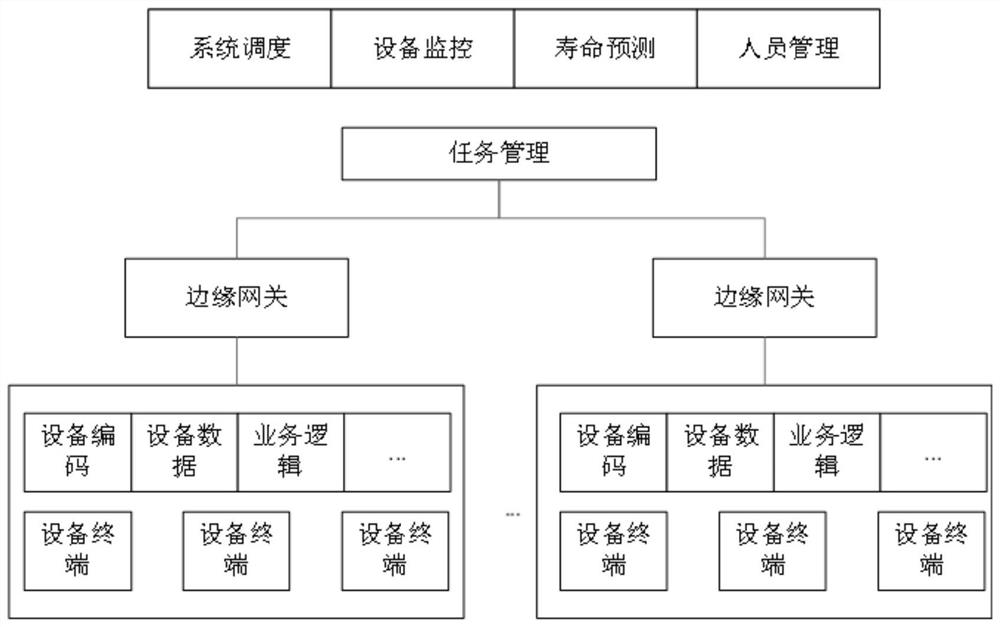

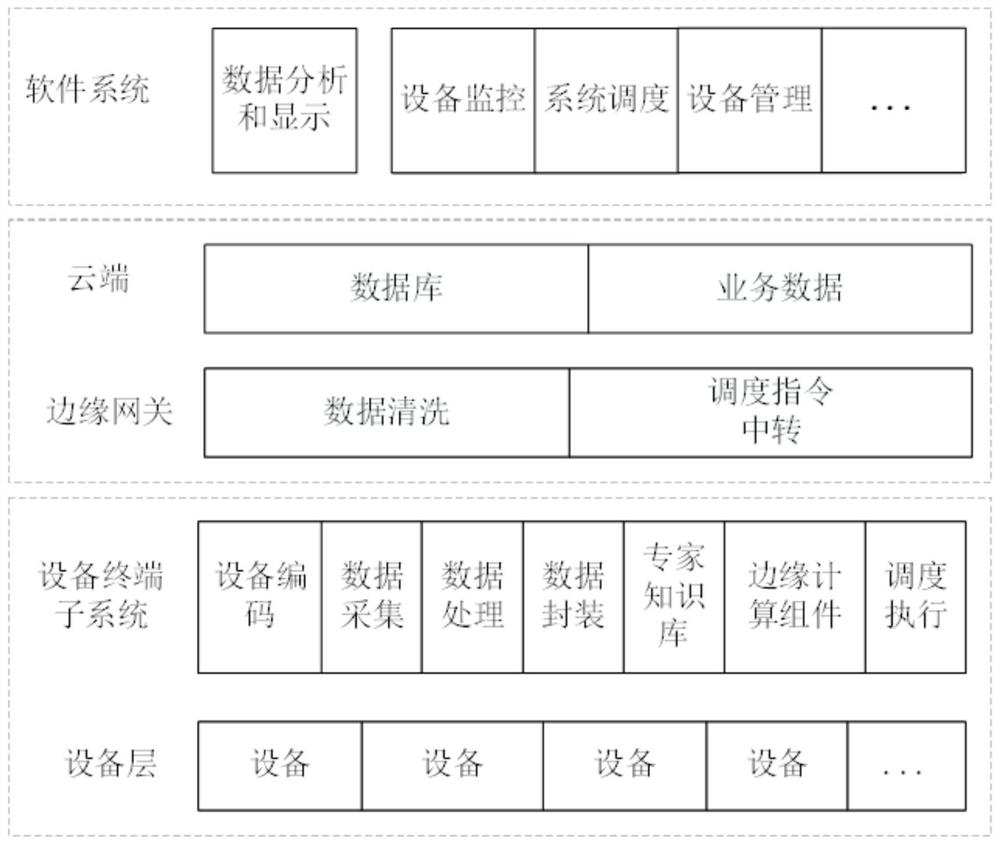

[0039] Such as figure 1 and figure 2 As shown, a system for implementing a cloud-edge collaborative logistics equipment control method as described in the above-mentioned embodiment 1 includes several logistics terminal control modules for controlling several different logistics terminal equipment, and the logistics terminal The control module is in one-to-one correspondence with the logistics terminal equipment, using a distributed framework, one control module corresponds to one device, and the mapping of the logistics terminal control module corresponds to the construction of the logistics terminal equipment scheduling data model; the construction of the logistics terminal equipment scheduling data model includes equipment data mapping and control System scheduling business logic mapping. The cloud platform used to monitor and dispatch the logistics terminal control module, the cloud platform is used to provide services to users and dispatch equipment. The edge gateway m...

Embodiment 3

[0050] The control method using the system in embodiment 2 includes online mode and offline mode, and the online mode control method is as follows:

[0051] S1. Docking thread equipment, the encoding component in the logistics terminal control module encodes the logistics terminal equipment;

[0052] S2. The data collection component collects the physical and operational information data of the equipment;

[0053] S3. The data encapsulation component encapsulates the data collected by the device and the device code;

[0054] S4. The logistics terminal control module uploads the encapsulated data to the edge gateway module;

[0055]S5. The edge gateway module sets data cleaning rules, performs data cleaning on the uploaded data, converts the data into relational data available for business and uploads it to the cloud platform;

[0056] S6. The cloud platform needs to receive and store the data uploaded by the edge gateway module;

[0057] S7. The data analysis and display mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com